Waxy modified starch, preparation method and application thereof

A technology of modified starch and waxy starch, applied in textiles and papermaking, graft polymer adhesives, adhesive types, etc., can solve the special requirements that cannot meet the properties of starch, and the modified starch cannot meet the technological requirements, etc. problems, to achieve the effect of improving the performance of process products, low cost and good viscosity stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0048] Example 1 Preparation of multiple compound modified waxy starch of the present invention

[0049] Put 1000 grams of pure amylopectin waxy starch (produced by Changchun Dacheng Industrial Group, the branched chain content is greater than 99.0%, and the B-point viscosity of the Brabender viscometer is greater than 620BU) and 1500 grams of clear water into a corrosion-resistant reactor with stirring In the process, keep the starch milk temperature at 40°C, adjust the pH to 7.5-8.5, add 90 grams of monomer acrylamide and 2 grams of initiator potassium persulfate, and react for 3 hours to detect that the grafting rate is greater than 90%; then adjust the pH to 9.5- 11.5, add 5 grams of cross-linking agent phosphorus oxychloride, and react at 25°C for 2.5 hours to detect that the sedimentation volume reaches 40-50; then slowly add 300 grams of sodium hypochlorite (available chlorine content is greater than 11.0%), and maintain the pH at 8.5-9.5 , reacted at 40° C. for 2 hour...

Embodiment 2

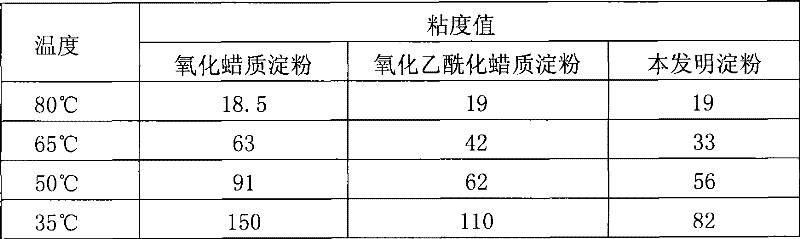

[0053] Example 2 The performance of multiple compound modified starch of the present invention

[0054] The powdery starch product of embodiment 1 is made into the starch paste that weight percent concentration is 1.0%, test the transparency and the viscosity of this starch paste, and respectively with oxidized waxy starch and oxidized acetylated waxy starch (acetyl group content is greater than 1.5%) made the same concentration of starch paste for comparison.

[0055] 1, the transparency of starch of the present invention

[0056] The transparency of the starch paste prepared with the modified starch of the present invention is one of the important indicators to illustrate the quality of the starch, which is related to the degree of aging. Generally, the transparency of those prone to aging is poor.

[0057] The test method of transparency is to take 50ml of 1.0% starch milk in a 100ml beaker, heat it in boiling water for gelatinization, stir for 15 minutes and keep the vo...

Embodiment 3

[0076] Example 3 Application test of modified starch of the present invention for textile sizing

[0077] The waxy modified starch prepared in Example 1 of the present invention was used as an adhesive in the textile industry to carry out a sizing experiment, and at the same time a comparative experiment was carried out with oxidized waxy starch and oxidized acetylated waxy starch.

[0078] The concentration of the starch slurry used in the test was 6%, and the viscosity at 95° C. was 13 cp. The results are shown in Table 3.

[0079] Table 3 Comparison of properties after sizing of three kinds of modified starches

[0080] performance

oxidized waxy starch

oxidized acetylated waxy starch

Starch of the present invention

wear / time

41

44

86

2.75

2.77

3.91

Elongation%

5.39

5.11

4.2

[0081] Break work n·cm

4.26

4.18

5.84

Specific adhesion %

0.27

0.27

0...

PUM

| Property | Measurement | Unit |

|---|---|---|

| degree of grafting | aaaaa | aaaaa |

| degree of grafting | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com