Production method of high-nutrient hawthorn powder

A manufacturing method and technology of hawthorn powder, which are applied in food preparation, food forming, food preservation and other directions, can solve the problems of coarse hawthorn powder, high processing temperature, poor product solubility, etc. The effect of export and high utilization rate of raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

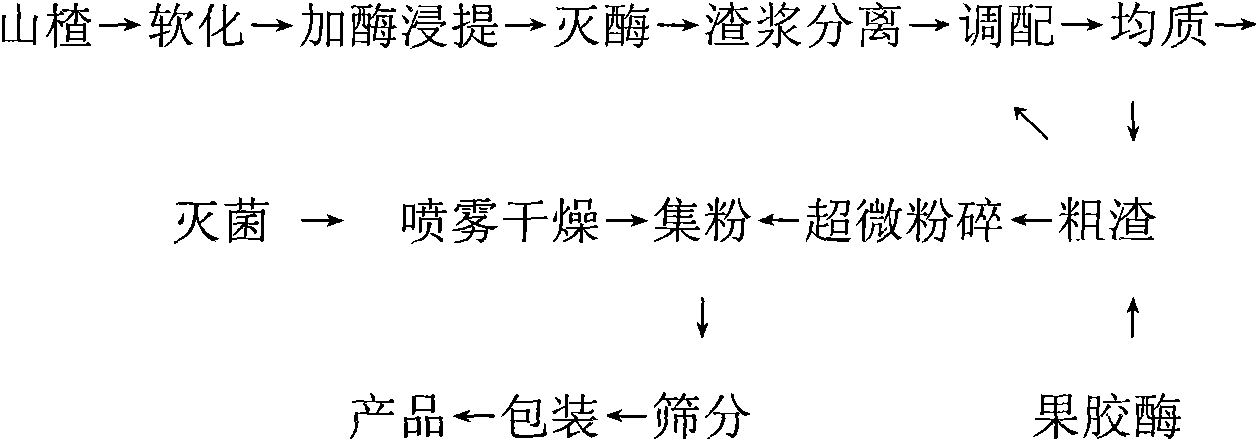

[0020] The manufacturing method of high-nutrition hawthorn powder is characterized by using fresh hawthorn as the main raw material, after softening, enzyme extraction, enzyme elimination, slurry separation, deployment, secondary treatment, homogenization, sterilization, spray drying, Powder collection, sieving, packaging, and product warehousing are processed to obtain a hawthorn powder product that retains the original color, aroma, and taste of the hawthorn and has good instant solubility.

[0021] Specific implementation steps: select fresh hawthorns with complete fruit shape, moderate maturity, dark red color, plump body, and fruit diameter not less than 20 mm as raw materials, and remove injured, rotten, and shriveled fruits. Rinse the hawthorn with pressurized running water, wash off the soil and sundries attached to the surface, drain off the surface water, and weigh 102kg. Use a roller crusher to crush the fruit. It is better if the fruit is broken into a flat shape a...

Embodiment 2

[0023] The production process and method are the same as in Example 1, and the process conditions are changed to: pump 300 kg of hawthorn pulp into a sandwich pot with a stirrer, add 24 kg of isomaltooligosaccharides and 36 kg of resistant starch, and add 15 kg of trehalose at the same time, and stir evenly . Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 13.0MPa. Air inlet temperature: 175°C, exhaust air temperature: 85°C, 38kg of finished product is obtained after drying, and the moisture content of the material is 5%.

Embodiment 3

[0025] The production process and method are the same as in Example 1, and the process conditions are changed to: pump 300 kg of hawthorn pulp into a sandwich pot with a stirrer, add 36 kg of isomaltooligosaccharides and 54 kg of resistant starch, and add 15 kg of trehalose at the same time, and stir evenly . Use a spray dryer to dry, and the condition is: the pressure of the high pressure pump is controlled at 12.5MPa. Air inlet temperature: 180°C, exhaust air temperature: 88°C, 41kg of finished product is obtained after drying, and the moisture content of the material is 5%.

[0026] This product has fresh color, good instant solubility, rich nutritional components, and good taste. The high-quality powdered food is convenient for long-distance transportation. The invention provides a high-quality powdered food raw material for improving people's physical fitness, which can be widely used in food and Health products and other industries.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com