Preparation method of poly (lactic acid-glycolic acid)/hydroxyapatite nanofiber compound bracket for bone repair

A technology of hydroxyapatite and glycolic acid, applied in nanostructure manufacturing, phosphorus compounds, nanotechnology and other directions, can solve the problems of difficult to promote the expression of normal activity of osteoblasts, difficult to obtain cell active sites, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

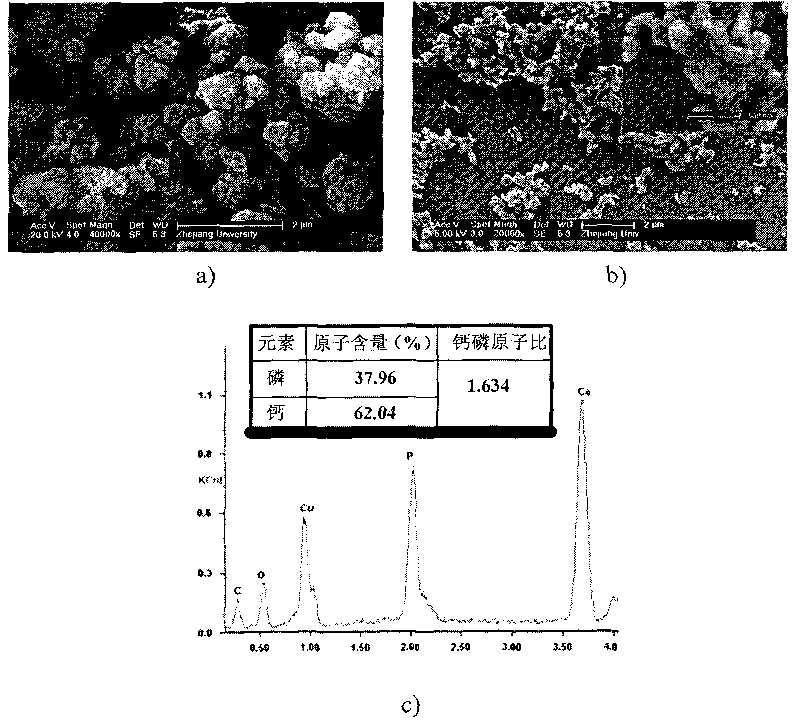

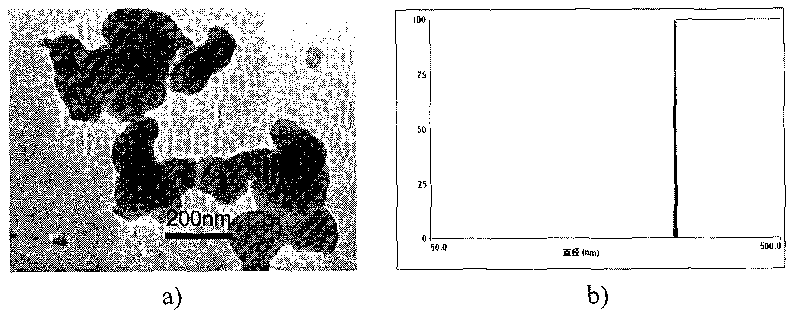

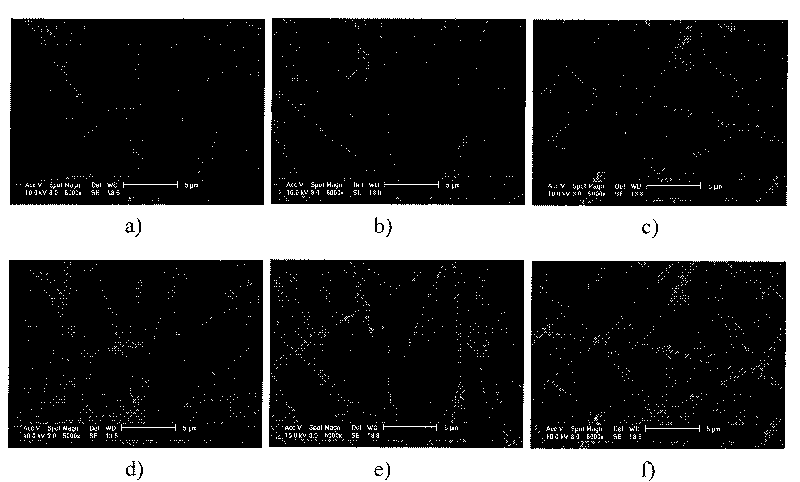

[0026] 1) Dissolve calcium chloride and diammonium hydrogen phosphate in 50g / L polyethylene glycol aqueous solution respectively, prepare the polyethylene glycol aqueous solution of diammonium hydrogen phosphate with a concentration of 0.1mol / L and the polyethylene glycol solution with a concentration of 0.1mol / L The polyethylene glycol aqueous solution of calcium chloride; the polyethylene glycol aqueous solution of diammonium hydrogen phosphate is added dropwise in the polyethylene glycol aqueous solution of calcium chloride, and the calcium phosphorus volume ratio is controlled to be 1.67, and the pH value is adjusted by magnetic stirring was 10, reacted in a water bath at 0°C for 30 minutes, and aged for 48 hours; ultrasonically washed 3 times with deionized water, frozen at -20°C for 2 hours, and freeze-dried in a lyophilizer for 48 hours to obtain amorphous hydroxyl Apatite particles. The amorphous particles were calcined at 900° C. for 4 hours and ultrasonically oscilla...

example 2

[0033] Step 1) is the same as step 1) in Example 1 to obtain granular hydroxyapatite nanocrystals.

[0034] Step 2) is the same as step 2) in Example 1, but the electrospinning flow rate is set at 0.5ml / h to obtain poly(lactic acid-glycolic acid) nanofibrous membrane support and poly(lactic acid-glycolic acid) / hydroxyapatite nanofibers Composite membrane scaffold.

example 3

[0036] Step 1) is the same as step 1) in Example 1 to obtain granular hydroxyapatite nanocrystals.

[0037] Step 2) is the same as step 2) in Example 1, but the electrospinning voltage is set to be 15kV to obtain poly(lactic acid-glycolic acid) nanofiber membrane support and poly(lactic acid-glycolic acid) / hydroxyapatite nanofiber composite membrane stand.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com