Method and device for producing thiophene and derivative thereof in direct-cooled mode

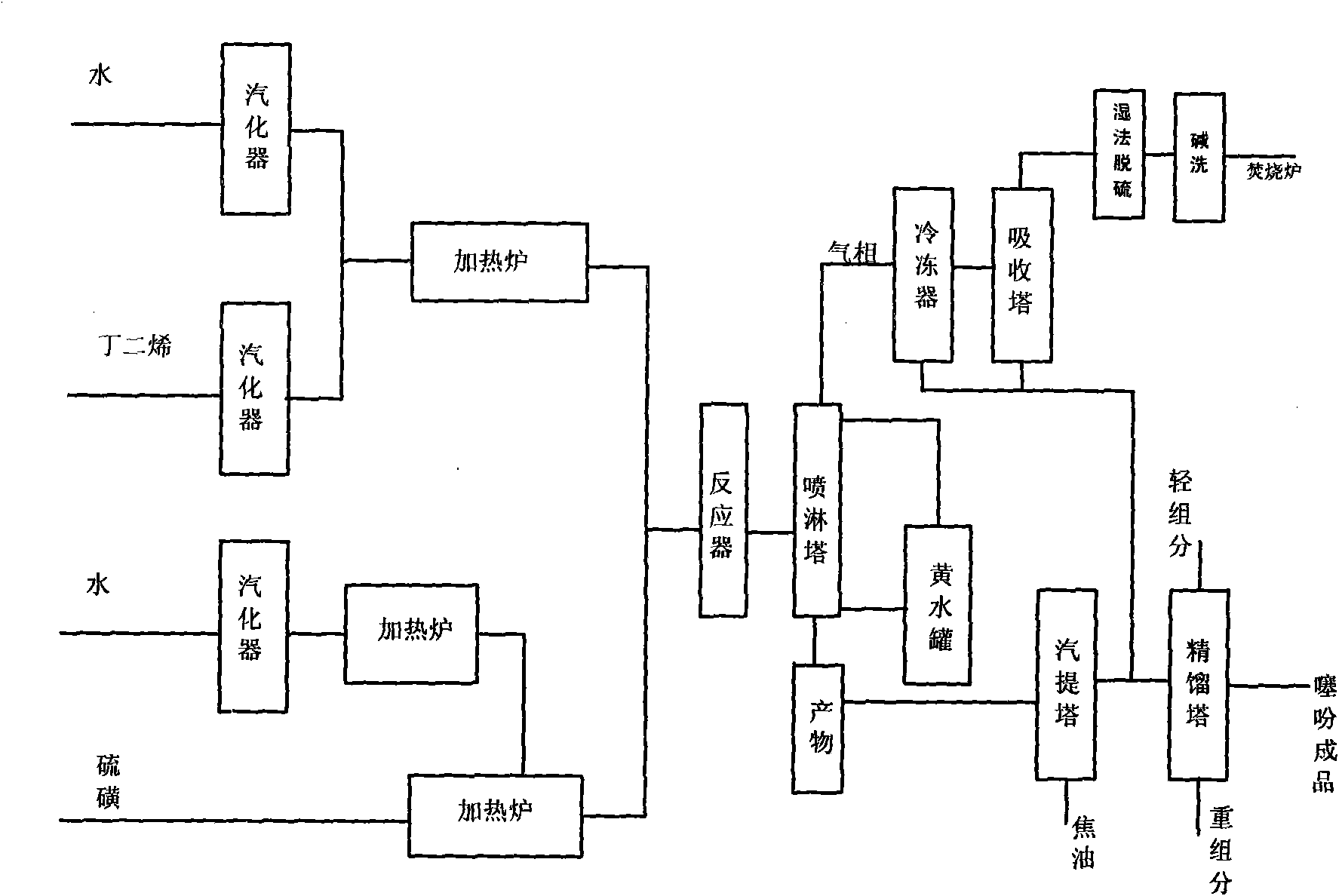

A production method and technology for thiophene are applied in the field of production methods and devices implementing the method, and can solve the problems of reactor coking blockage, thiophene loss, and high energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] The production of embodiment 1 thiophene

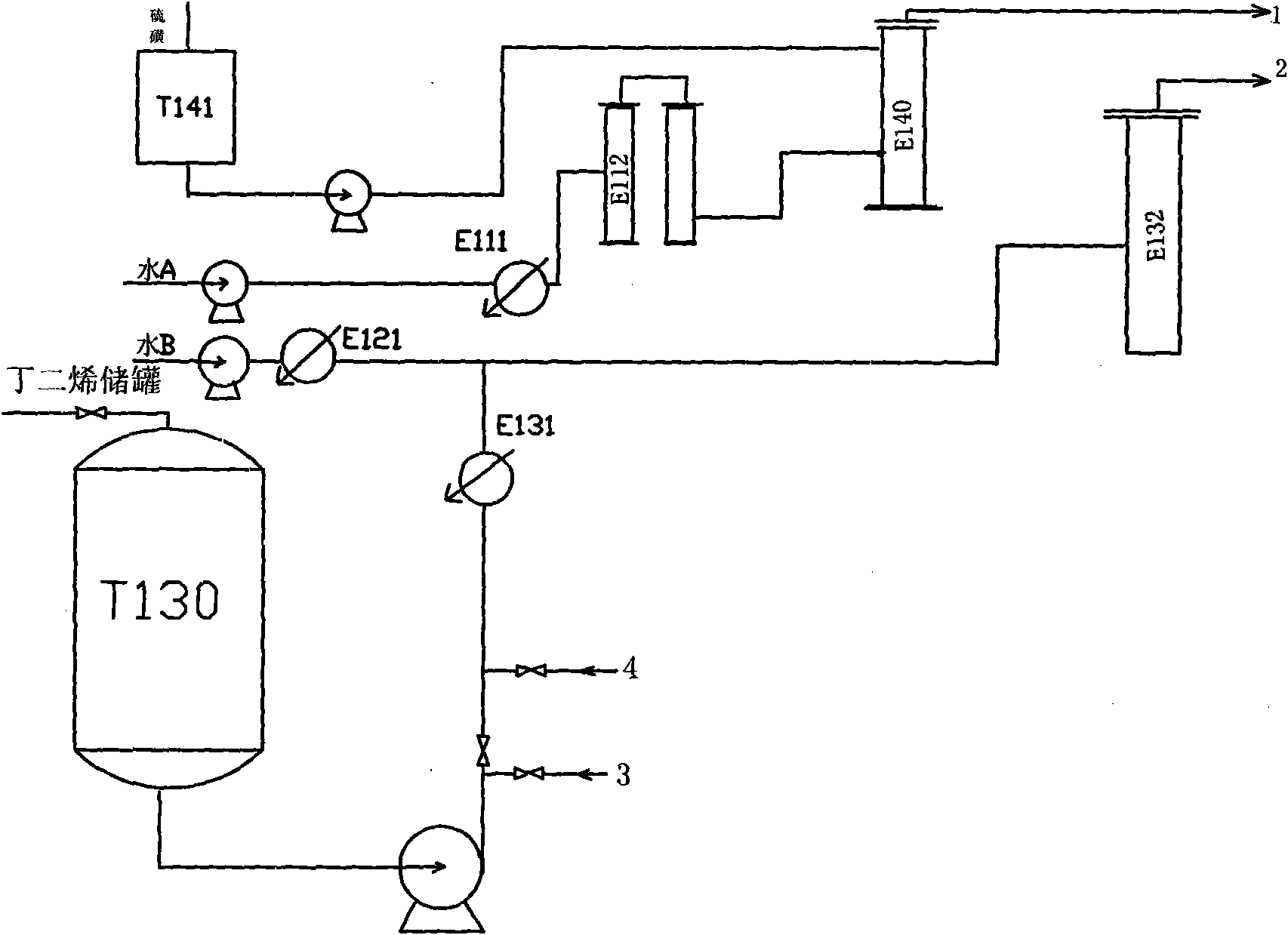

[0074] The butadiene is pumped from the butadiene metering tank T130 to the butadiene vaporizer E131, and the feed rate is 60Kg / h. The water B is pumped to the water B vaporizer E121, and the feed rate is 5Kg / h. The butadiene and water B coming out of the vaporizer enter the butadiene heating furnace H132 together, and are heated to 250°C to obtain water B-butadiene gas.

[0075] The solid sulfur is poured into the sulfur melting tank T141, pumped to the feed inlet on the top of the sulfur heating furnace E140, and the feed rate is 65Kg / h. The water A is pumped to the water A vaporizer E111, the feed rate is 20Kg / h, and then enters the water heating furnace E112 to be heated to 420°C, and then enters the feed inlet below the sulfur heating furnace E140. Water A and sulfur are heated to 540°C in a sulfur furnace to obtain water A-sulfur gas.

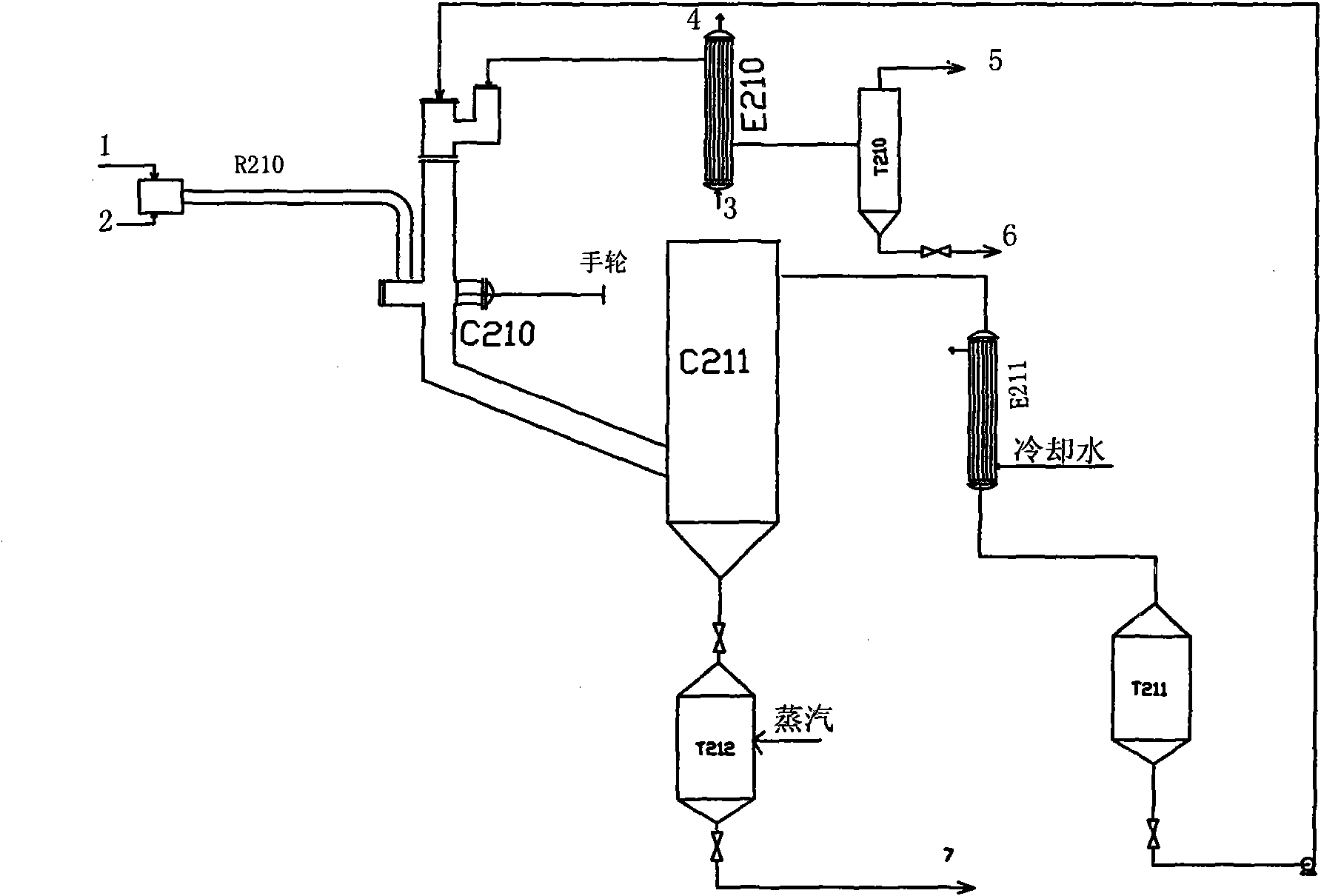

[0076]Water A-sulfur gas and water B-butadiene gas enter the reactor R210 respectiv...

Embodiment 2

[0083] The production of embodiment 2 thiophenes

[0084] Production process and device are with embodiment 1, and its difference is only in:

[0085] The mixing section of the reactor is a φ219×6 stainless steel tube with a length of 0.6 meters; the reaction section is a φ89×6 stainless steel tube with a length of 8 meters. Feed amount butadiene 100Kg / h, sulfur 110Kg / h, water A 35Kg / h, water B 5Kg / h. The reactor inlet temperature is 380°C, the outlet temperature is 450°C, and the pressure is 0.02MPa (gauge pressure). Feed ratio sulfur / butadiene 0.93mol, water / butadiene 1.2mol, reaction residence time 0.92s. The output of thiophene is 1400Kg per day, the unit consumption of butadiene is 1.71 tons, and the yield is 38%. The operation is stopped once every 8 days to clean up the coke in the reactor and the sulfur in the pipeline, and the monthly production of thiophene is 35 tons.

Embodiment 3

[0086] The production of embodiment 3 thiophenes

[0087] Production process and device are with embodiment 1, and its difference is only in:

[0088] The mixing section of the reactor is a φ273×6 tube with a length of 0.8 meters; the reaction section is a φ133×6 stainless steel tube with a length of 8 meters. Feed amount of butadiene 135Kg / h, sulfur 144Kg / h, water A 45Kg / h, water B 10Kg / h. The reactor inlet temperature is 370°C, the outlet temperature is 450°C, and the pressure is 0.02MPa (gauge pressure). Feed ratio sulfur / butadiene 0.9mol, water / butadiene 1.22mol, reaction residence time 1.33s. The output of thiophene is 1750Kg per day, the unit consumption of butadiene is 1.85 tons, and the yield is 35%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com