Tacrolimus sustained-release preparation and preparation method thereof

A technology of tacrolimus and controlled-release preparations, which is applied in the direction of pharmaceutical formulas, medical preparations containing no active ingredients, and medical preparations containing active ingredients. Predict and increase drug solubility and other issues to achieve the effects of reducing the incidence of adverse reactions, improving bioavailability, and improving solubility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

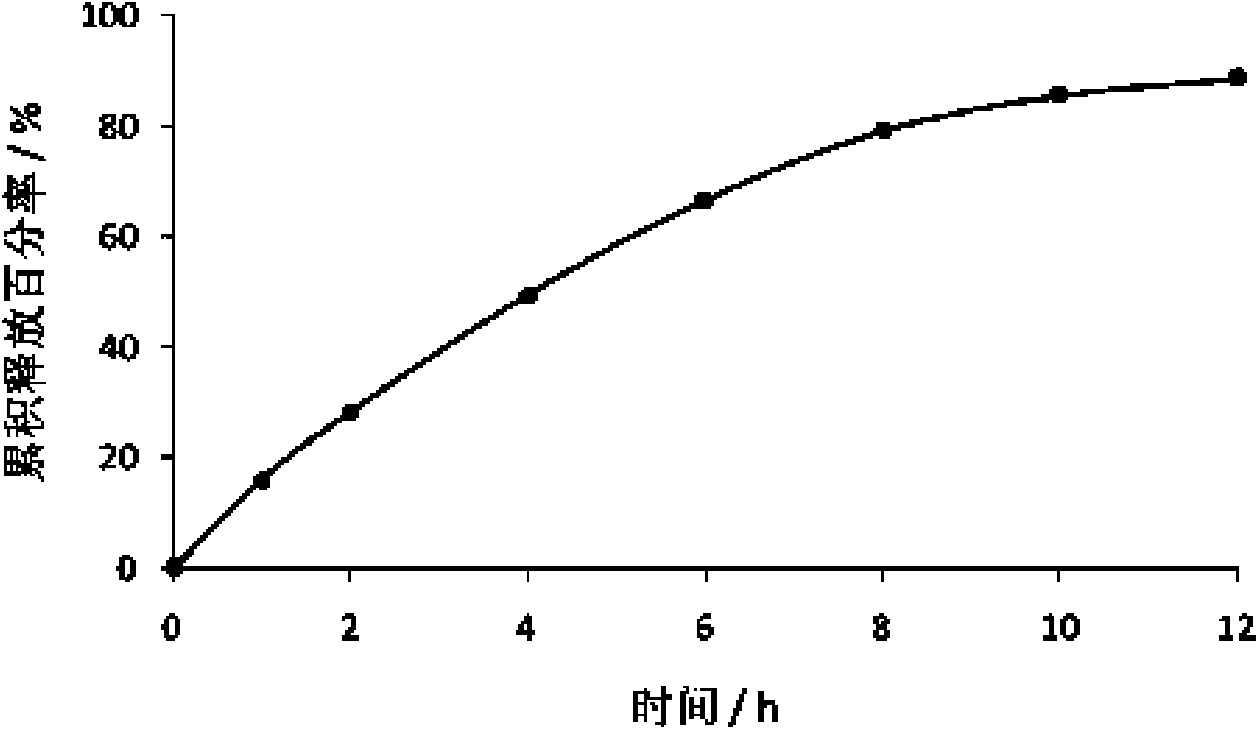

[0075] Example 1 Preparation of Tacrolimus Hydrophilic Gel Matrix Tablets

[0076] Tacrolimus

1g

Hydroxypropyl-β-cyclodextrin

20g

Hydroxypropyl Methyl Cellulose K4M

50g

92g

3.3g

0.8g

A total of 1000 pieces

[0077] Preparation Process:

[0078] After dissolving tacrolimus and hydroxypropyl-β-cyclodextrin with an appropriate amount of absolute ethanol, after ultrasonicating in an ultrasonic instrument for 20 minutes, transfer it to a rotary evaporator to evaporate the solvent to dryness at a temperature of 30-40°C, and precipitate Put the product in a vacuum drying oven at 25-40°C for 24 hours, take it out, grind it, pass through an 80-mesh sieve, and mix it with hydroxypropyl methylcellulose K4M, microcrystalline cellulose, lactose, and magnesium stearate in equal amounts Evenly, the powder is directly compressed ...

Embodiment 2

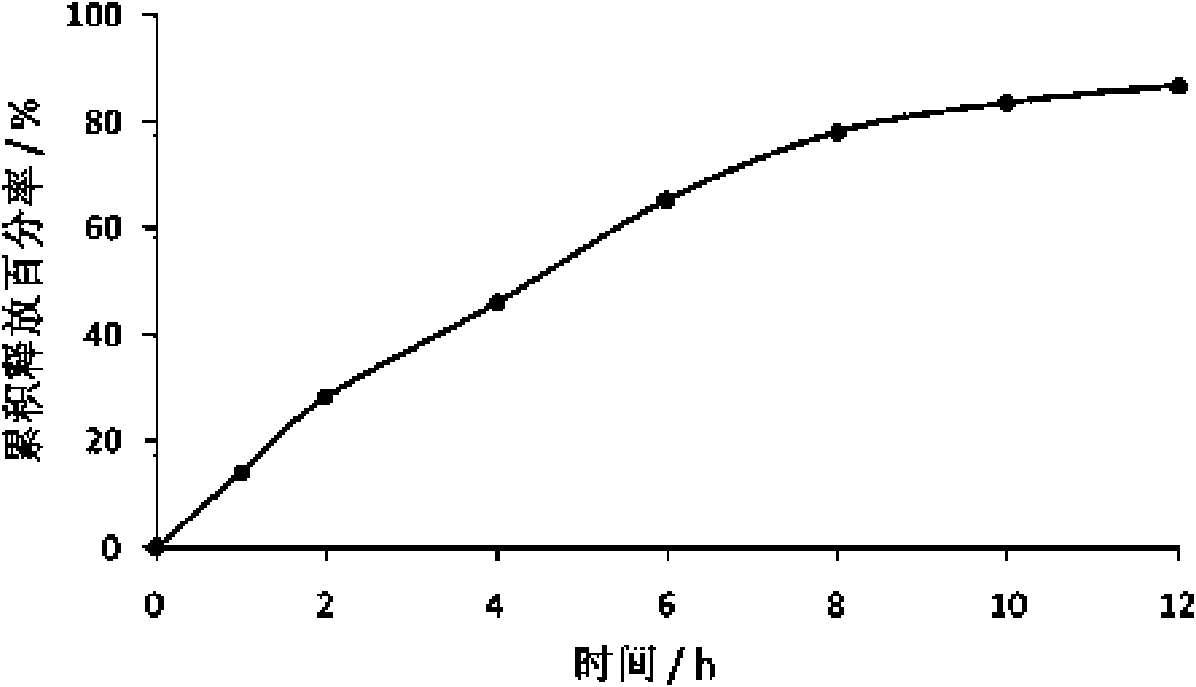

[0080] Example 2 Preparation of Tacrolimus Film Controlled Release Tablets

[0081]

[0082]

[0083] Preparation Process:

[0084] Dissolve tacrolimus in an appropriate amount of ethanol solution, heat polyethylene glycol 6000 in a water bath at 60-70°C until it melts, mix well, stir vigorously, and pour the melt on a stainless steel plate to form a thin layer, making Cool it quickly into a solid, then place the solid in a vacuum oven at 25-40°C for 24 hours, take it out, add a small amount of micropowder silica gel to grind (micropowder silica gel as a lubricant can reduce the loss of solid dispersion during the grinding process), and pass After an 80-mesh sieve, mix it with lactose evenly, add an appropriate amount of 1% polyoxyethylene pyrrolidone aqueous solution, make a soft material, granulate, dry, sieve, granulate, add magnesium stearate, mix evenly, and compress into tablets. The above-mentioned coating material is used for coating, and the release degree is c...

Embodiment 3

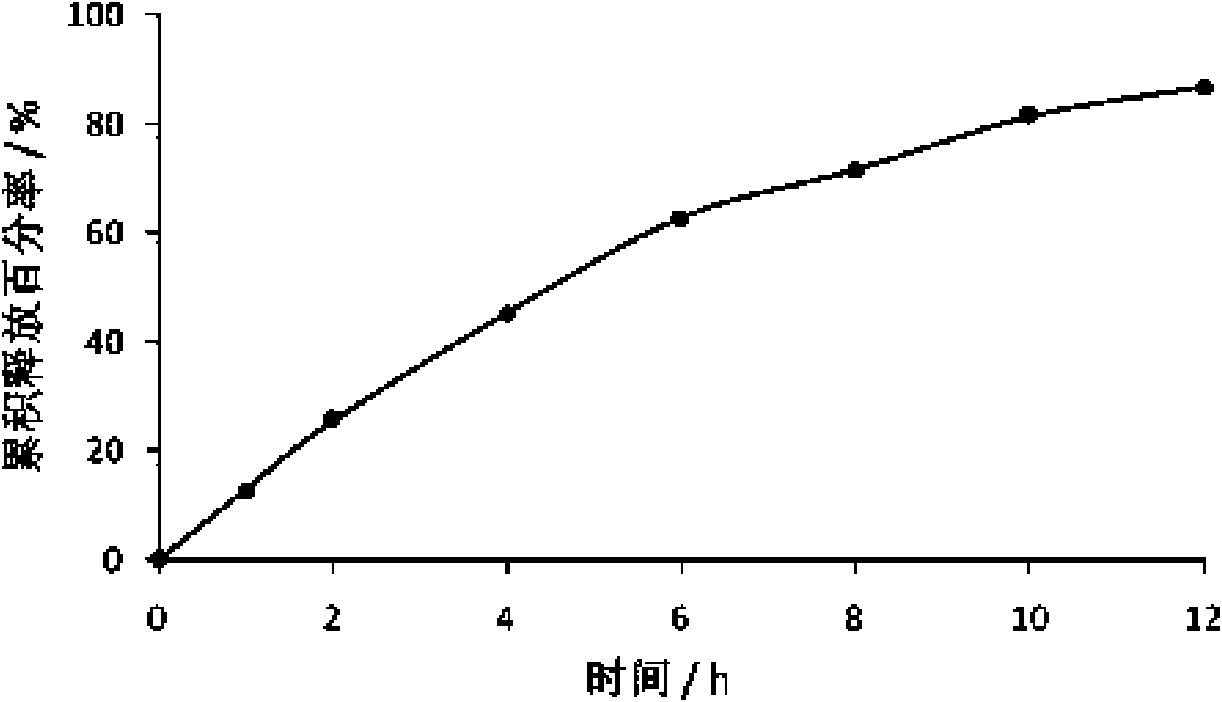

[0086] Example 3 Preparation of Tacrolimus Osmotic Pump Tablets

[0087] Chip

Tacrolimus

1g

Hydroxypropyl-β-cyclodextrin

15g

polyoxyethylene

28g

72g

Magnesium stearate

0.7g

Coating material

Cellulose acetate

12g

polyethylene glycol 400

1.5g

Acetone:water (100:1, v:v)

Appropriate amount

A total of 1000 pieces

[0088] Preparation Process:

[0089] After dissolving tacrolimus and hydroxypropyl-β-cyclodextrin with an appropriate amount of absolute ethanol, after ultrasonicating in an ultrasonic instrument for 20 minutes, transfer it to a rotary evaporator to evaporate the solvent to dryness at a temperature of 30-40°C, and precipitate Put the product in a vacuum oven at 25-40°C for 24 hours, take it out, grind it, pass through an 80-mesh sieve, mix it with polyoxyethylene, sodium chloride, and magnesium ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com