Method for preparing ellipsoid-shaped zinc oxide

A technology of zinc oxide and ellipsoid, which is applied in the field of metal oxide preparation, can solve the problems of unsuitability for large-scale industrial production, complex preparation process, and long process, and achieves suitable for large-scale production, good dispersion, and equipment simple effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] First prepare solution A: 1.19g Zn(NO 3 ) 2 .6H 2 O was dissolved in 80ml of deionized water, stirred at 500 rpm until completely dissolved; at the same time, prepared solution B: 5M concentrated ammonia solution; heated solution A to 90°C, and then added solution B dropwise to In solution A, until pH = 8, a white precipitate was obtained; the white precipitate was washed three times with deionized water and absolute ethanol, and finally vacuum-dried at 70° C. for 2 hours.

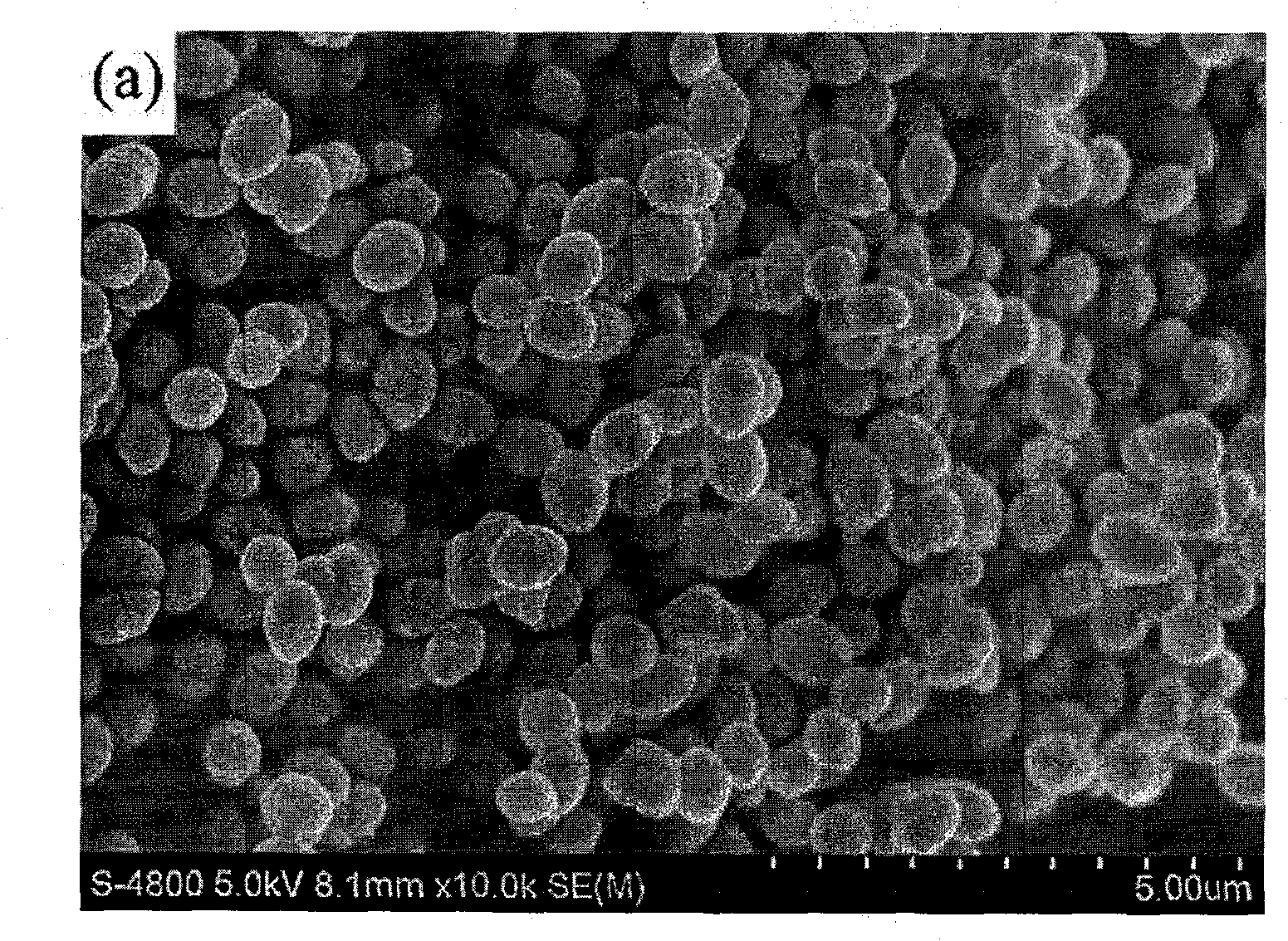

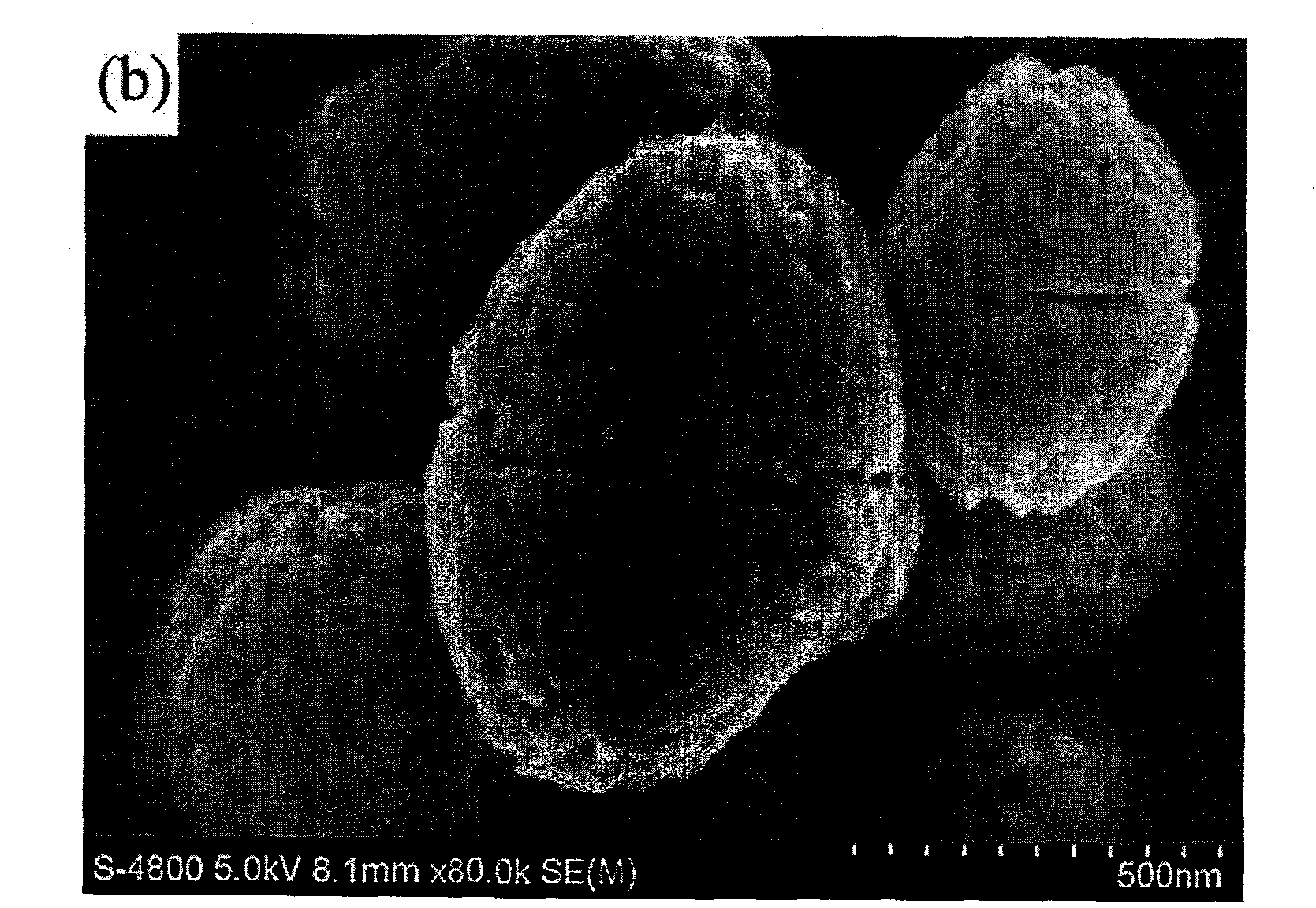

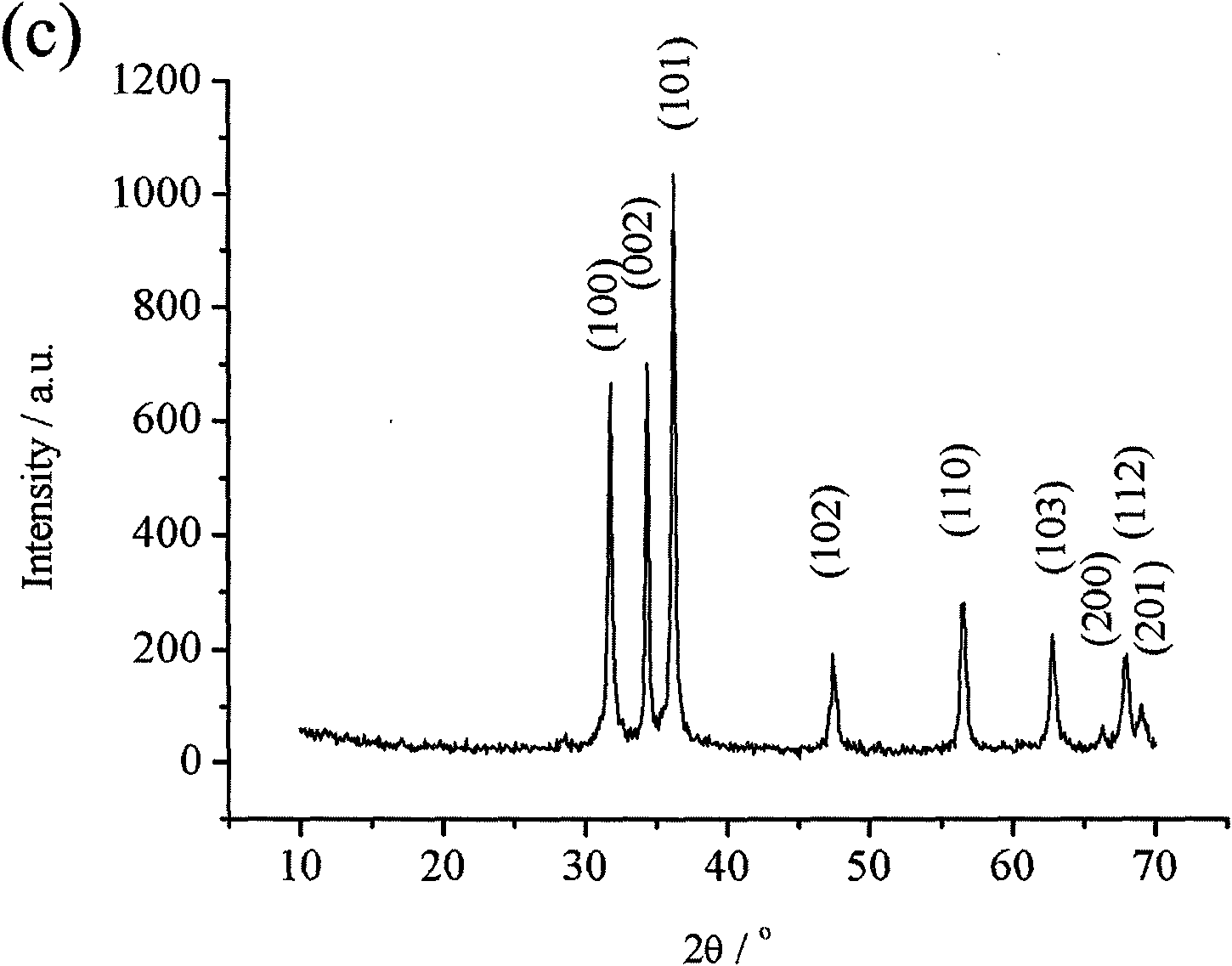

[0025] Fig. 1 is the photomicrograph and X-ray diffraction (XRD) pattern of the ellipsoidal zinc oxide prepared in this embodiment. It can be seen from Figure 1 (a) and (b) that the average size of the long axis of the zinc oxide ellipsoid is 800nm, and the average size of the short axis is 480nm, with good dispersion and no agglomeration. It can be seen from Figure 1(c) that all the diffraction peaks are those of ZnO, and no other impurity peaks appear, indicating that the synthesized ZnO has no...

Embodiment 2

[0027] First prepare solution A: 0.89g Zn(NO 3 ) 2 .6H 2 O was dissolved in 80ml of deionized water, stirred at 500 rpm until completely dissolved; at the same time, prepared solution B: 5M triethanolamine solution; heated solution A to 70°C, and then added solution B dropwise to In solution A, until pH = 7, a white precipitate was obtained; the white precipitate was washed three times with deionized water and absolute ethanol, and finally dried under vacuum at 60° C. for 2 hours.

[0028] figure 2 The morphology photo of the ellipsoidal zinc oxide prepared for this example, it can be seen from the figure that the average size of the long axis of the zinc oxide ellipsoid is 1410nm, the average size of the short axis is 1220nm, the dispersibility is good, and there is no agglomeration.

[0029] image 3 From the EDS energy spectrum of the ellipsoidal zinc oxide prepared for this example, it can be seen that there are no energy spectrum peaks of other elements except Zn and ...

Embodiment 3

[0031] A method for preparing ellipsoidal zinc oxide by a liquid phase method, comprising the steps of:

[0032] (1) Prepare solution A: dissolve a certain amount of zinc oxalate in deionized water, dissolve it under stirring at a speed of 30 rpm, until it is completely transparent, so that a solution A with a concentration of 0.001 is obtained;

[0033] (2) Prepare solution B: dissolve ammonia water in a certain amount of deionized water, and dissolve it under stirring at a speed of 30 rpm, so that a solution B with a concentration of 0.001M is obtained;

[0034] (3) Heat 0.001 M solution A to 50°C, and add 0.001 M solution B dropwise to solution A under stirring at a speed of 30 rpm until pH = 6, and a white precipitate is obtained;

[0035] (4) Wash the white precipitate obtained in step (3) with deionized water first, then with absolute ethanol, and repeat the washing twice; finally, dry under normal pressure at 60°C for 2 hours to prepare get the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com