Bio-additive premixed feed special for pigs and method for preparing bioactive substance carrier thereof

A bioactive substance and premixed feed technology, applied in animal feed, animal feed, application, etc., can solve the problems of ineffective treatment, delay in the best time for treatment, and reduced drug effect, so as to enhance immune stress ability, increase digestibility, and increase litter depth

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0102] The preparation method of the bioactive substance carrier of the present invention, the detailed steps of the preparation method are as follows:

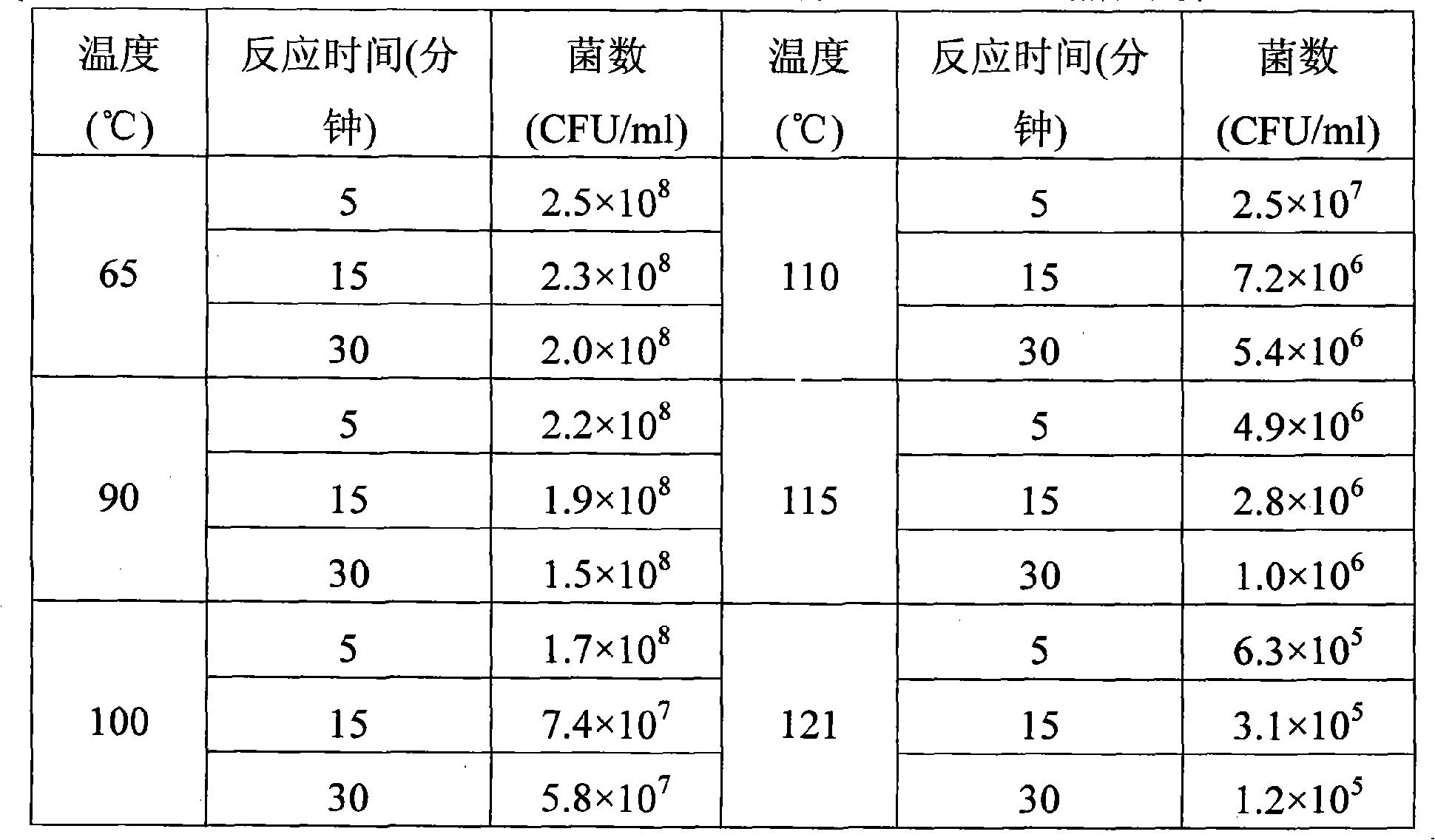

[0103] a. Preparation of Bacillus subtilis natto subspecies Chou 007 liquid bioactive substance:

[0104] First dilute the molasses with sterile water to a concentration of 6.5 brix measured by a sugar meter. After sterilizing at 100°C for 15 minutes, take 4000L and put it into a fermenter. Bean subspecies Chou 007 bacterial liquid (the number of Bacillus subtilis subspecies Chou 007 in the bacterial liquid is ≥1.2×108 CFU / ml, pH 6.0~6.5) 500L is poured into the fermenter, and then 10% skimmed milk powder and 1% disodium hydrogen phosphate have been prepared in the sterilized tank with 1000L sterile water After the nutrient source aqueous solution is sterilized at 100°C for 15 minutes, take 500L and put it into a fermenter. After adding it, the concentrations of skimmed milk powder and disodium hydrogen phosphate relative to ...

Embodiment 2

[0113] The preparation method of the bioactive substance carrier of the present invention is basically the same as that of Example 1, except that:

[0114] Step a: Dilute the molasses with sterile water to a concentration of 10brix. After the diluted molasses is sterilized, take 3500L and put it into a fermenter. Take 1000L of sterilized skimmed milk powder and disodium hydrogen phosphate nutrient source aqueous solution. After adding, skim The concentrations of milk powder and disodium hydrogen phosphate relative to molasses are 2% and 0.2% respectively, the fermentation temperature is 25°C, and the fermentation time is 60 hours. The added decomposing enzyme is α-amylolytic enzyme, and the added amount is 10% of that used in step c. 0.05% of the total amount of solid substrate;

[0115] Step b: first dilute the molasses with sterile water to a concentration of 10brix, take 4250L of the diluted molasses after sterilization and put it into a fermenter, take 250L of sterilized s...

Embodiment 3

[0120] The preparation method of the bioactive substance carrier of the present invention is basically the same as that of Example 1, except that:

[0121] Step a: Dilute the molasses with sterile water to a concentration of 15 brix. After the diluted molasses is sterilized, take 3800L and put it into a fermenter. Take 700L of sterilized skimmed milk powder and disodium hydrogen phosphate nutrient source aqueous solution, add it and then skim it The concentrations of milk powder and disodium hydrogen phosphate relative to molasses are respectively 1.5% and 0.15%, the fermentation temperature is 60°C, and the fermentation time is 5 hours. 0.10% of the total solid substrate;

[0122] Step b: first dilute the molasses with sterile water to a concentration of 15brix, then take 3800L of the diluted molasses and put it into a fermenter after sterilization, and take 700L of sterilized skimmed milk powder, anhydrous dipotassium phosphate and 7 times hydrated sulfuric acid Magnesium n...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com