Bacterial cellulose carbon paste electrode and preparation method thereof

A bacterial cellulose and carbon paste electrode technology, applied in the field of electrodes, can solve the problems that have not yet been seen, and achieve the effects of easy popularization, improved sensitivity, and good catalytic effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

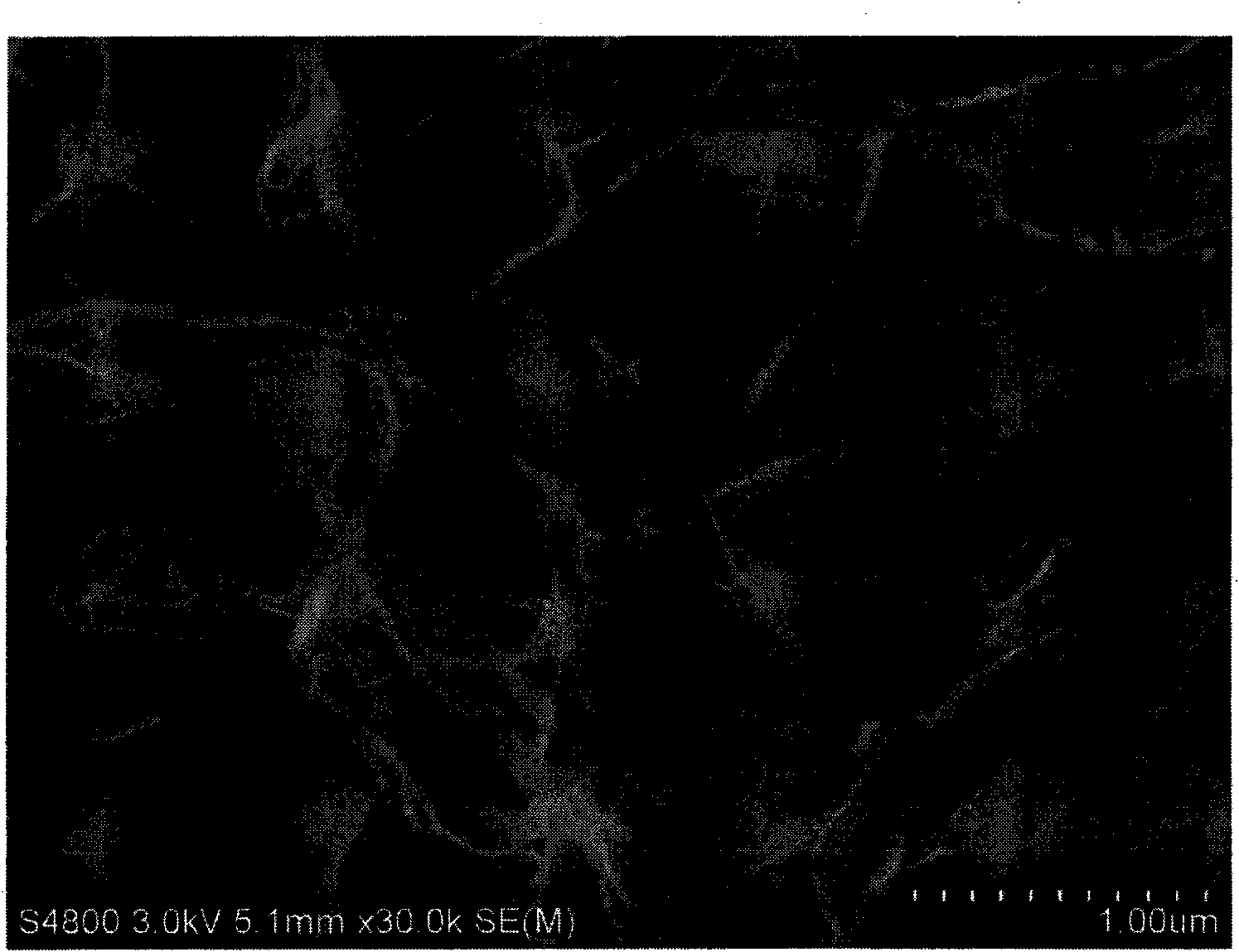

[0032] A bacterial cellulose carbon paste electrode mainly consists of an outer sleeve (which is a polytetrafluoroethylene sleeve with an inner diameter of 3mm), a screw rod (generally a copper screw rod) connected to the inner thread of the outer sleeve at one end, and filled in the outer sleeve. The carbon paste composition (structure is the same as prior art); The carbon paste is fully mixed with 40mg carbonized bacterial cellulose and 70ul silicone oil;

[0033] The preparation method of the bacterial cellulose carbon paste electrode is as follows: 40 mg of carbonized bacterial cellulose is fully mixed with 70 ul of silicone oil, and then the mixture is packed into an outer sleeve and compacted to obtain the bacterial cellulose carbon paste electrode product.

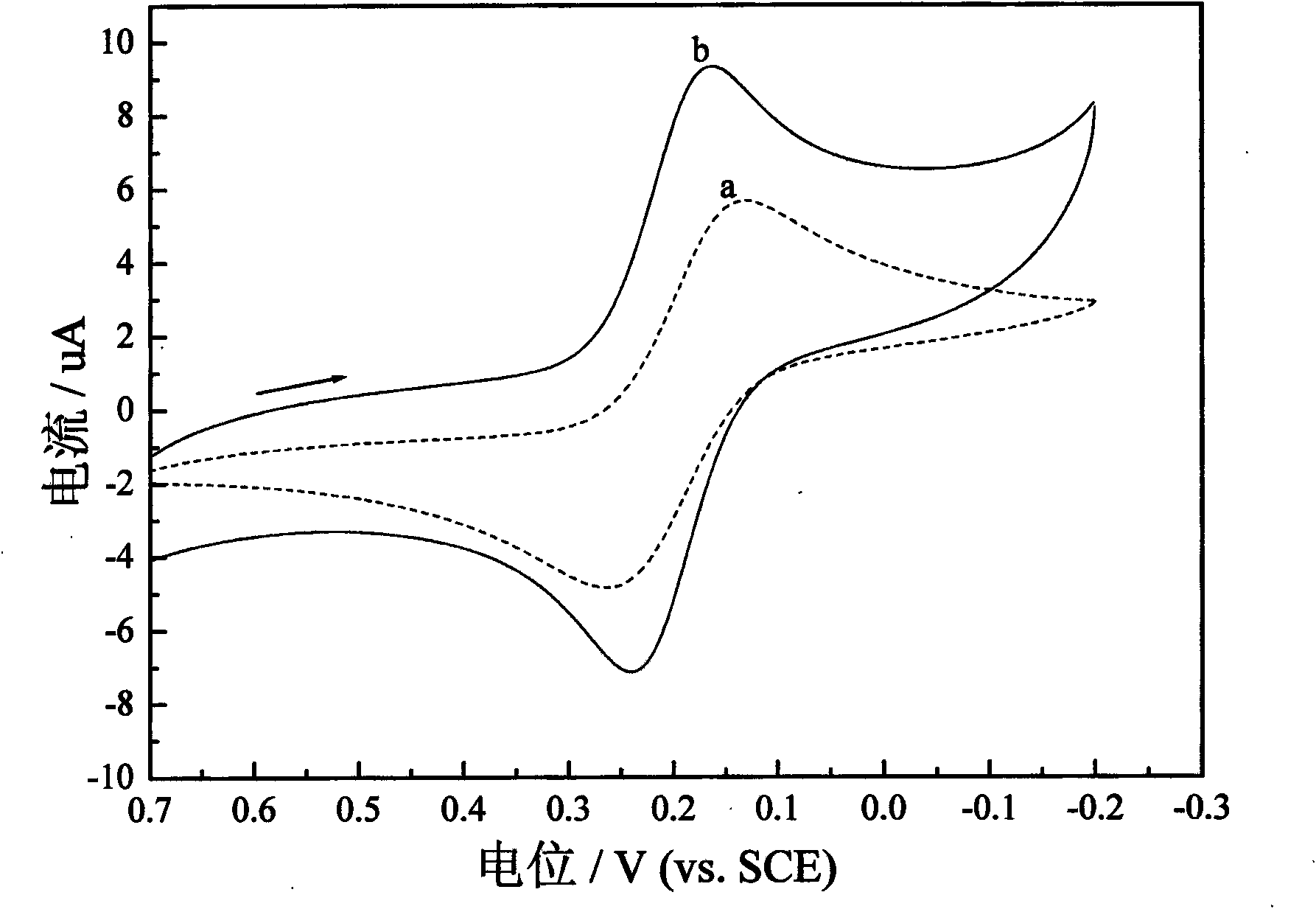

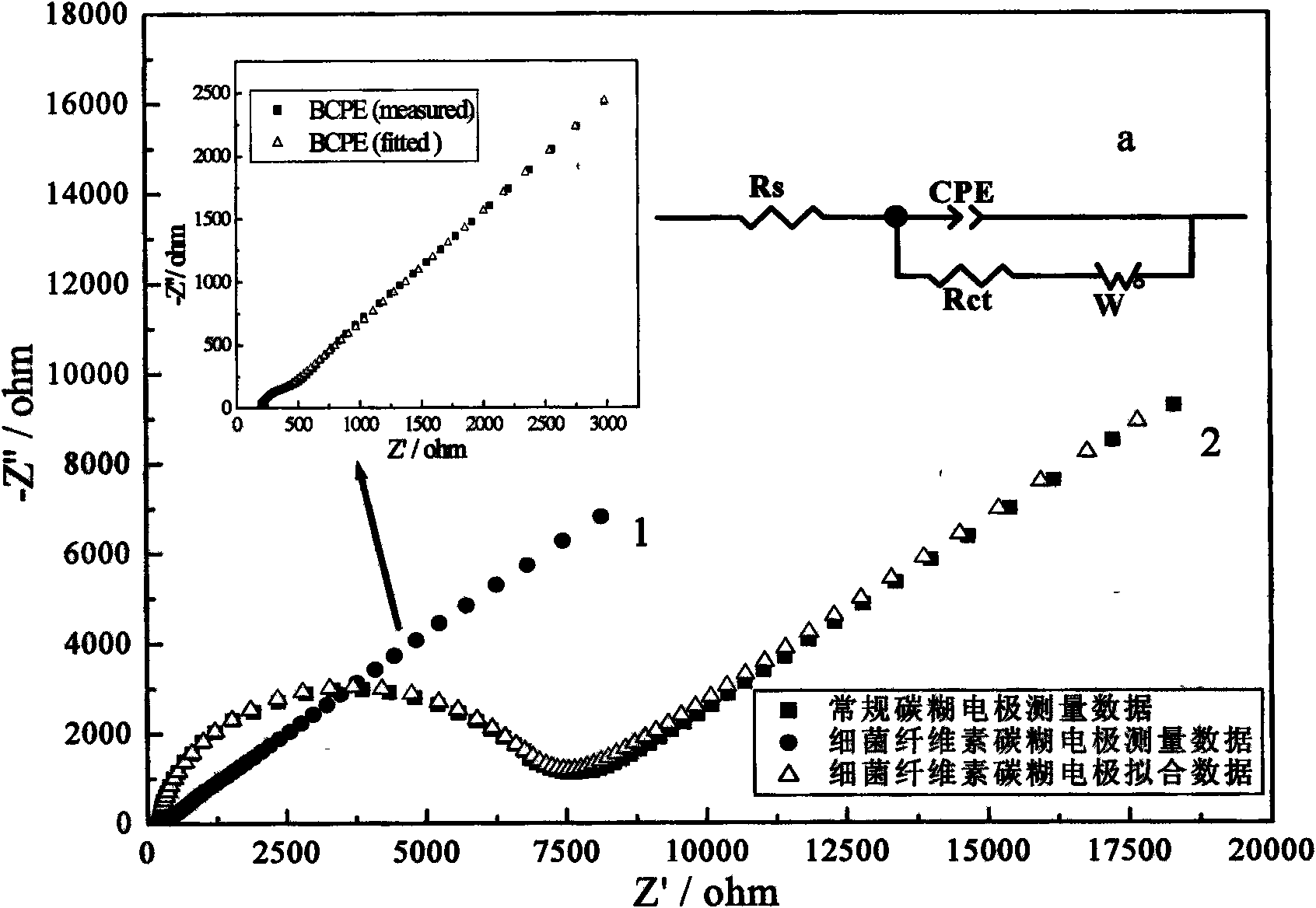

[0034] The bacterial cellulose carbon paste electrode of this embodiment is placed in the mixed solution of 1 mmol / L potassium ferricyanide and 0.1 mol / L potassium chloride, within the potential range of 0.8~-0.2V, p...

Embodiment 2

[0037] A bacterial cellulose carbon paste electrode mainly consists of: an outer sleeve (a polytetrafluoroethylene sleeve with an inner diameter of 3mm), a screw rod (generally a copper screw rod) connected to the inner thread of the outer sleeve at one end, and a screw rod filled in the outer sleeve The composition of the carbon paste in the tube (the structure of the carbon paste electrode is the same as that of the prior art); the carbon paste is a mixture obtained by uniformly mixing carbonized bacterial cellulose and a hydrophobic organic solvent.

[0038]The preparation method of the bacterial cellulose carbon paste electrode is to take 40mg of bacterial cellulose that has been carbonized at 900°C for 3 hours under a nitrogen atmosphere and fully mix it with 70ul of silicone oil, then put the mixture into the outer casing and compact it to obtain the bacterial cellulose Plain carbon paste electrode products.

[0039] Using potassium ferricyanide solution as a probe, the ...

Embodiment 3

[0041] A bacterial cellulose carbon paste electrode, which mainly consists of: an outer casing (which is a polytetrafluoroethylene casing), a screw rod (generally a copper screw rod) connected to the inner thread of the outer casing at one end, and carbon paste filled in the outer casing Composition (the structure of the carbon paste electrode is the same as that of the prior art); the carbon paste is a mixture obtained by uniformly mixing carbonized bacterial cellulose and a hydrophobic organic solvent.

[0042] The preparation method of the bacterial cellulose carbon paste electrode is to take 80mg of bacterial cellulose that has been carbonized at 1000°C for 2 hours under a nitrogen atmosphere and fully mix it with 150ul silicone oil, then put the mixture into the outer casing and compact it to obtain the bacterial cellulose Plain carbon paste electrode products.

[0043] Others are the same as embodiment 1 or embodiment 2, and have characteristics and beneficial effects de...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The inside diameter of | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com