Preparation method and application of clove leaf total iridoid glycoside

A technology for total iridoid glycosides and cloves, which is applied in the field of preparation of total iridoid glycosides extracts in clove leaves, can solve problems such as difficulty in getting rid of inherent shortcomings, excessive dosage, complex components, etc., and achieves low cost , the effect of high desorption rate and large adsorption capacity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

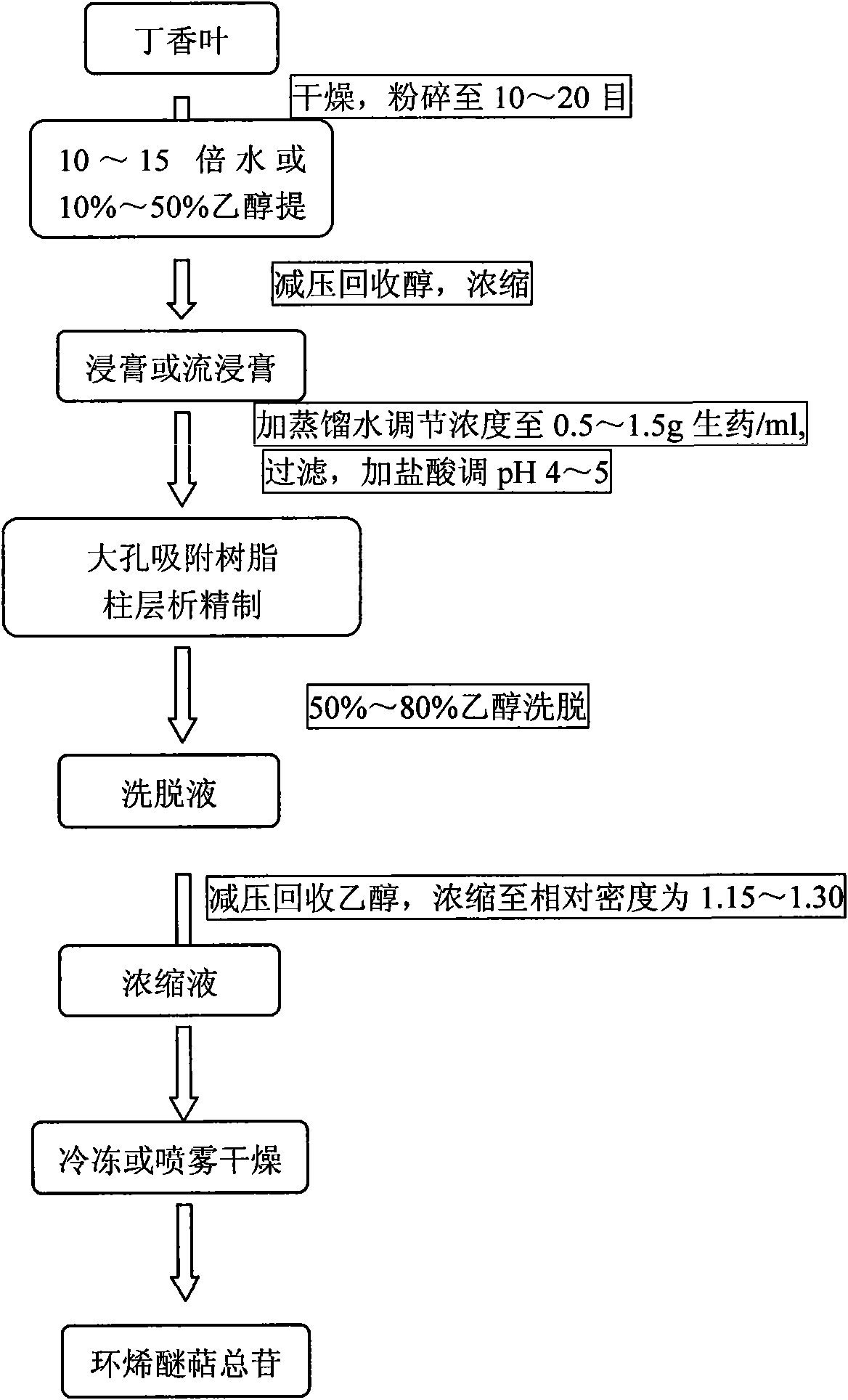

[0020] The preparation of embodiment 1 clove leaves total iridoid glycosides

[0021] see figure 1 , crush 1 kg of clove leaves to 10-20 meshes, add 12 times volume percentage of ethanol with a concentration of 30%, extract by percolation, collect the effluent after soaking for one week for the first time, collect the effluent after soaking for three days for the second time, filter, and combine The extract was concentrated to 0.5g crude drug / ml, added hydrochloric acid to adjust the pH value to 4, and passed through the D-101 macroporous adsorption resin chromatography column with a flow rate of 2BV / h, and the ratio of the loading sample solution to the dry resin was 1:5, the diameter-to-height ratio is 1:6, first wash the resin with 4BV of water, the elution flow rate is 2BV / h, discard the water eluent; then elute with 50% ethanol by volume, and elute The flow rate is 2BV / h, the eluent is depressurized to recover ethanol, concentrated to a relative density of 1.15 (measured...

Embodiment 2

[0022] The preparation of embodiment 2 clove leaves total iridoid glycosides

[0023] see figure 1 , in 2kg clove leaves crushed to 10-20 mesh, add 15 times the amount of water, heat and reflux extraction 3 times, 2h each time, filter, combine the extracts, concentrate to a concentration of 1.0g crude drug / ml, add hydrochloric acid after filtration Adjust the pH value to 4, and pass through the DM-301 macroporous adsorption resin chromatography column at a flow rate of 3BV / h. The ratio of the loading liquid to the dry resin is 1:8, and the ratio of diameter to height is 1:10. Wash the resin with 6BV of water, the elution flow rate is 4BV / h, discard the water eluent; then elute with methanol with a volume percentage concentration of 80%, the elution flow rate is 3BV / h, and the eluent is decompressed to recover methanol , concentrated to a relative density of 1.25 (measured at 50°C), and freeze-dried to obtain total iridoid glycosides of clove leaves. The measured total iridoi...

Embodiment 3

[0024] The preparation of embodiment 3 clove leaves total iridoid glycosides

[0025] see figure 1 , clove leaves 5kg moderately pulverized, add 8 times the amount of 10% ethanol, ultrasonically extract 3 times, 0.5h each time, filter, combine the extracts, recover ethanol under reduced pressure, add water to adjust the concentration to 1.5g crude drug / ml, add hydrochloric acid to adjust When the pH value reaches 4, it passes through the NKA-9 macroporous adsorption resin chromatography column. The ratio of the loading liquid to the dry resin is 1:9 according to the amount of solid matter and the ratio of diameter to height is 1:8. The resin is first washed with 4BV of water. The elution flow rate is 2BV / h, discard the water eluent; then elute with ethanol with a volume percentage concentration of 70%, the elution flow rate is 3BV / h, and the eluent is decompressed to recover ethanol, and concentrated to a relative density of 1.15 (measured at 50°C), and spray-dried to obtain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com