Molecular imprinting monolithic column, preparation method and application thereof

A molecular imprinting and monolithic column technology, applied in chemical instruments and methods, other chemical processes, etc., can solve the problems of interference with 8-OHdG separation and analysis, difficulty in qualitative and quantitative analysis, and complicated operation, and achieve high enrichment ability and selectivity. , long service life and simple preparation method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

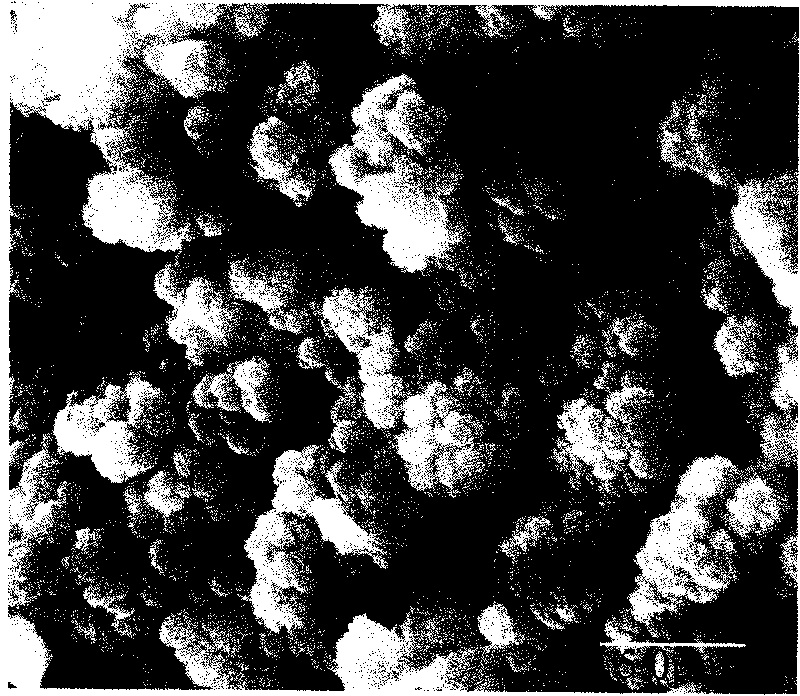

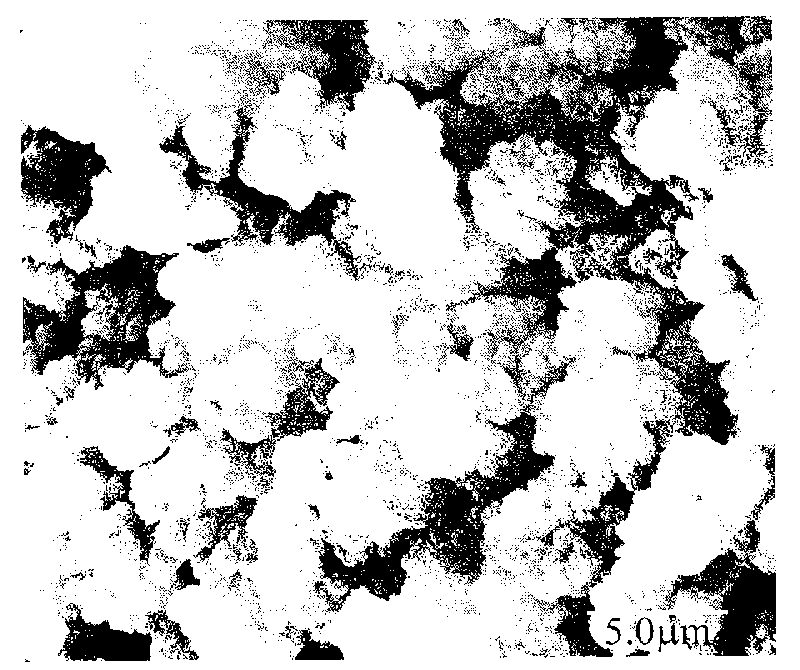

[0017] Example 1 Preparation of Molecularly Imprinted Monolithic Column

[0018] The quartz capillary column was activated with NaOH, then rinsed with HCl and double distilled water, dried and filled with 3-(triethoxysilyl)propyl methacrylate to modify the inner wall of the tube.

[0019] 17.5mg of guanosine, 56mg of acrylamide, 56mg of 4-vinylpyridine, 63mg of N,N'-methylenebisacrylamide and 280mg of dodecanol were ultrasonically dissolved in 350mg of dimethyl sulfoxide in a water bath at 50°C. Nitrogen was blown for 10 minutes to remove the oxygen in the mixture, then 2 mg of azobisisobutyronitrile was added, and after ultrasonic mixing, the mixture was used as the molecularly imprinted prepolymer mixture. Then the molecularly imprinted prepolymer mixture was poured into a capillary column modified with 3-(triethoxysilyl)propyl methacrylate, sealed with silicone rubber, polymerized at a constant temperature of 60° C., and reacted for 18 hours. After the reaction is finished...

Embodiment 2

[0020] Example 2 Preparation of Molecularly Imprinted Monolithic Column

[0021] In the same manner as in Example 1, the inner wall of the quartz capillary was modified with 3-(triethoxysilyl)propyl methacrylate. 17.5mg of guanosine, 55mg of acrylamide, 48mg of 4-vinylpyridine, 62mg of N,N'-methylenebisacrylamide and 275mg of dodecanol were ultrasonically dissolved in 355mg of dimethyl sulfoxide in a water bath at 40°C. Nitrogen gas was blown in for 5 minutes to remove oxygen in the mixture, and then 1.9 mg of azobisisobutyronitrile was added, mixed uniformly by ultrasonic to serve as a molecularly imprinted prepolymer mixed solution. Then the molecularly imprinted prepolymer mixture was poured into a capillary column modified with 3-(triethoxysilyl)propyl methacrylate, sealed with silicone rubber, polymerized at a constant temperature of 55° C., and reacted for 22 hours. After the reaction, the mixed solution of acetonitrile (3mL), methanol and acetic acid (volume ratio of m...

Embodiment 3

[0022] Example 3 Preparation of Molecularly Imprinted Monolithic Column

[0023] In the same manner as in Example 1, the inner wall of the quartz capillary was modified with 3-(trimethoxysilyl)propyl methacrylate. 17.5mg of guanosine, 58mg of acrylamide, 56mg of 4-vinylpyridine, 64mg of N,N'-methylenebisacrylamide and 285mg of dodecanol were ultrasonically dissolved in 360mg of dimethylsulfoxide in a water bath at 50°C. Nitrogen gas was blown in for 5 minutes to remove oxygen in the mixture, and then 2.2 mg of azobisisobutyronitrile was added, mixed uniformly, and then used as a molecularly imprinted prepolymer mixed solution. The molecularly imprinted prepolymer mixture was poured into a capillary column modified with 3-(trimethoxysilyl)propyl methacrylate, sealed with silicone rubber, polymerized at a constant temperature of 60° C., and reacted for 16 hours. After the reaction, the mixed solution of acetonitrile (3mL), methanol and acetic acid (4mL, wherein the volume ratio...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com