Novel acoustical-electrical converter and microphone

An acousto-electric converter and microphone technology, applied in piezoelectric/electrostrictive transducer microphones, piezoelectric/electrostrictive transducers, sensors, etc., can solve the difficulty of parts processing and the improvement of assembly accuracy, and the volume of the microphone. It is impossible to achieve small problems, performance and structural bottlenecks, etc., to achieve the effect of simplifying the manufacturing process, reducing the number of parts, and low manufacturing costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

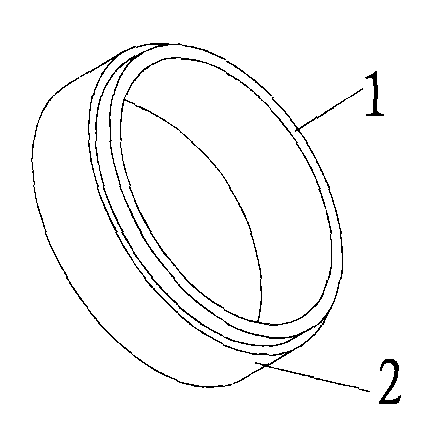

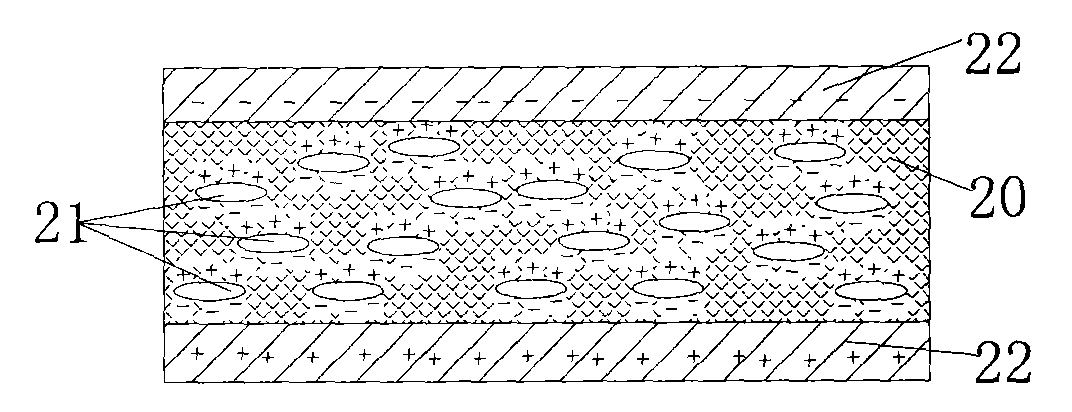

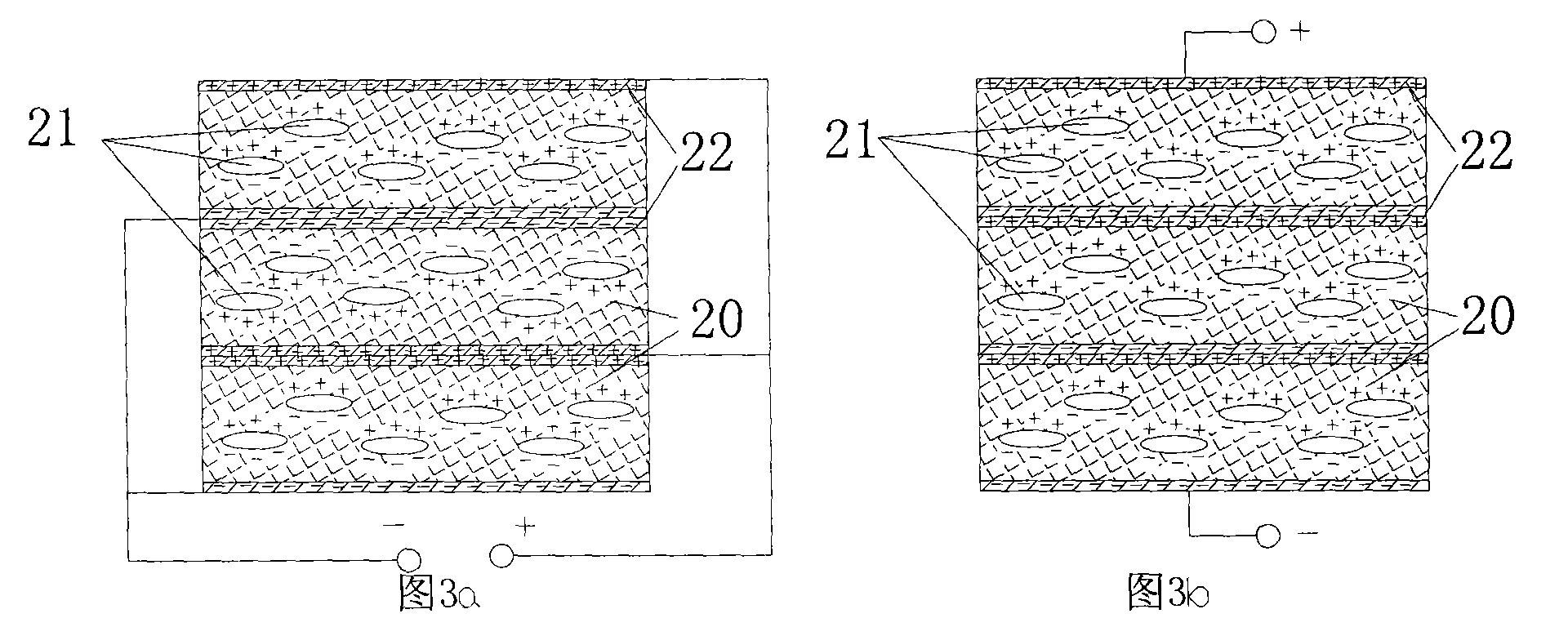

[0033] The acoustic-electric transducer of this specific embodiment is as figure 1 As shown, it includes a copper ring 1 and an acoustic-electric conversion unit. The acoustic-electric conversion unit is a piezoelectric film 2 wound on the periphery of the copper ring 1, and the number of wound layers is one or more than one. The piezoelectric film 2 is made by cutting a porous polymer piezoelectric film, and its structure is as follows: figure 2 As shown, it includes a porous polymer piezoelectric film 20 and a metal layer 22 covering the porous polymer piezoelectric film 20 . The porous polymer piezoelectric film 20 contains a plurality of closed pore structures 21 , and one end of each pore structure 21 close to the upper surface of the porous polymer piezoelectric film 20 is positively charged, and one end close to the lower surface is negatively charged. The metal layer 22 is a layer of metal evaporated on the upper and lower surfaces of the porous polymer piezoelectri...

specific Embodiment approach 2

[0048] The micro-acoustoelectric conversion device of this specific embodiment, such as Figure 5 As shown, it includes: a tube core 15 and an acoustic-electric conversion unit, the acoustic-electric conversion unit is used for converting sound signals into electrical signals, and the tube core 15 is used for primary amplification of the electrical signals. The die 15 has a gate 16 serving as a signal input, a signal output 18 for outputting a signal, and a ground 17 . The acoustic-electric conversion unit is a piezoelectric film 2 wound around the die 15 . One side of the piezoelectric film 2 is signal-connected to the gate 16 , and the other side is signal-connected to the ground terminal 17 . In this specific embodiment, the outer surface of the piezoelectric film 2 is connected to the ground terminal 17 of the die 15 through the ground connector 14 .

[0049] When external sound waves act on the piezoelectric film, the piezoelectric film generates charges between the upp...

specific Embodiment approach 3

[0050] Traditional remote control such as Image 6 As shown, it includes a wire rod and a wire control box 33 somewhere in the wire rod. The microphone 32 is arranged in the wire control box 33 . The wire includes at least one ground wire 30 and one signal wire 31 arranged in parallel. The microphone 32 is electrically connected to the ground line 30 and the signal line 31 , respectively.

[0051] The flexible acoustic-electric transducer of this specific embodiment, such as Figure 7 with Figure 8 As shown, including: wire and sound-electric conversion unit. Wherein the wire includes at least one signal line 31 and one grounding line 30 arranged in parallel, and there is an insulating material between the signal line and the grounding line to keep the insulation between the two; and the acoustic-electric conversion unit includes a grounding ring 34 and a voltage Electrofilm 2. The piezoelectric film 2 is wound around the periphery of the wire, and the portion of the si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com