LiFePO4/C preparation method

A technology of hydrothermal method and precipitant, which is applied in the direction of electrode manufacturing, electrical components, battery electrodes, etc., can solve problems such as the increase of ferric iron content in lithium ferrous phosphate, the increase of industrial production costs, and the increase of lithium recovery process. Achieve excellent electrochemical performance, cost reduction, uniform particle size distribution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

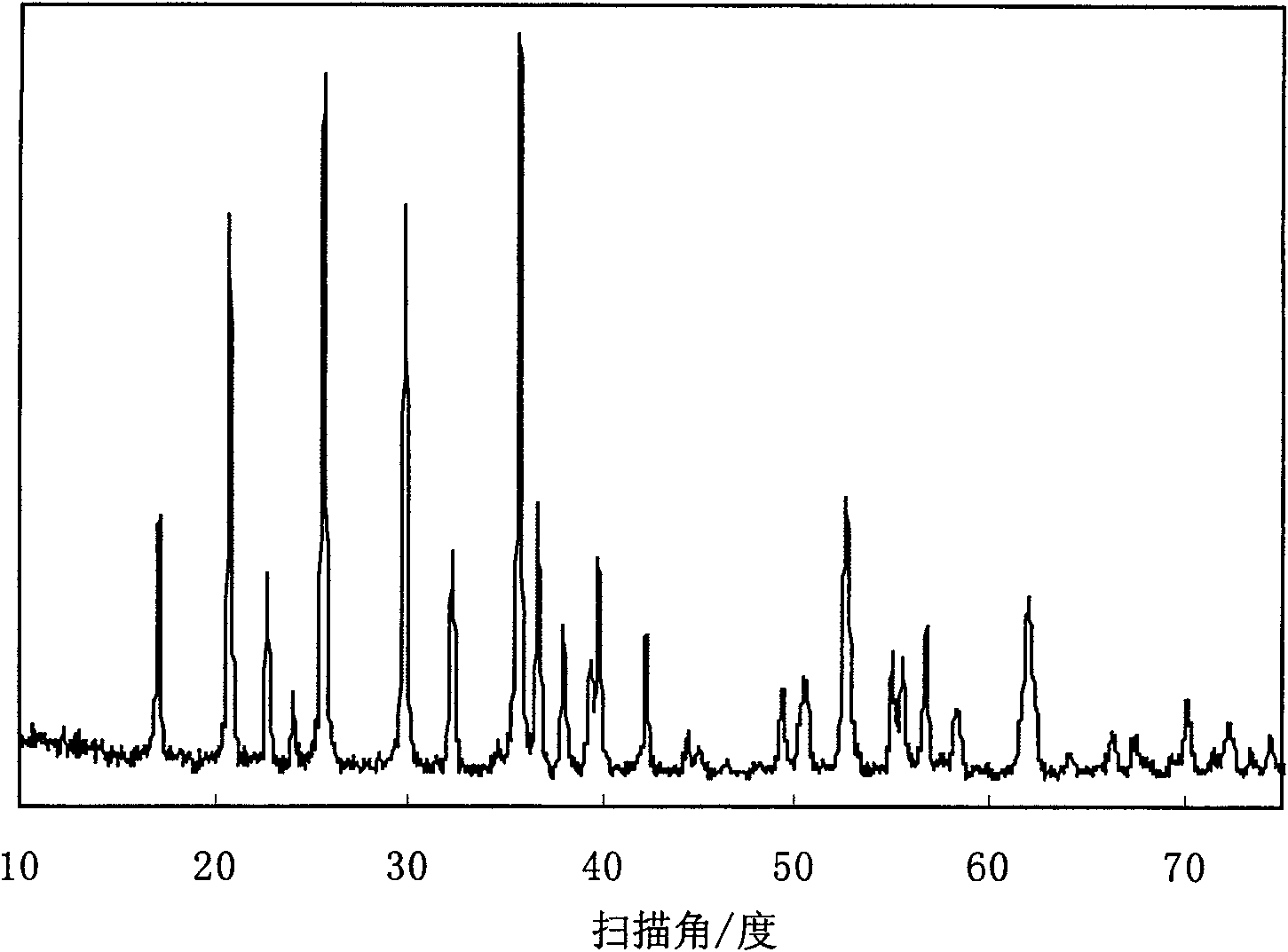

[0033] In this example, LiFePO 4 The processing steps of the / C preparation method are as follows:

[0034] (1) Synthesis of LiFePO by hydrothermal method 4

[0035] The raw materials and their supplies are:

[0036] Iron 0.2mol (FeSO 4 ·7H 2 O 55.61 grams), phosphorus 0.2mol (85% H 3 PO 4 23.0586 grams), lithium 0.18mol (LiOH·H 2 O7.5528 grams), ascorbic acid 0.0091mol (1.6 grams), urea 0.09mol (5.406 grams), nanoscale LiFePO 4 0.12 grams;

[0037] The operation is:

[0038] FeSO 4 ·7H 2 O and ascorbic acid were added to 300 mL deionized water to prepare an iron source-antioxidant solution, and LiOH·H 2 O was added with 200mL deionized water to prepare a lithium source solution, and the H 3 PO4 Add 150mL of deionized water to make a phosphorus source solution, then drop the phosphorus source solution into the lithium source solution at room temperature (26°C) and normal pressure under stirring, and at the same time, add urea to the lithium source solution to act ...

Embodiment 2

[0044] In this example, LiFePO 4 The processing steps of the / C preparation method are as follows:

[0045] (1) Synthesis of LiFePO by hydrothermal method 4

[0046] The raw materials and their supplies are the same as in Example 1.

[0047] The operation is basically the same as that of Example 1, except that: when the temperature of the autoclave reaches 210° C., the timer is started, and the temperature is kept at 210° C. for 2 hours.

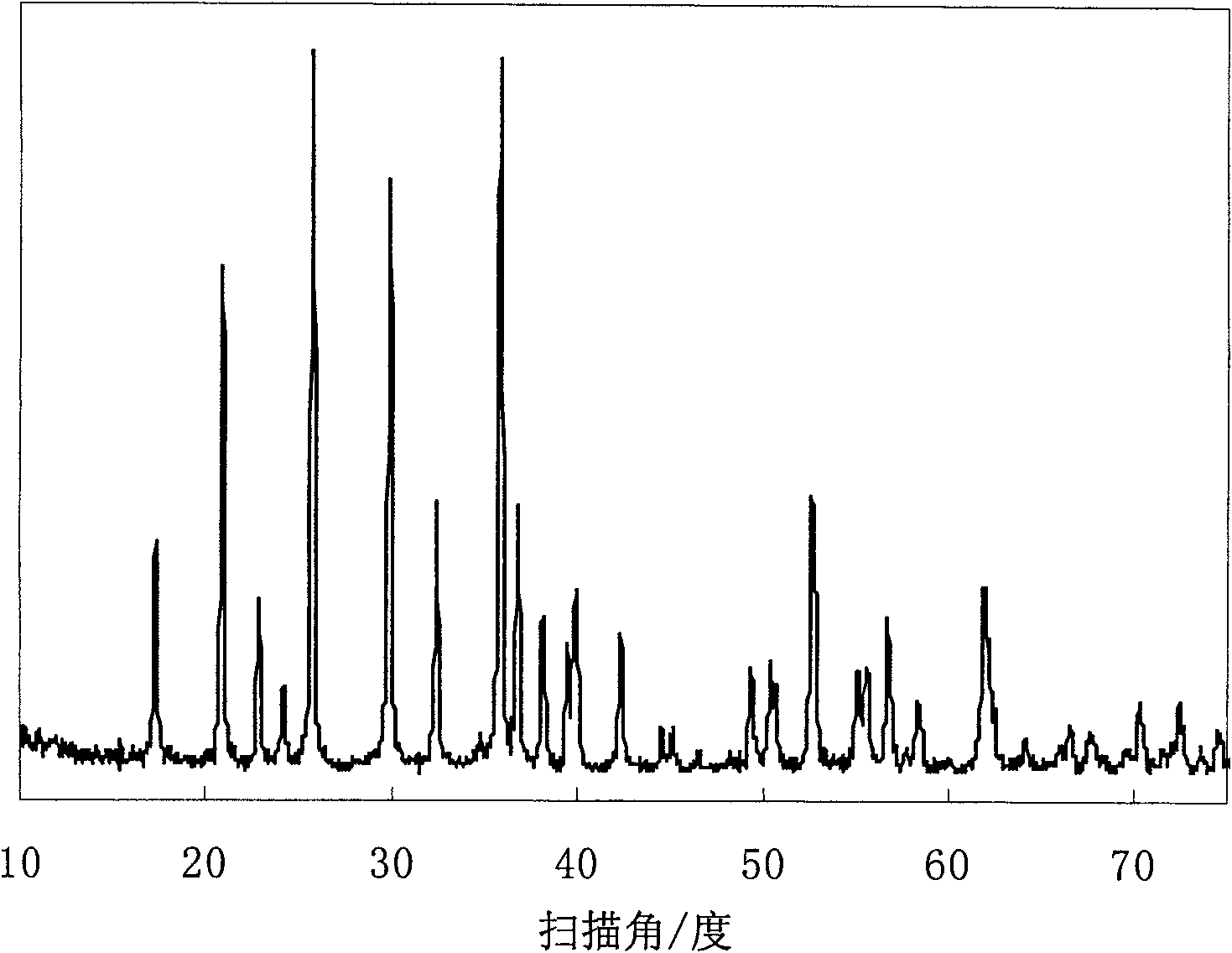

[0048] (2) Carbon doping and calcination

[0049] The LiFePO prepared in step (1) 4 Weigh 20 grams, add 6 grams of glucose, and use a ball mill to grind LiFePO 4 Mix well with glucose, then LiFePO 4 The mixture with glucose was put into a tube furnace and heated to 500°C under the protection of nitrogen for 40 hours. After the heat preservation was completed, it was cooled to room temperature with the furnace to obtain LiFePO 4 / C, its X-ray diffraction pattern is shown in figure 2 , with an average particle size of 1.0 microns and ...

Embodiment 3

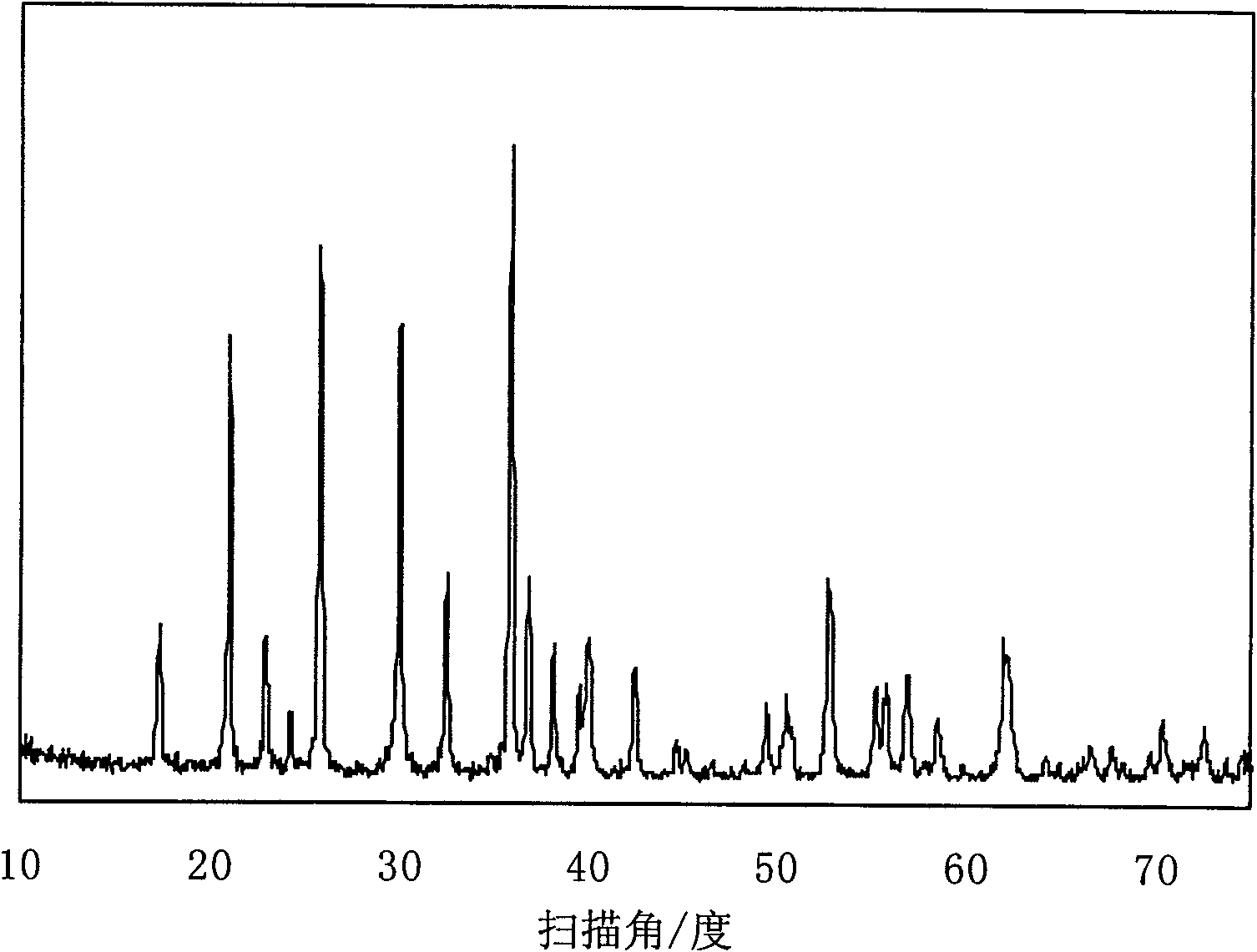

[0052] In this example, LiFePO 4 The processing steps of the / C preparation method are as follows:

[0053] (1) Synthesis of LiFePO by hydrothermal method 4

[0054] The raw materials and their supplies are:

[0055] Iron 0.2mol (FeCl 2 25.349 grams), phosphorus 0.2mol (NH 4 h 2 PO 4 23.005 g), lithium 0.19 mol (LiAc.2H 2 O19.3838 grams), cetyltrimethylammonium bromide 0.004mol (1.456 grams), formamide 0.475mol (21.394 grams), nanoscale LiFePO 4 1.6 grams.

[0056] The operation is:

[0057] FeCl 2 and cetyltrimethylammonium bromide plus 500mL deionized water to prepare iron source-antioxidant solution, LiAc.2H 2 O was added with 300mL deionized water to prepare a lithium source solution, and the NH 4 h 2 PO 4 Add 300mL of deionized water to prepare a phosphorus source solution, then drop the phosphorus source solution into the lithium source solution at room temperature (25°C) and normal pressure under stirring, and at the same time, add formamide to the lithium...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com