Erdosteine composition and preparation method thereof

A composition and uniform mixing technology, applied in the field of medicine, can solve the problems of poor bioavailability of common dosage forms, microcrystalline cellulose is not suitable for disintegrating agents, and poor solubility of erdosteine, so as to improve the drug delivery effect, The effect of high drug dissolution efficiency and simple and easy preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

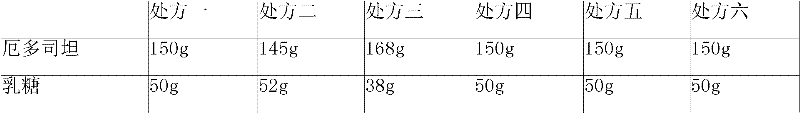

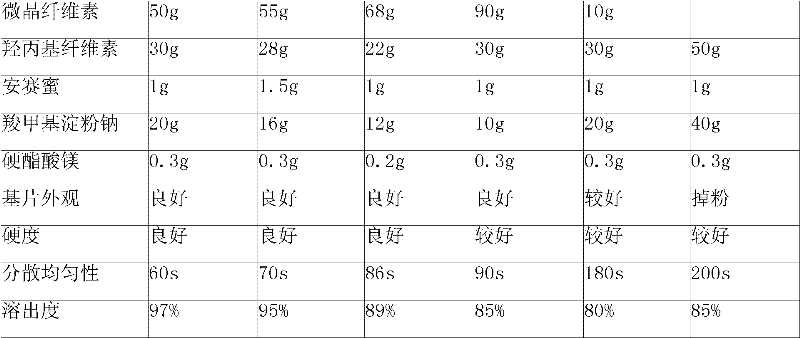

[0054] Erdosteine 150g

[0055] Lactose 50g

[0056] Microcrystalline Cellulose 50g

[0057] Low-substituted hydroxypropyl cellulose 30g

[0058] Acesulfame K 1g

[0059] Sodium carboxymethyl starch 20g

[0060] Magnesium stearate 0.3g

[0061] Made into 1000 pieces

[0062] Pass the prescribed amount of microcrystalline cellulose and low-substituted hydroxypropyl cellulose through an 80-mesh sieve, and pass through a 120-mesh sieve for lactose, acesulfame potassium, and sodium carboxymethyl starch. Mix erdosteine and low-substituted hydroxypropyl cellulose evenly, pulverize them with a ball mill, pass through a 100-mesh sieve, add sodium carboxymethyl starch, dry-blend with a high-speed mixing granulator at a speed of 45 rpm, and mix for 10 minutes , after adding 20ml of absolute ethanol, perform wet mixing at a speed of 30 rpm, mix for 3 minutes, then wet mix and cut for 2 minutes, transfer the prepared wet granules into a boiling dryer, and dry at 65°C for 20 to 2...

Embodiment 2

[0064] Erdosteine 150g

[0065] Lactose 50g

[0066] Microcrystalline Cellulose 50g

[0067] Low-substituted hydroxypropyl cellulose 30g

[0068] Acesulfame K 1g

[0069] Sodium carboxymethyl starch 20g

[0070] Magnesium stearate 0.3g

[0071] Made into 1000 pieces

[0072] Pass the prescribed amount of microcrystalline cellulose and low-substituted hydroxypropyl cellulose through a 70-mesh sieve, and pass through a 100-mesh sieve for lactose, acesulfame potassium, and sodium carboxymethyl starch. Mix erdosteine and low-substituted hydroxypropyl cellulose evenly, pulverize them with a ball mill, pass through a 100-mesh sieve, add sodium carboxymethyl starch, dry-mix with a high-speed mixing granulator at a speed of 35 rpm, and mix for 5 minutes , after adding 20ml of absolute ethanol, perform wet mixing at a speed of 30 rpm, mix for 3 minutes, then wet mix and cut for 2 minutes, transfer the prepared wet granules into a boiling dryer, and dry at 60°C for 15 to 20 mi...

Embodiment 3

[0074] Erdosteine 150g

[0075] Lactose 50g

[0076] Microcrystalline Cellulose 50g

[0077] Low-substituted hydroxypropyl cellulose 30g

[0078] Acesulfame K 1g

[0079] Sodium carboxymethyl starch 20g

[0080] Magnesium stearate 0.3g

[0081] Made into 1000 pieces

[0082] Pass the prescribed amount of microcrystalline cellulose and low-substituted hydroxypropyl cellulose through an 80-mesh sieve, and pass through a 100-mesh sieve for lactose, acesulfame potassium, and sodium carboxymethyl starch. Mix erdosteine and low-substituted hydroxypropyl cellulose evenly, pulverize them with a ball mill, pass through a 100-mesh sieve, add sodium carboxymethyl starch, dry-blend with a high-speed mixing granulator at a speed of 45 rpm, and mix for 10 minutes , after adding 25ml of absolute ethanol, carry out wet mixing, the speed is 30 rpm, mixing for 2 minutes, then wet mixing and cutting for 2 minutes, the prepared wet granules are transferred to a boiling dryer, and the te...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com