Constitutive acidic incision cellulase high-yield strain

An endo-cellulase and high-yielding strain technology, applied in the field of microbiology, can solve the problems of long fermentation period, large molecular weight, low enzyme activity, etc., and achieve the effects of good pH stability, short enzyme production period and high catalytic ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] This embodiment illustrates the screening process of Bacillus subtilis LC:

[0039] Wherein the medium used for screening is:

[0040] Liquid medium formula (g / L): 3.0KH 2 PO 4 , 0.3MgSO 4 ·7H 2 O, 5.0 sucrose, 15.0 peptone, 30mL / L corn steep liquor.

[0041] Fermentation basal medium (g / L): 3.0KH 2 PO 4 , 0.3MgSO 4 ·7H 2 O, 5.0 yeast extract, 15.0 peptone.

[0042] Induction medium (g / L): Add 5g / L CMC-Na on the basis of the fermentation basal medium.

[0043] Congo red plate medium (g / L): 3.0KH 2 PO 4 , 0.3MgSO 4 ·7H 2 O, 5CMC-Na.

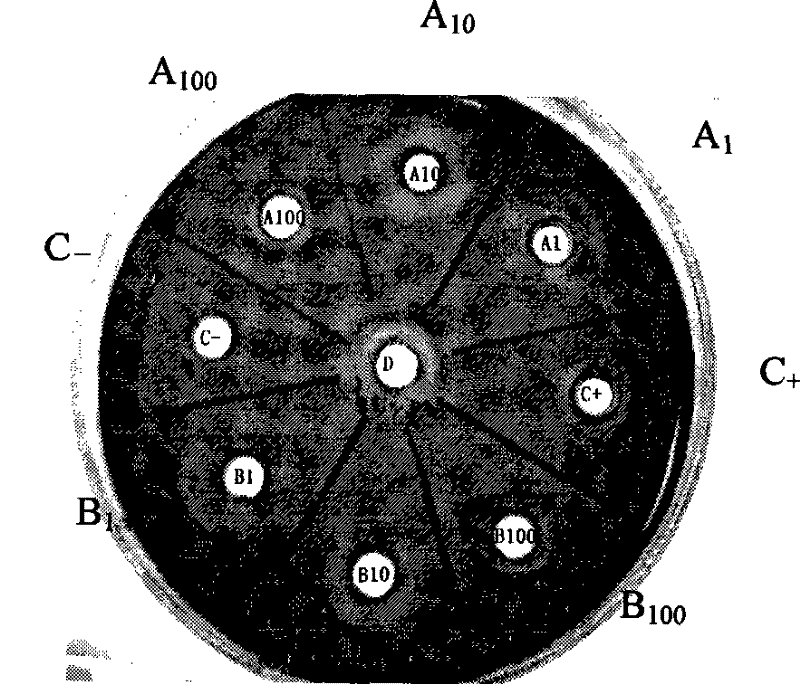

[0044] Take about 0.5 g of soil samples from the forest area of Nanjing, add them to the liquid medium for enrichment culture (30°C, 180r / min), culture for 5-7 days and then transfer, and transfer three times in the same medium. Properly dilute the bacterial solution after enrichment culture, and the dilution gradient is determined according to the turbidity of the culture solution (105-107 times). Take 100 μL of the dilut...

Embodiment 2

[0049] This example illustrates the extraction of acidic constitutive endocellulase LC from Bacillus subtilis LC.

[0050] 1. Cell culture:

[0051] Solid medium formula (g / L): 1.0KH 2 PO 4 , 0.5MgSO 4 ·7H 2 O, 5.0 yeast extract, 10.0 peptone, the pH of the solid medium is 7.0-7.5;

[0052] Liquid medium formula (g / L): 3.0KH 2 PO 4 , 0.3MgSO 4 ·7H 2 O, 5.0 sucrose, 15.0 peptone, 30mL / L corn steep liquor, the pH of the seed liquid medium is 7.0, and the optimal initial pH of the fermentation medium is 5-5.5.

[0053] Inoculate Bacillus subtilis LC on solid medium, culture at 37°C for 10-12 hours, then transfer to 50mL / 250mL liquid seed medium, cultivate at 37°C and 200r / min for 10-12h, and then transfer to 2% inoculum Connect with 50mL / 250mL liquid fermentation medium and cultivate for 36h at 37°C and 200r / min.

[0054] 2. Treatment of extracellular product crude enzyme solution:

[0055] Freeze and centrifuge the fermentation broth at a speed of 10000r / min for 10min...

Embodiment 3

[0079] This example illustrates the relevant properties of the acidic constitutive endocellulase LC extracted from Bacillus subtilis LC:

[0080] (1) Basic kinetic constant K m and the maximum reaction speed V max Determination of

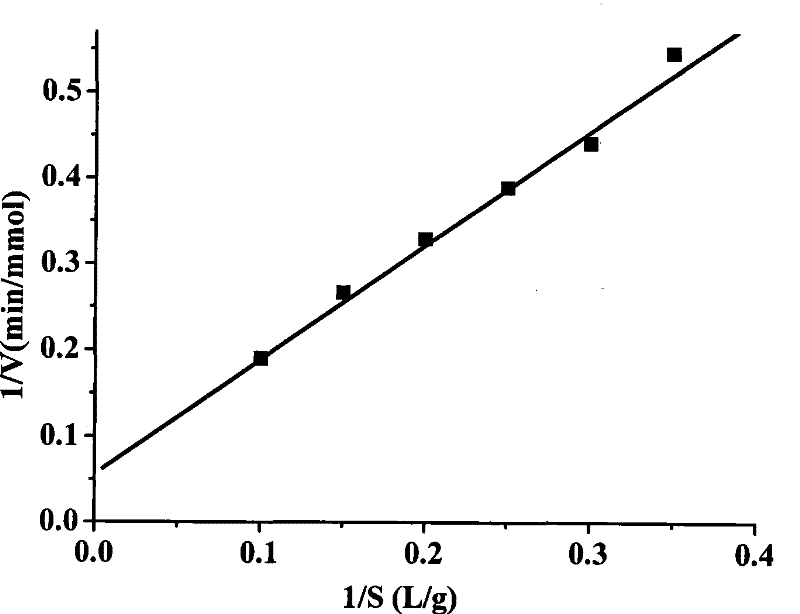

[0081] With different concentrations of CMC-Na as the substrate, under the conditions of the optimum catalytic temperature (65°C) and optimum pH (pH5.0), the enzymatic reaction rate was measured, and the K m value and V max , as attached image 3 Shown, where 1 / V=0.05607+1.32496×1 / S.

[0082] Michaelis constant K of endocellulase LC m 0.0423mg / mL, V max It is 135.85mg / min. It shows that the endocellulase LC has a stronger affinity to the substrate sodium carboxymethyl cellulose and has a strong catalytic ability.

[0083] (2) Enzymatic properties

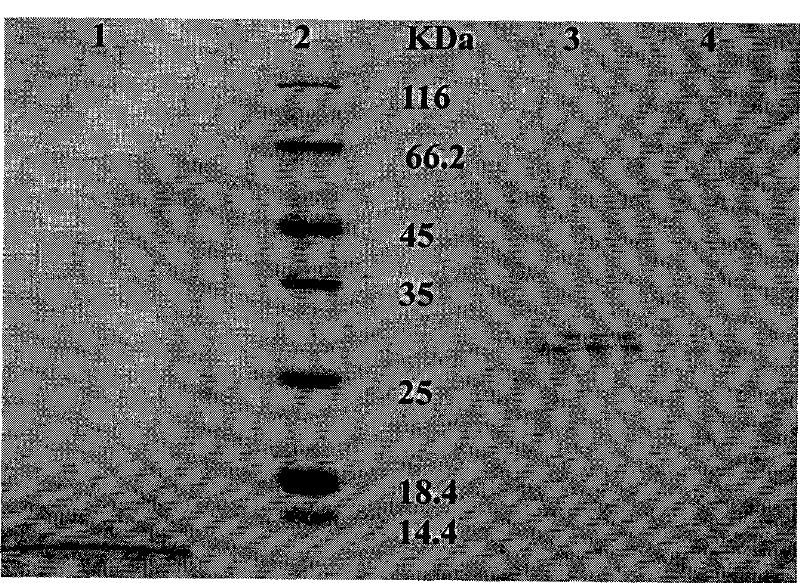

[0084] 1. Determination of molecular weight of enzyme protein

[0085] Determined by SDS-PAGE electrophoresis, the results are attached figure 2 . Gel scanning was performed with GEL-DOC2000...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com