Resistive random access memory and manufacturing method thereof

A resistive memory, parylene technology, applied in the field of flexible electronics, can solve the problems of inability to defend against solvents, limit storage density, inability to miniaturize and high-density applications, and achieve good process compatibility and improve storage density. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0027] Below in conjunction with accompanying drawing and specific embodiment the present invention is described in further detail:

[0028] Referring to Figure 1, the preparation of the resistive memory of the present invention is specifically as follows:

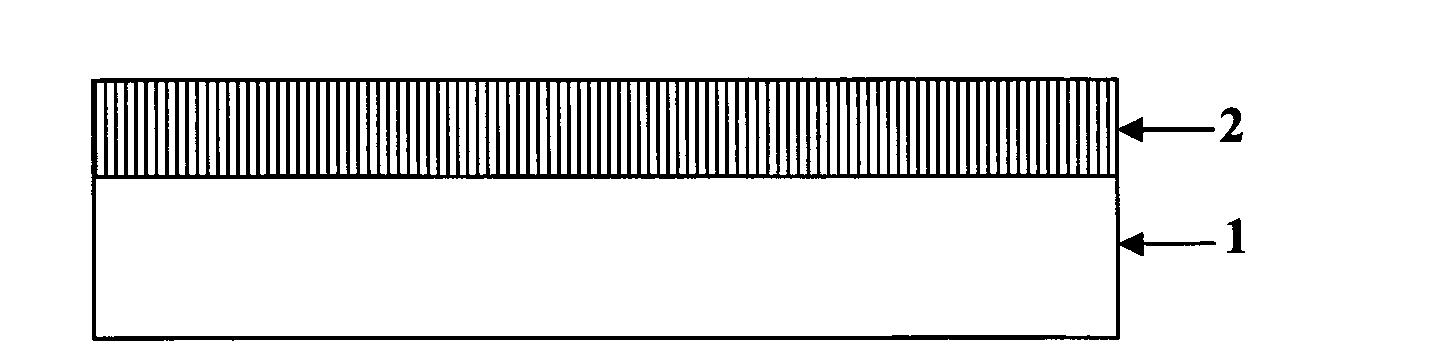

[0029] 1) On the silicon substrate 1, tungsten metal in a conventional CMOS process is used as the lower electrode 2; the lower electrode adopts a physical vapor deposition (PVD) method, and the tungsten electrode can be patterned by standard photolithography and wet etching techniques, Figure 1(a);

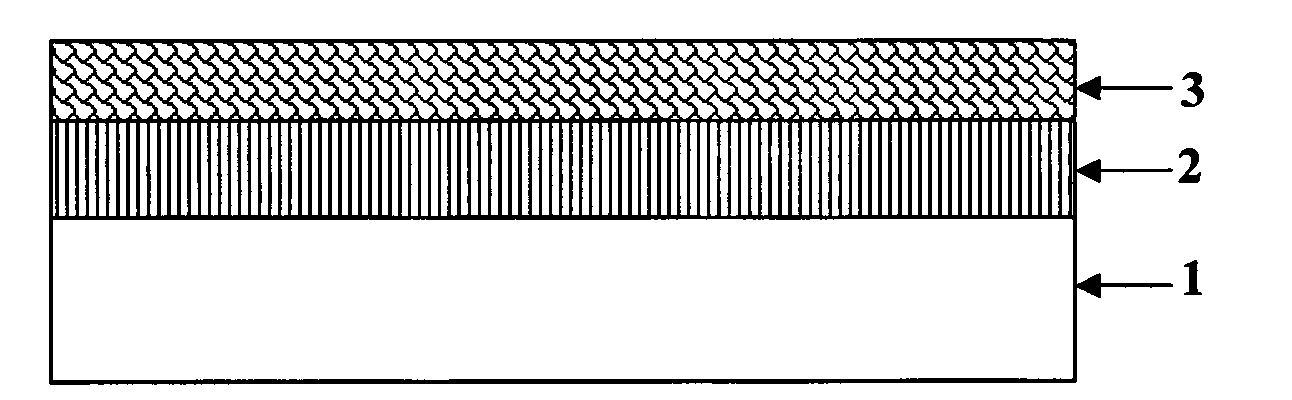

[0030] 2) Use polymer chemical vapor deposition (Polymer CVD) technology to deposit parylene-C type (Parylene-C film 3, with a thickness of 50-150nm, as shown in Figure 1(b); CVD equipment, process selection equipment standard parameters, deposition rate between 1nm / min and 10nm / min;

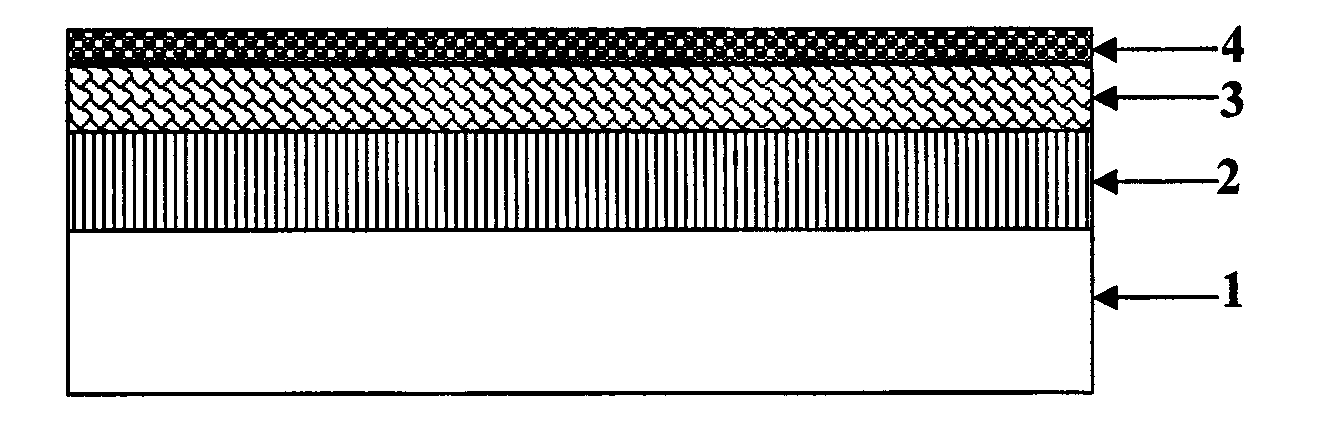

[0031] 3) Utilize the physical vapor deposition method to deposit the gold nanolayer 4 of 6-20nm, as shown in Figure 1 (c);

[0032] 4) By ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com