Method for preparing lithium ferrous phosphate

A technology of lithium ferrous phosphate and hydrated iron phosphate, applied in the field of material science, can solve the problems of difficult mixing of reactants, poor electrochemical performance, irregular morphology, etc., achieve good electrochemical performance, improve electrical conductivity, cycle time short effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

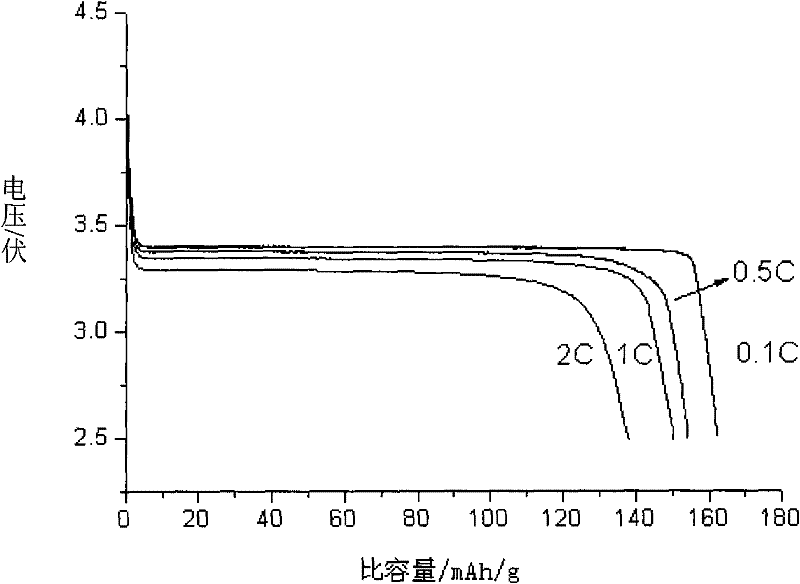

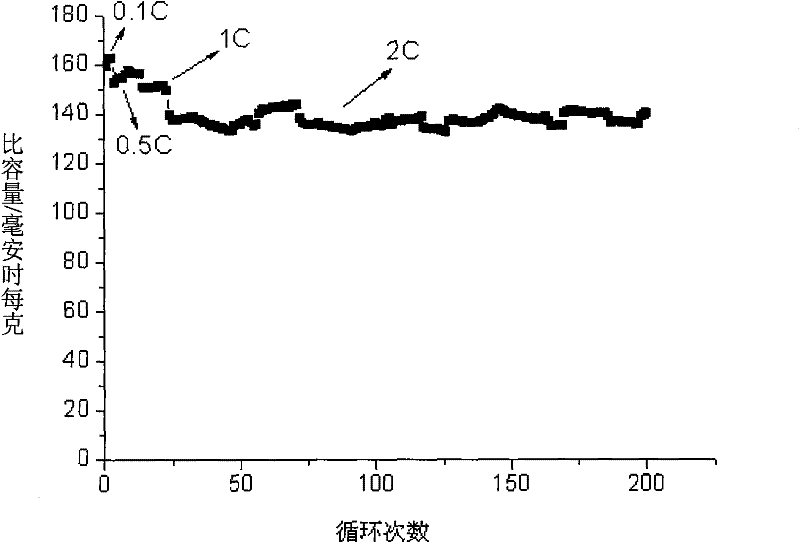

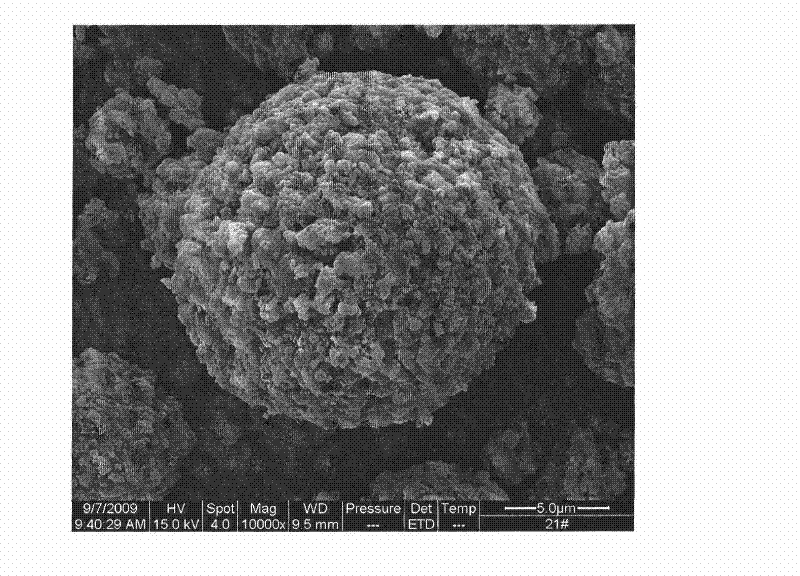

Embodiment 1

[0028] Get 620g hydrated iron phosphate FePO 4 .2H 2 O was dehydrated in an air atmosphere at a heating rate of 4°C / min to 550°C for 10 hours to obtain anhydrous iron phosphate powder. Weigh 110g of sucrose, 500g of anhydrous ferric phosphate and 125g of lithium carbonate (Li:C:Fe=1.02:1.16:1), add 1000ml of water, and mix in a basket ball mill for 2 hours at a high speed at a ball milling speed of 1200rpm to form a uniform slurry Material (solid content of slurry 38%). The average particle diameter D50 of suspended solid particles in the slurry is 0.5 microns. The obtained slurry is dried with an air-flow spray dryer, adopting a co-current drying method, and the atomization device adopts a double-flow nozzle. Feed with a peristaltic pump at a feed rate of 15ml / min. The gas flow rate of the nozzle is controlled by the pressure of compressed air, atomization is generated at about 0.4MPa, the air inlet temperature is controlled to be 300°C, the outlet temperature is 120°C, a...

Embodiment 2

[0031] Get 620g hydrated iron phosphate FePO 4 .2H 2 O was dehydrated by roasting at 300°C for 12 hours in an air atmosphere to obtain anhydrous iron phosphate powder. Take by weighing 120g glucose, 500g anhydrous ferric phosphate and 145g lithium hydroxide (LiOH.H 2 O) (Li: C: Fe=1.04: 1.2: 1), add 1500ml of water, mix 2hr in the high-speed ball mill in the basket ball mill, 2000rpm of ball milling speed, form uniform slurry (slurry solid content 34%), slurry The average particle diameter D50 of suspended solid particles in the medium is 0.3 microns. The obtained slurry is dried with an air-flow spray dryer, adopting a co-current drying method, and the atomization device adopts a double-flow nozzle. Feed with a peristaltic pump at a feed rate of 10ml / min. The gas flow rate of the nozzle is controlled by the pressure of the compressed air, atomization is generated at about 0.4MPa, the air inlet temperature is controlled at 260°C, the outlet temperature is 110°C, and the ou...

Embodiment 3

[0034] Get 620g hydrated iron phosphate FePO 4 .2H 2 O was dehydrated by roasting at 450°C for 6 hours in an air atmosphere to obtain anhydrous iron phosphate powder. Take by weighing 100g pentaerythritol, 500g anhydrous iron phosphate and 350g lithium acetate (CH 3 COOLi.2H 2O) (Li: C: Fe=1.03: 1.11: 1), add 1000ml of water, mix 2hr in the high-speed ball mill in the basket ball mill, the ball mill rotating speed 1500rpm, form uniform slurry (solid content of slurry 49%), slurry The average particle diameter D50 of suspended solid particles in the medium is 0.6 microns. The obtained slurry is dried with an air-flow spray dryer, adopting a co-current drying method, and the atomization device adopts a double-flow nozzle. Feed with a peristaltic pump at a feed rate of 10ml / min. The gas flow rate of the nozzle is controlled by the pressure of the compressed air, atomization is generated at about 0.4MPa, the air inlet temperature is controlled to be 300°C, the outlet temperat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com