Preparation of porosity electrospun fiber

An electrospun fiber and porous technology, which is applied in the field of preparation of porous electrospun fibers, can solve problems such as application limitations, and achieve the effects of good shape, broad application prospects and simple operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

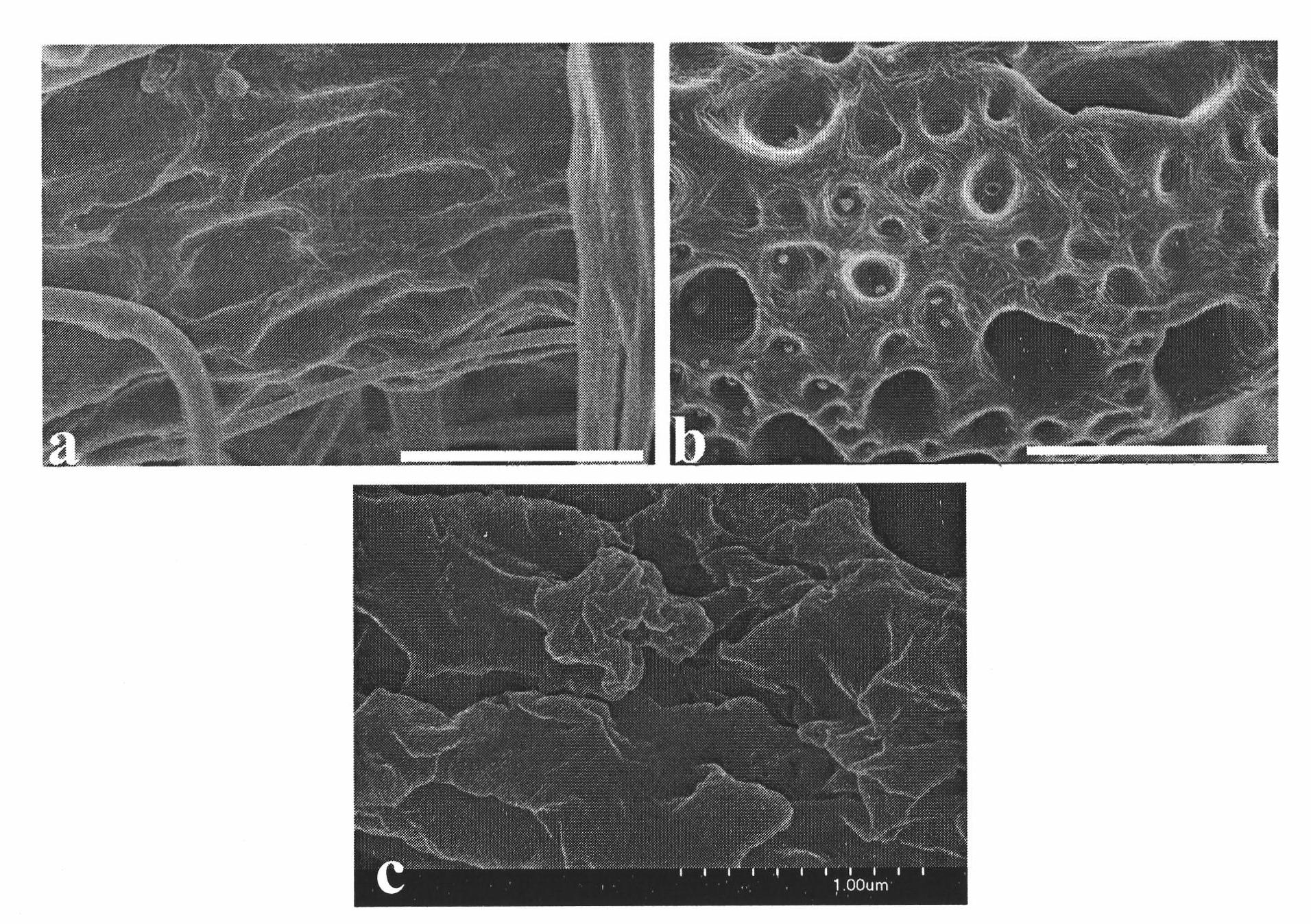

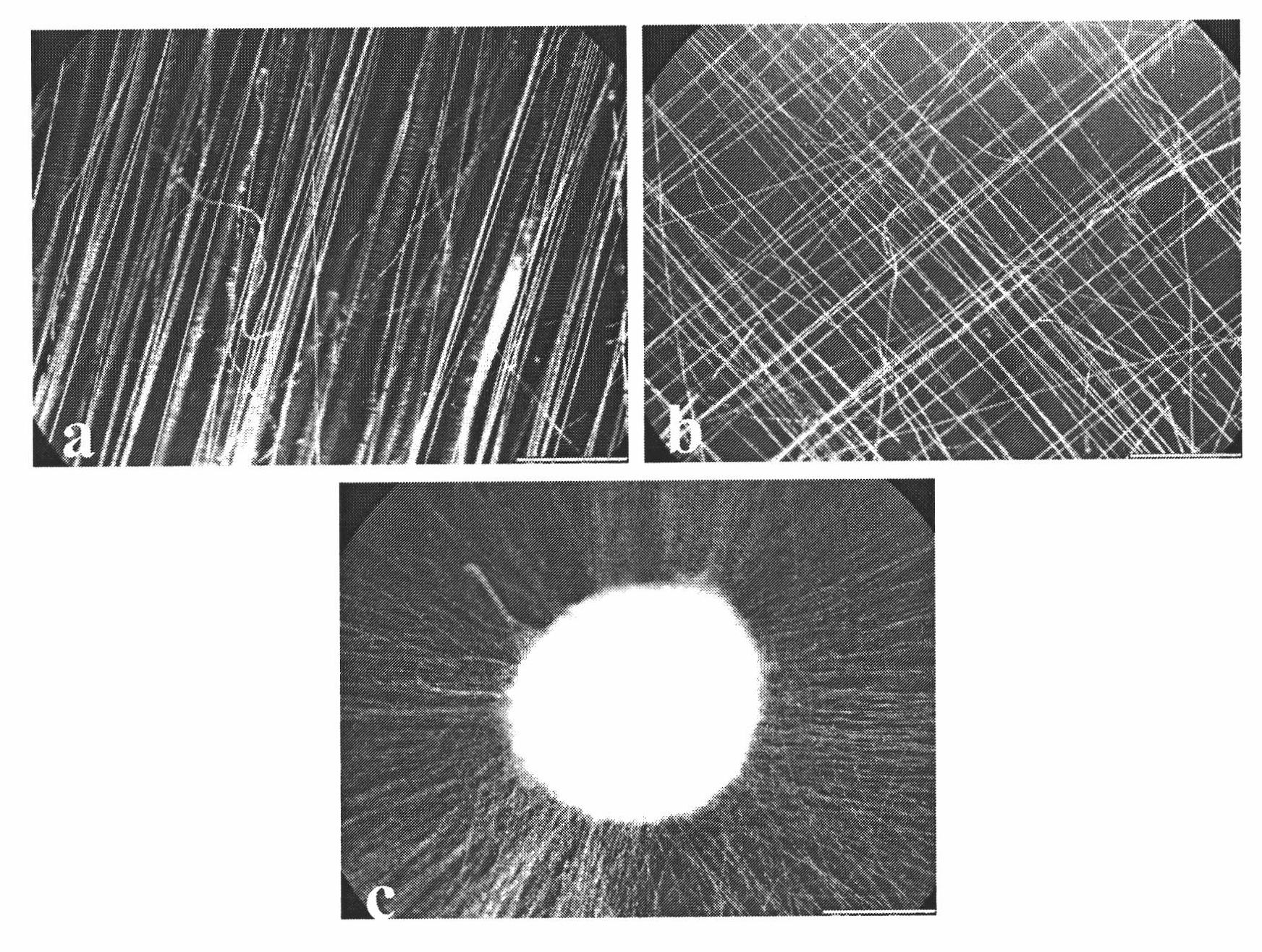

[0026] Embodiment 1, preparation of porous electrospun fiber membrane

[0027] Include the following steps:

[0028] a, preparation of electrospinning solution: dissolving polycaprolactone (PCL) in methanol to make a solution with a mass volume percentage of 5%, adding sodium chloride (NaCl) with a particle size of 1 μm in the solution to make PCL and NaCl The mass ratio of the mixture is 1:1, and the mixture is evenly mixed to obtain the PCL / NaCl mixed electrospinning solution;

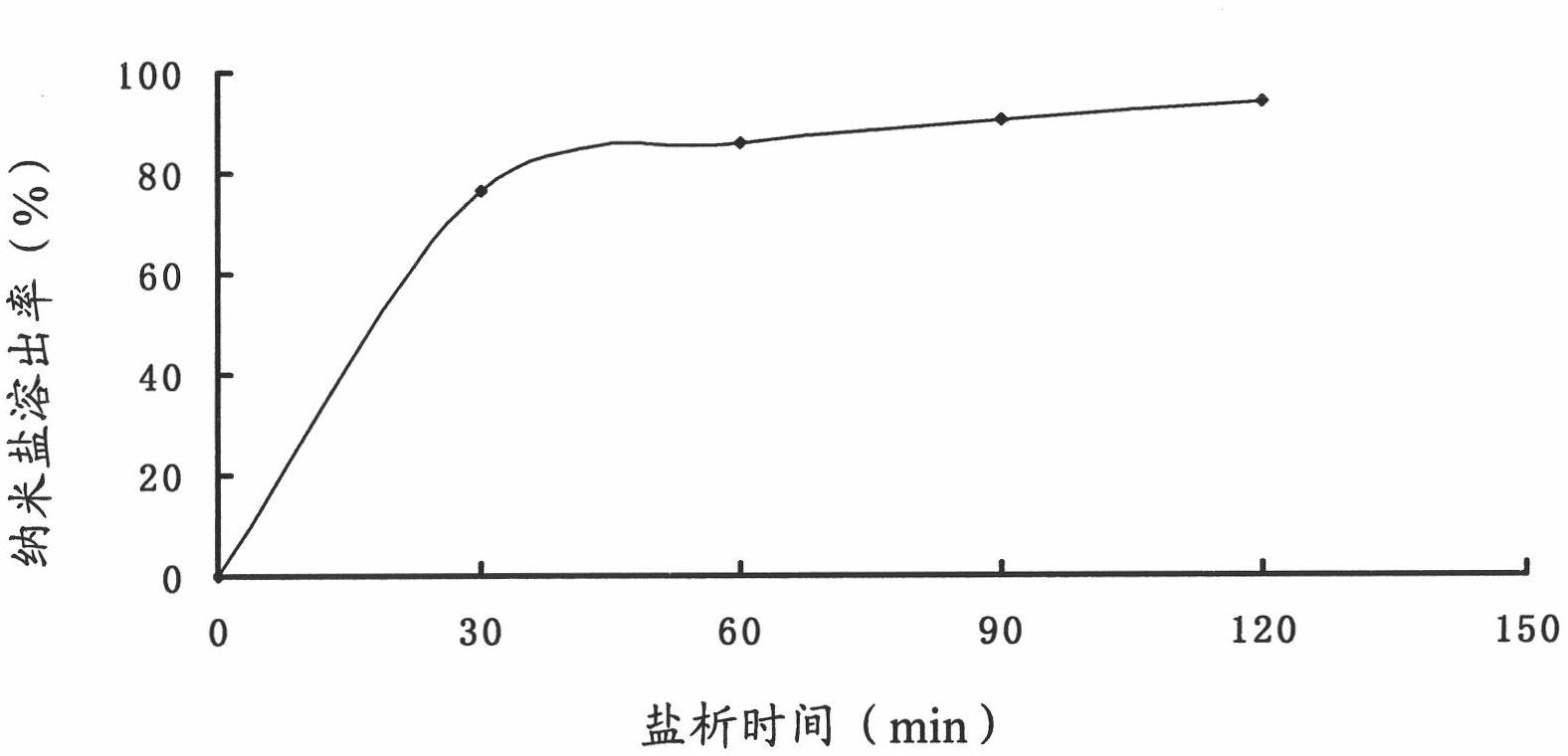

[0029] b. Electrospinning: use the electrospinning equipment (with stainless steel metal plate as the receiver) of the PCL / NaCl mixed electrospinning solution in step a at an applied voltage of 20KV, a flow rate of the electrospinning solution of 0.01mL / min, and a receiving distance of 5cm Electrospinning was carried out under certain conditions to obtain PCL / NaCl composite electrospun fibers, and the receiver collected the fibers for 60 minutes to obtain PCL / NaCl composite electrospun fiber membran...

Embodiment 2

[0032] Embodiment 2, preparation of porous electrospun fiber membrane

[0033] Include the following steps:

[0034] a, preparation of electrospinning solution: dissolving PCL in chloroform to make a solution with a mass volume percentage of 9%, adding calcium carbonate (CaCO3) with a particle size of 100nm in the solution 3 ) make PCL and CaCO 3 The mass ratio of the mixture is 1:1, mix evenly to get PCL / CaCO 3 Mixed electrospinning solution;

[0035] b. Electrospinning: the PCL / CaCO of step a 3 The electrospinning equipment (using stainless steel metal plate as the receiver) for the mixed electrospinning solution was electrospun under the conditions of an applied voltage of 20KV, a flow rate of the electrospinning solution of 0.015mL / min, and a receiving distance of 15cm to obtain PCL / CaCO 3 Composite electrospun fibers, the receiver collected the fibers for 60 minutes, and obtained PCL / CaCO with randomly arranged fibers 3 Composite electrospun fiber membrane;

[0036] c...

Embodiment 3

[0038] Embodiment 3, preparation of porous electrospun fiber membrane

[0039] Include the following steps:

[0040] a, preparation of electrospinning solution: dissolving polyglycolic acid (PGA) in hexafluoroisopropanol to make a solution with a mass volume percentage of 10%, adding sodium bicarbonate (NaHCO 3 ) make PGA with NaHCO 3 The mass ratio of the mixture is 2:1, mix evenly to get PGA / NaHCO 3 Mixed electrospinning solution;

[0041] b, electrospinning: the PGA / NaHCO of step a 3 Electrospinning equipment (with stainless steel metal plate as the receiver) was used to electrospin the mixed electrospinning solution under the conditions of an applied voltage of 5KV, a flow rate of the electrospinning solution of 0.02mL / min, and a receiving distance of 5cm to obtain PGA / NaHCO 3 Composite electrospun fibers, the receiver collects the fibers for 60 minutes, and obtains PGA / NaHCO with randomly arranged fibers 3 Composite electrospun fiber membrane;

[0042] c, salting ou...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com