Horizontal turning wheel spray washing plasma and photocatalytic air-purification equipment

A technology of air purification equipment and plasma, which is applied in the direction of lighting and heating equipment, air humidification system, heating method, etc., can solve problems such as reduction, achieve the effect of simplifying equipment structure, good uniformity, and improving purification degree

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

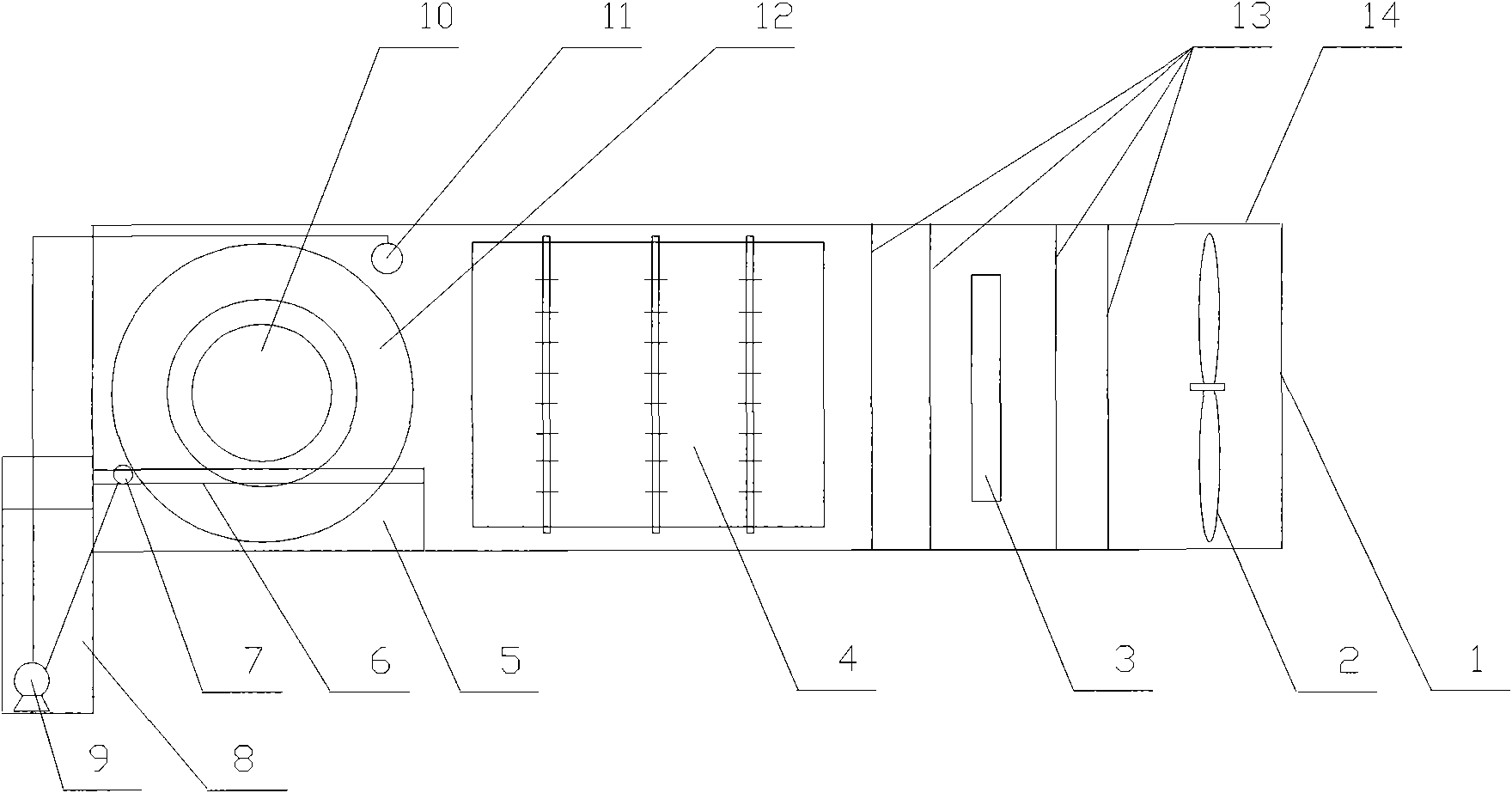

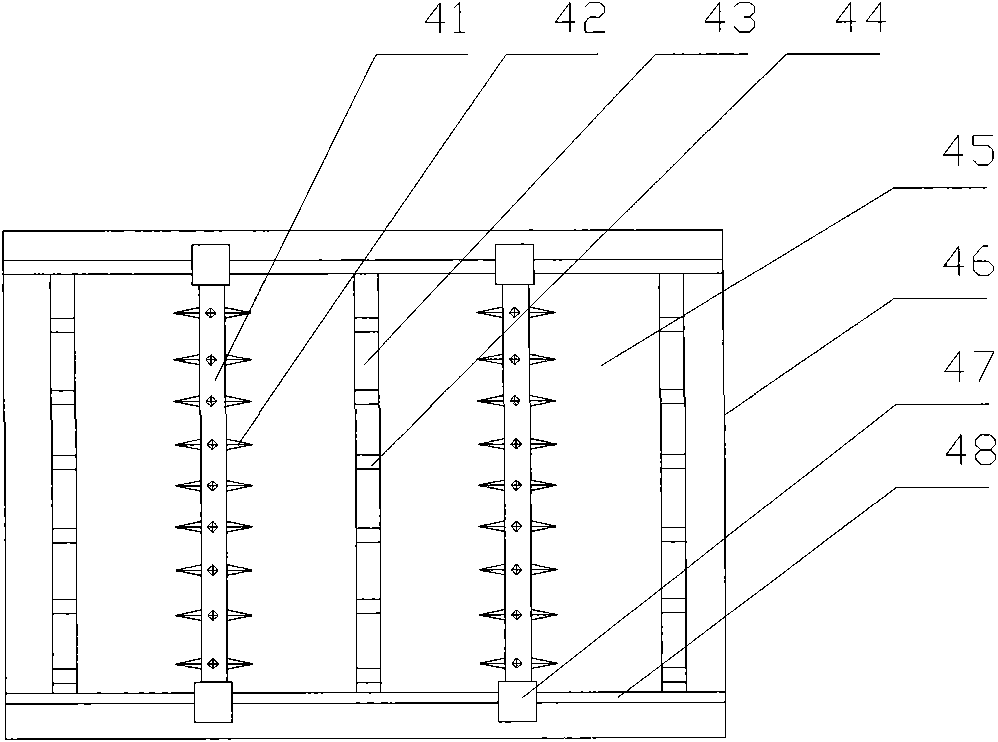

[0010] see figure 1 and figure 2 , the present invention provides a plasma and photocatalytic air purification equipment for horizontal runner spray washing, including a housing 14, which is divided into a runner humidification chamber and a plasma purification chamber from front to back. 4 and a photocatalytic reaction chamber, the said runner humidification chamber is provided with an annular humidification runner 11, and the bottom is a water tank 5 which can immerse the bottom of said humidification runner, said plasma purification chamber includes a plurality of parallel and equidistant The vertical flat plate 43 that is set, is evenly distributed with some discharge rods 41 between described each flat plate, has some uniformly distributed discharge thorns 42 on the surface of described discharge rod, and described vertical flat plate is connected with the negative pole of power supply, and described Discharge rod is connected with the positive pole of described power s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com