Method for synthesizing graphite alkene by coordination assembly

A technology for synthesizing graphite and coordination, applied in the field of graphene synthesis, can solve the problems of complex equipment required for the reaction, poor production safety, harsh reaction conditions, etc., and achieve the effects of reducing synthesis cost, good conductivity and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

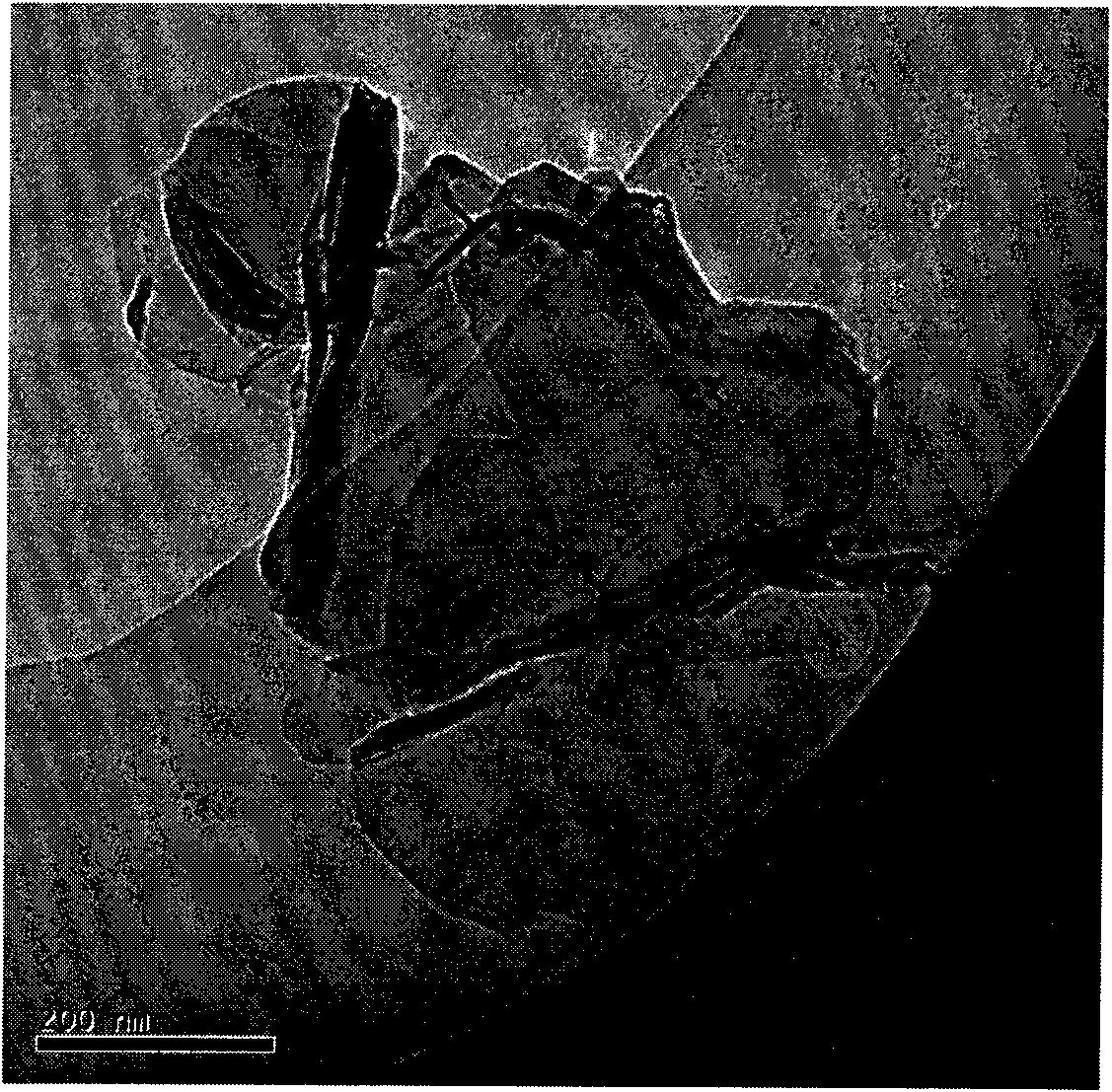

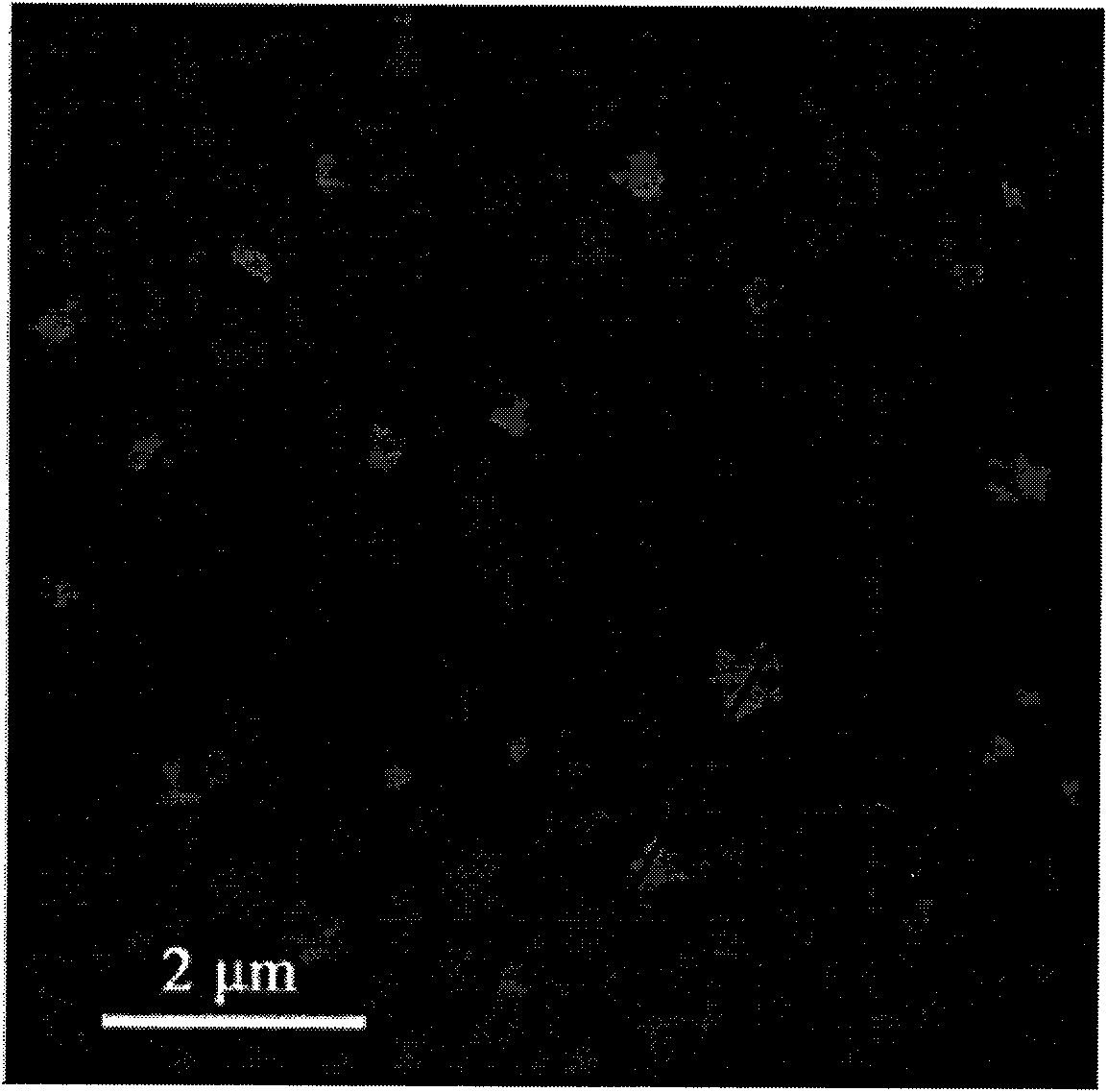

[0016] Specific embodiment one: the method for the coordination assembly synthesis graphene of this embodiment is completed by the following steps: one, adopt ultrasonic method, acid treatment method or alkali treatment method to carry out pretreatment to the carbon source with coordination group ( Activate the carbon source with the coordination group); 2. The carbon source with the coordination group is added in the solvent, the carbon source with the coordination group and the mass ratio of the solvent are 1: 2~100, then at 120 Heat treatment at ℃ for 2 to 8 hours, then add the catalyst at a temperature of 40 to 90 degrees C and a stirring speed of 100 to 350 r / min, and then stir for 4 to 24 hours. The mass ratio of the carbon source with the coordination group to the catalyst is 1: 0.05~2, the solvent is one of water, ethanol and ethylene glycol or a mixture of several of them; 3. Coordination assembly: use ultrasonic method, hydrothermal method or microwave method to proce...

specific Embodiment approach 2

[0018] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is that the carbon source with a coordination group described in step 1 is an anion-cation exchange resin with a coordination group, a macropore with a coordination group Resin, chelating resin with coordination group or high molecular polymer with coordination group. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0019] Specific embodiment three: the difference between this embodiment and specific embodiment two is: the anion-cation exchange resin with a coordination group is an acrylic weakly basic anion exchange resin with a coordination group, and has a coordination group Styrene-based strongly basic anion exchange resins, amphoteric ion-exchange resins with coordination groups, or acrylic cation-exchange resins with coordination groups. Other steps and parameters are the same as in the second embodiment.

[0020] Styrene-based strongly basic anion-exchange resins with coordinating groups such as D201×7 styrene-based strongly basic anion-exchange resins produced by Langfang Nanda Resin Co., Ltd.; acrylic acid-based weakly basic anion-exchange resins with coordinating groups Resin such as the D311 macroporous weakly basic acrylic acid series anion exchange resin produced by Wandong Chemical Co., Ltd., Tianchang City, Anhui Province; the amphoteric ion exchange resin with a coordinati...

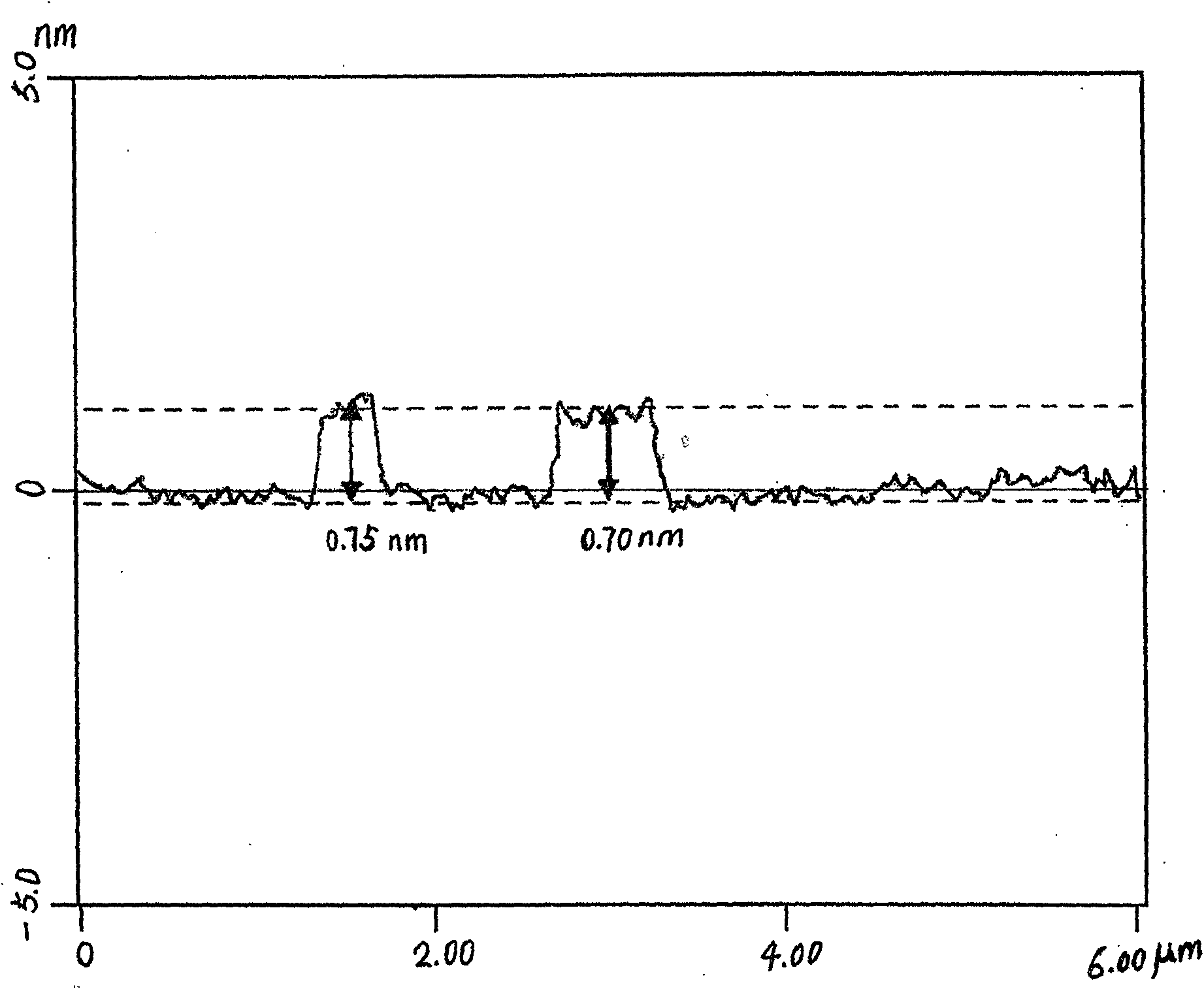

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com