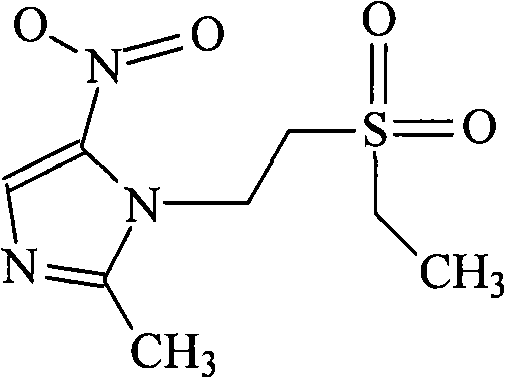

Tinidazole liposome injection and preparation method thereof

A technology for tinidazole lipid and injection, applied in the field of medicine, can solve problems such as instability of tinidazole injection, and achieve the effects of reducing drug side effects, avoiding crystallization and ensuring product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

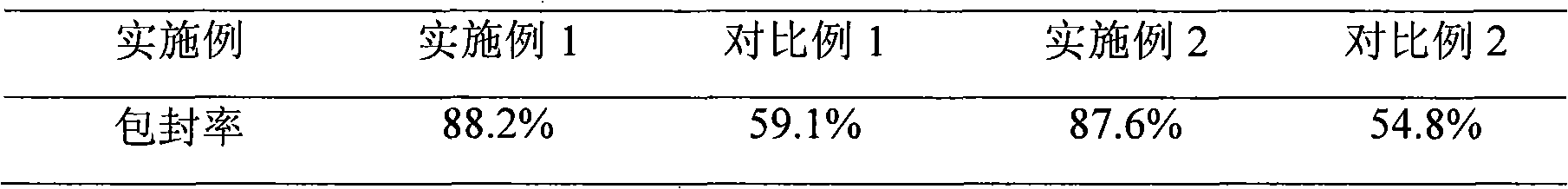

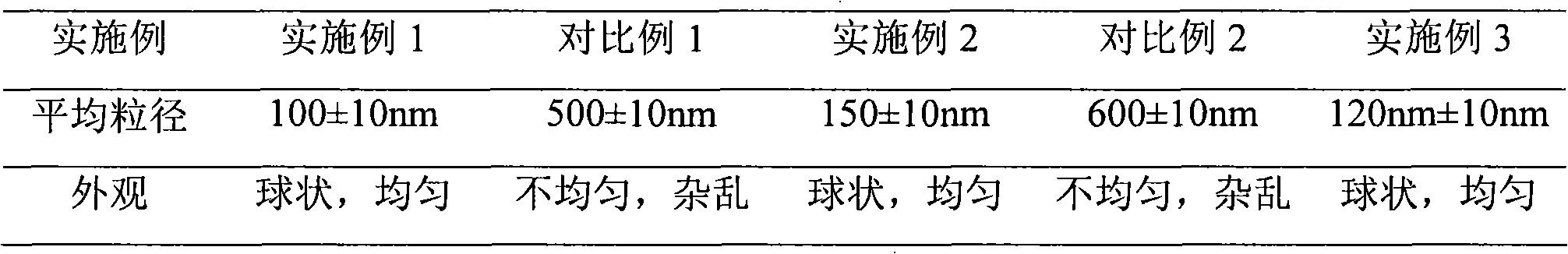

Embodiment 1

[0034] Example 1 Preparation of tinidazole liposomes

[0035] Prescription (100 bottles): Tinidazole 20g

[0036] Hydrogenated Soy Lecithin 200g

[0037] Cholesterol 10g

[0038] Polysorbate 80 40g

[0039] Sodium deoxycholate 20g

[0041] Preparation Process

[0042] (1) 200g hydrogenated soybean lecithin, 10g cholesterol, 20g sodium deoxycholate and 40g polysorbate 80 are dissolved in the ethanol of 1000ml;

[0043] (2) tinidazole 20g and sodium chloride 90g are dissolved in the phosphoric acid-disodium hydrogen phosphate buffer solution of 8000mlpH value 5.0;

[0044] (3) Mix the two and stir to form a W / O emulsion, heat and stir to evaporate, when the mixture reaches a viscous state, add 2000ml of phosphate buffer with a pH value of 5.0, continue to heat and stir to evaporate to remove residual ethanol, and ultrasonic for 30min , transferred to a high-speed homogeneous mix...

Embodiment 2

[0056] Example 2 Preparation of tinidazole liposomes

[0057] Prescription (100 bottles): Tinidazole 40g

[0058] Dioleoyl Phosphatidylcholine 160g

[0059] Cholesterol 100g

[0060] Polysorbate 80 200g

[0061] Sodium deoxycholate 50g

[0062] Mannitol 1000g

[0063] Preparation Process

[0064] (1) 160g dioleoylphosphatidylcholine, 100g cholesterol, 50g sodium deoxycholate and 200g polysorbate 80 are dissolved in 2000ml of tert-butyl alcohol;

[0065] (2) 40 g of tinidazole and 1000 g of mannitol are dissolved in 16 L of acetic acid-sodium acetate buffer solution with a pH value of 4.6;

[0066] (3) Mix the two, stir to form a W / O emulsion, heat and stir to evaporate, when the mixture reaches a viscous state, add 4000ml of acetate buffer solution with a pH value of 4.6, continue to heat and stir to evaporate to remove residual tert-butanol , sonicated for 30 minutes, transferred to a high-speed homog...

Embodiment 3

[0078] Example 3 Preparation of tinidazole liposomes

[0079] Prescription (100 bottles): Tinidazole 80g

[0080] Soy Phosphatidylglycerol 600g

[0081] Cholesterol 60g

[0082] Polysorbate 80 300g

[0083] Sodium deoxycholate 100g

[0084] Glycerin 3000g

[0085] Preparation Process

[0086] (1) 600g soybean phosphatidylglycerol, 60g cholesterol, 100g sodium deoxycholate and 300g polysorbate 80 are dissolved in 4000ml of isopropanol;

[0087] (2) 80 g of tinidazole and 3000 g of glycerin were dissolved in 18 L of citric acid-sodium citrate buffer solution with a pH value of 6.2;

[0088] (3) Mix the two, stir to form a W / O emulsion, heat and stir to evaporate, when the mixture reaches a viscous state, add 2000ml of citrate buffer with a pH value of 6.2, continue to heat and stir to evaporate to remove residual isopropyl Alcohol, sonicated for 30 minutes, transferred to a high-speed homogeneous mixer, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com