Fluorescein sodium refining method

A technology of sodium fluorescein and a refining method, which is applied in the field of preparing pharmaceutical-grade high-purity sodium fluorescein, and can solve the problems of high cost, cumbersome, and many process steps

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

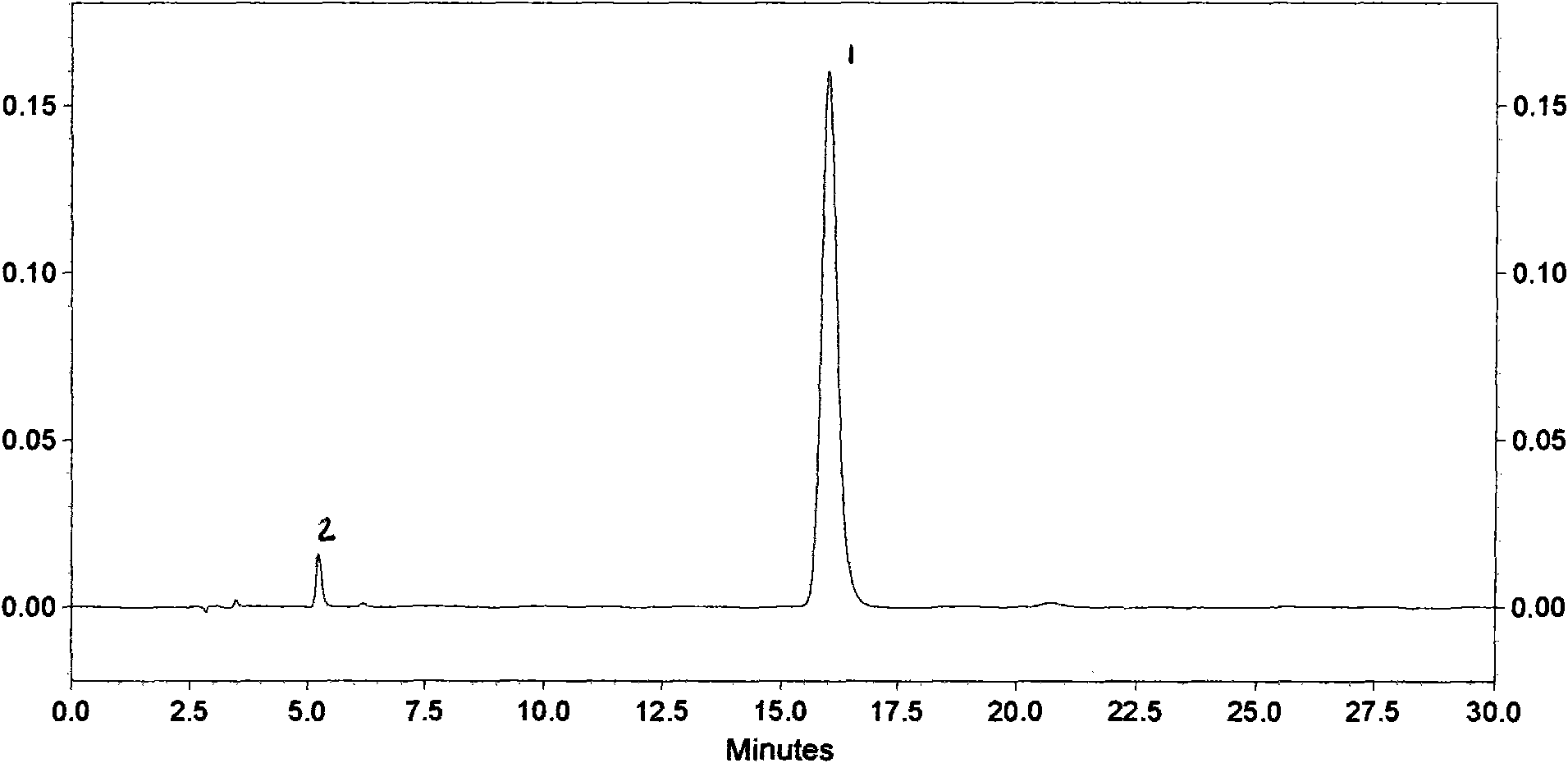

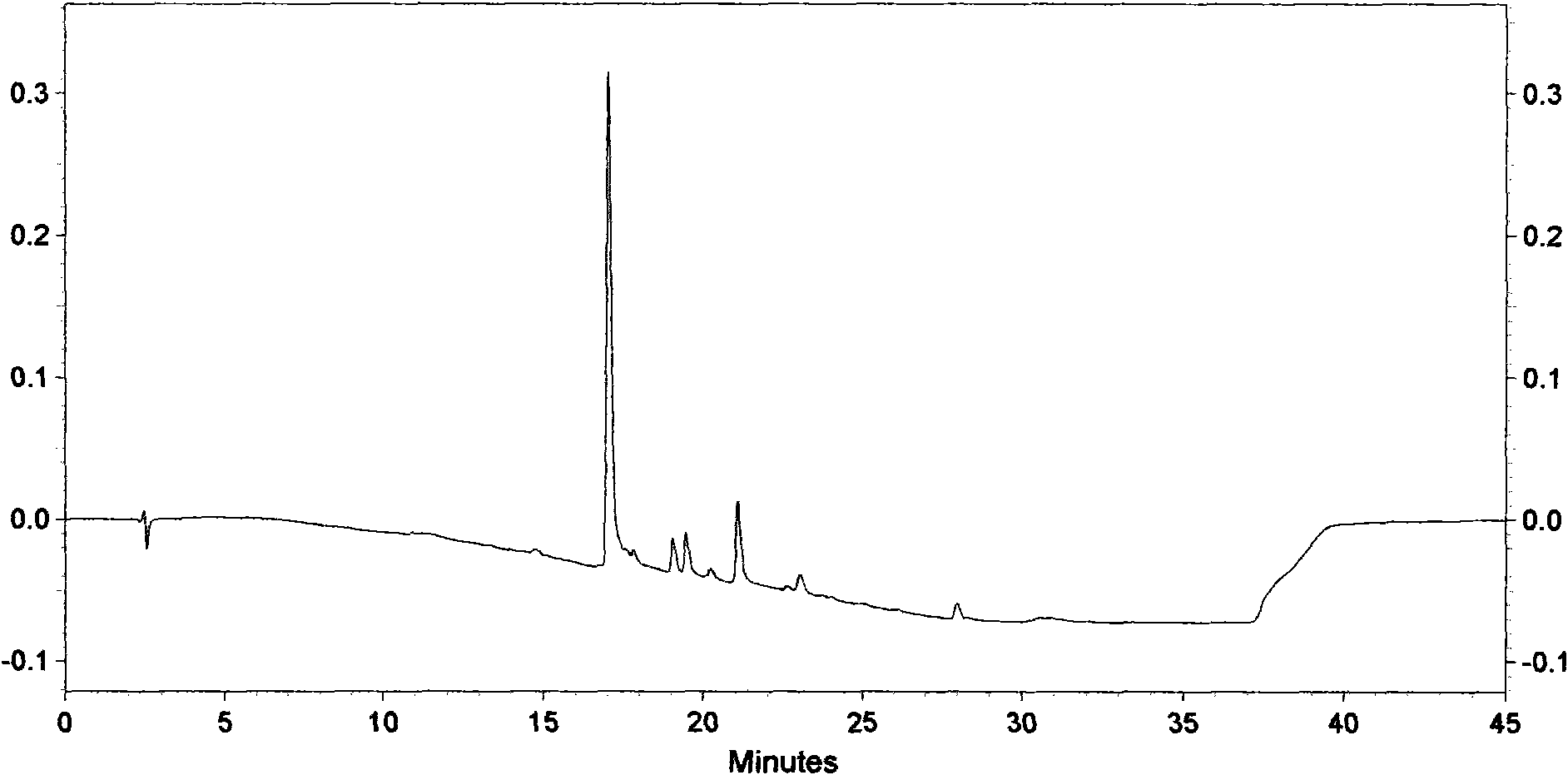

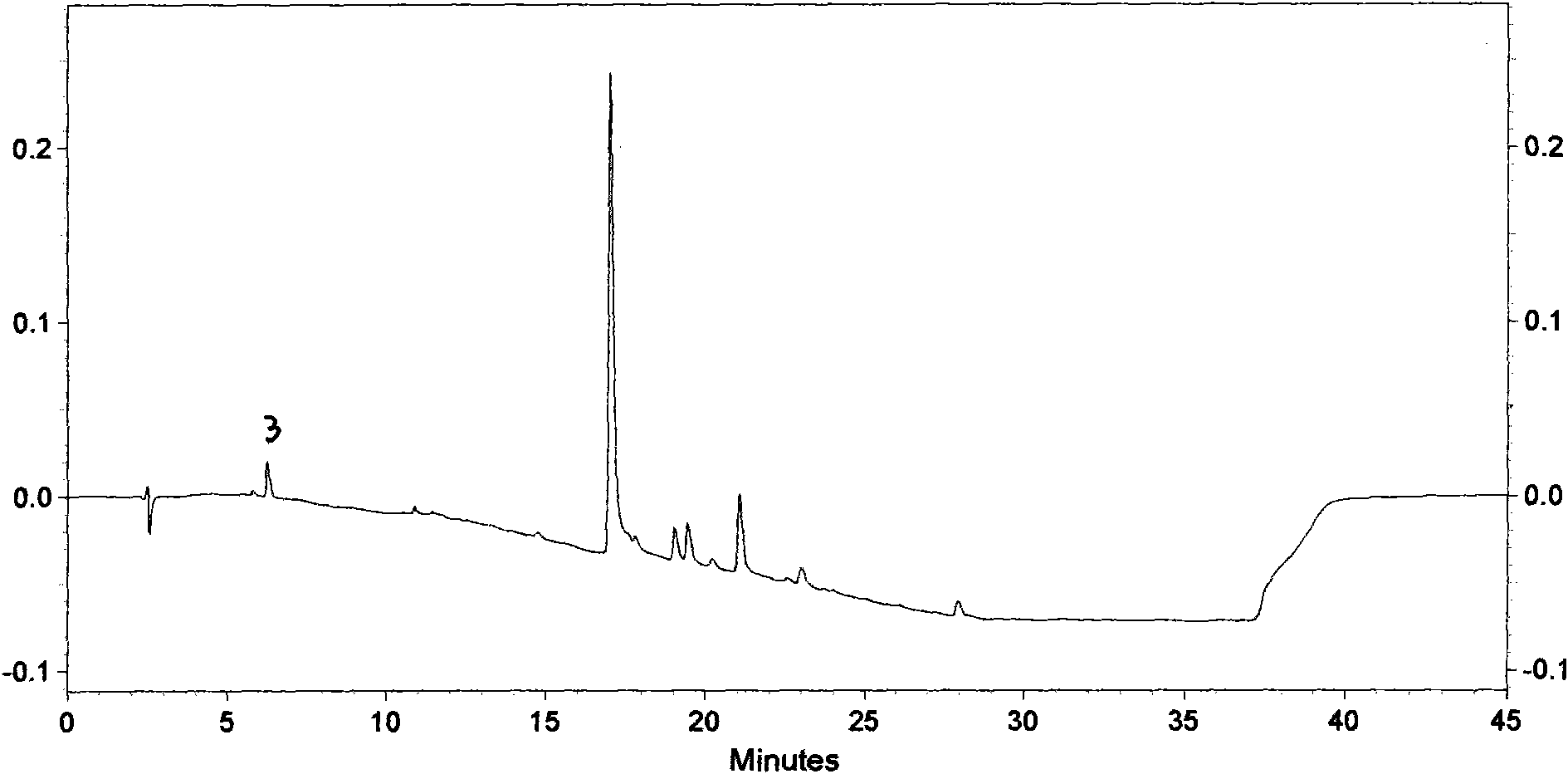

[0031] Take by weighing 100g of sodium fluorescein, (sodium fluorescein is provided by Tianjin Reagent No. 1 Factory, and the weight content is 95.0% (see attached figure 1 ), analyzed by HPLC (see attached Figure 2-5 , the impurity content is 7.1%,) add 100% ethanol 500ml, heat and reflux to dissolve, add the gac of 5g, filter after continuing to reflux for 15 minutes, get the hydrochloric acid (36.5%) that adds 56ml to the filtrate, stir, and make it cool down Let stand at room temperature for 18 hours, filter, wash the filter cake with 200ml of methanol and then wash with purified water until the chloride ions meet the requirements, put the fluorescein in 200ml of water, add sodium hydroxide solution (concentration 40%) to adjust the pH to 8.7 , the solution was concentrated to a thick thing, and dried at 105°C to obtain 75g of sodium fluorescein, the content of which was determined by high performance liquid chromatography to be 99.8% (see appendix Figure 6 ), the refin...

Embodiment 2

[0033]Weigh 100 g of sodium fluorescein (the same raw material as in Example 1), add 250 ml of 50% ethanol, heat and reflux to dissolve, add 10 g of activated carbon, continue to reflux for 30 minutes and filter, and add 56 ml of hydrochloric acid (36.5% ), stirred, and allowed to cool down to room temperature, placed for 16 hours, filtered, washed with purified water after the filter cake was washed with acetone until the chloride ion met the requirements, the fluorescein was placed in 200ml of water, and sodium hydroxide solution (concentration 40%) to adjust the pH to 8.8, the solution was concentrated to a thick substance, and dried at 105°C to obtain 70g of sodium fluorescein, the content of which was measured by high performance liquid chromatography was 99.7%, and the refined yield was 70%. 0.18%, 10% solution 600nm absorbance 0.379.

Embodiment 3

[0035] Weigh 100 g of fluorescein sodium, add 200 ml of water (same as the raw material of Example 1), stir and dissolve, add 10 g of activated carbon, heat and reflux for 30 minutes and filter, take the filtrate and add dropwise 56 ml of hydrochloric acid (36.5%), stir, and make It was cooled to room temperature, left for 20 hours, filtered, the filter cake was washed with ethanol and then washed with purified water until the chloride ion met the requirements, the fluorescein was placed in 150ml of water, and sodium hydroxide solution (concentration 40%) was added to adjust the pH to 8.75, the solution was concentrated to a thick substance, dried at 105°C to obtain 60g of sodium fluorescein, the content determined by high performance liquid chromatography was 99.6%, the refined yield was 60%, the impurity content was 0.32%, and the 10% solution 600nm absorbance 0.495.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com