Bismuth telluride bulk nanometer material and preparation method thereof

A bulk material, bismuth telluride technology, applied in the direction of binary selenium/tellurium compounds, etc., can solve the problem of difficulty in preparing nanocrystalline bulk materials with controllable grain size, etc., and achieves low pressure and low sintering temperature. , the effect of simple process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

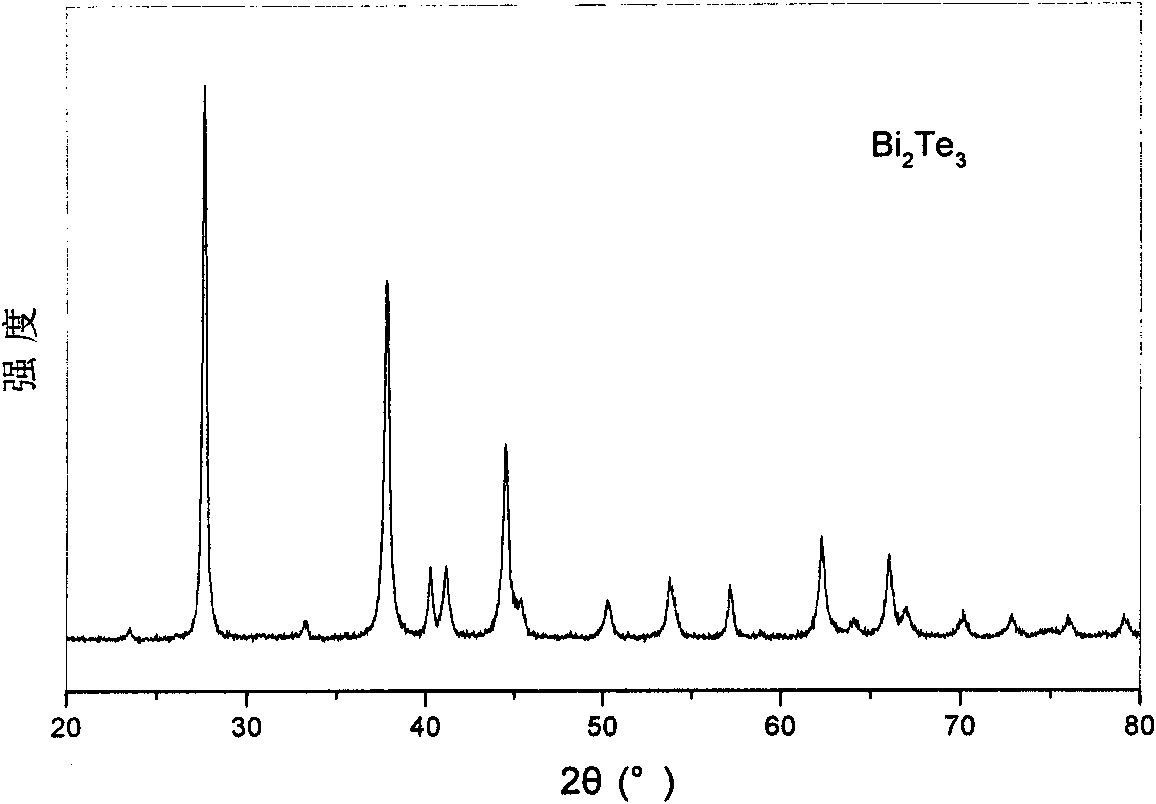

Embodiment 1

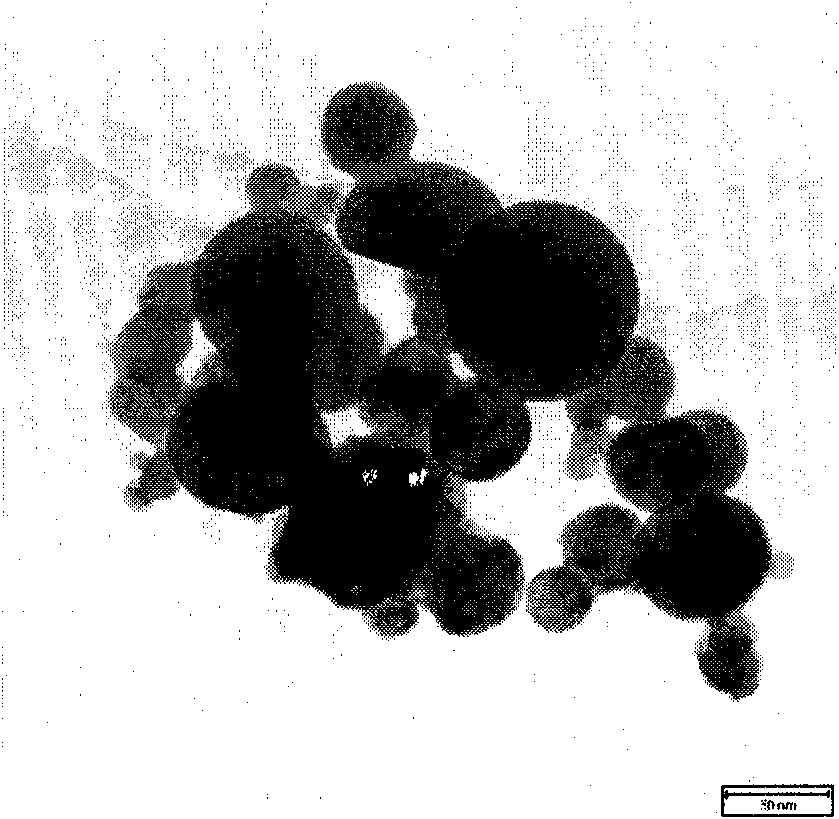

[0022] 1) DC arc evaporation and condensation equipment is used, with the single mass of Te as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.1MPa, the reaction current is 40A, the voltage between the anode and the cathode is 50V, and the reaction time is 20min. Obtain Te nanopowder of 10-40nm;

[0023] 2) Using direct current arc evaporation and condensation equipment, using the single mass of Bi as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.1MPa, the reaction current is 40A, the voltage between the anode and the cathode is 50V, and the reaction time is 20min. Obtain Bi nanopowder of 10-30nm;

[0024] 3) Put Te nanopowder and Bi nanopowder in an argon atmosphere with an oxygen content of 0.05ppm in a molar ratio of 3:2, grind and mix them and put them into a graphite mold with a diameter of 20mm;

[0025] 4) Place the mold in the SPS sintering cavity, apply an axial pressure of 30MPa, s...

Embodiment 2

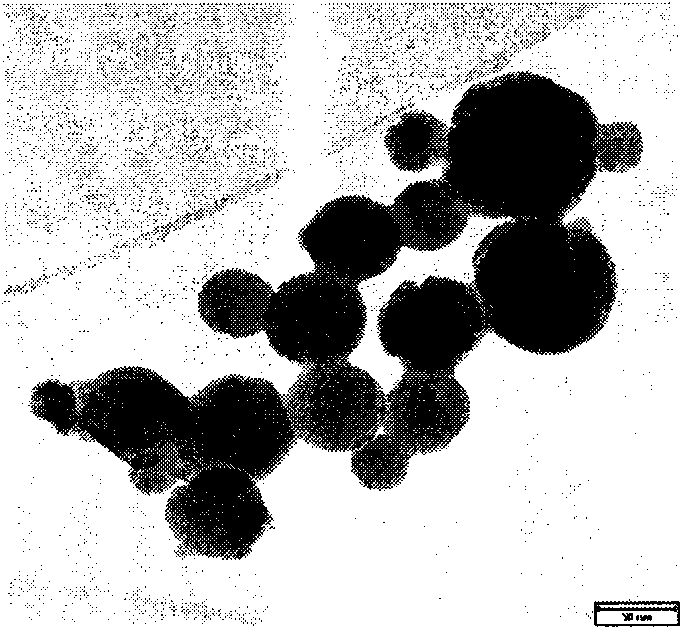

[0028] 1) DC arc evaporation and condensation equipment is used, with the single mass of Te as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.05MPa, the reaction current is 60A, the voltage between the anode and the cathode is 30V, and the reaction time is 30min. Obtain Te nanopowder of 10-40nm;

[0029] 2) Using direct current arc evaporation and condensation equipment, using the simple mass of Bi as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.05MPa, the reaction current is 60A, the voltage between the anode and the cathode is 30V, and the reaction time is 30min. Obtain Bi nanopowder of 10-40nm;

[0030] 3) Put Te nanopowder and Bi nanopowder in an argon atmosphere with an oxygen content of 0.05ppm in a molar ratio of 3:2, grind and mix them and put them into a graphite mold with a diameter of 20mm;

[0031] 4) Place the mold in the SPS sintering cavity, apply an axial pressure of 40MPa,...

Embodiment 3

[0034] 1) DC arc evaporation and condensation equipment is adopted, with the single mass of Te as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.05MPa, the reaction current is 100A, the voltage between the anode and the cathode is 40V, and the reaction time is 40min. Obtain Te nanopowder of 20-50nm;

[0035] 2) Using direct current arc evaporation and condensation equipment, using the simple mass of Bi as the anode and metal tungsten as the cathode, in an atmosphere with an argon pressure of 0.05MPa, the reaction current is 80A, the voltage between the anode and the cathode is 40V, and the reaction time is 40min. Prepare 20-50nm Bi nanopowder;

[0036] 3) Te nano-powder and Bi nano-powder are put into a graphite mold with a diameter of 20 mm after being ground and mixed in an argon atmosphere with an oxygen content of 0.1 ppm in a molar ratio of 3:2;

[0037] 4) Place the mold in the SPS sintering cavity, apply an axial pressure of 5...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grain size | aaaaa | aaaaa |

| Bending strength | aaaaa | aaaaa |

| Grain size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com