Acrylic ester polymer emulsion and preparation method thereof

A polymer emulsion and acrylate technology, applied in the field of acrylate polymer emulsion and its preparation, can solve the problems of low drying yield, poor redispersion film-forming property, poor water resistance, etc., and achieve good re-dispersion performance and film-forming performance , The effect of improving water resistance, mechanical properties and bonding properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

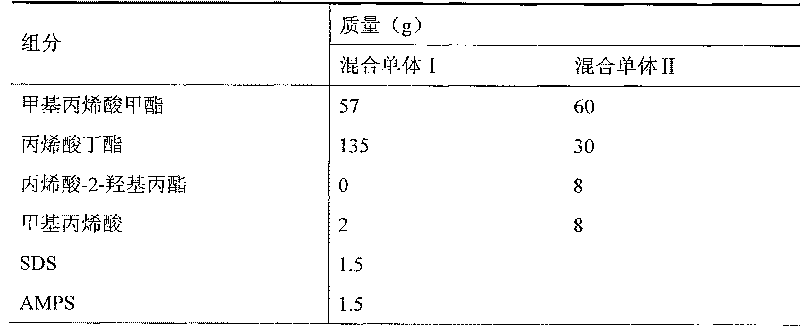

[0043] The composition of acrylate polymer emulsion comprises methyl methacrylate, butyl acrylate, 2-hydroxyethyl acrylate, methacrylic acid, and its specific component formula is as follows table 1:

[0044] Table 1

[0045]

[0046]

[0047] The preparation method of acrylate polymer emulsion, its step is as follows:

[0048] a. Mix the above-mentioned quality of alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester and methacrylic acid respectively to prepare mixed monomer I and mixed monomer II. According to the FOX formula, the Tg of the copolymer composed of the mixed monomer I is -21.9°C, and the Tg of the copolymer composed of the mixed monomer I is 36.5°C.

[0049] B, preparation of seed emulsion: join the above-mentioned quality 60% water, 50% emulsifier and 30% initiator in the reaction kettle equipped with thermometer, agitator, feeding pipe, condensing reflux pipe, stir and disperse for 15 minutes, wait The temperature was raised to 80° C., and 10% of the...

Embodiment 2

[0054] The composition of acrylate polymer emulsion includes methyl methacrylate, ethyl methacrylate, butyl acrylate, isooctyl acrylate, 2-hydroxyethyl acrylate, 3-hydroxypropyl acrylate, acrylic acid, and its specific composition The allocation party is as follows in Table 2:

[0055] Table 2

[0056]

[0057]

[0058] The preparation method of acrylate polymer emulsion, its step is as follows:

[0059] a. Mix the above mass parts of alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester and methacrylic acid respectively to prepare mixed monomer I and mixed monomer II. According to the FOX formula, the Tg of the copolymer composed of the mixed monomer I is -39.5°C, and the Tg of the copolymer composed of the mixed monomer I is 49.8°C.

[0060] b. Preparation of seed emulsion: join the above-mentioned 70% water by mass, 40% emulsifier and 50% initiator into a reaction kettle equipped with a thermometer, agitator, feeding pipe, and condensing reflux pipe, stir and dispe...

Embodiment 3

[0065] The composition of acrylate polymer emulsion includes ethyl methacrylate, propyl methacrylate, ethyl acrylate, butyl acrylate, 2-hydroxyethyl acrylate, 5-hydroxypentyl acrylate, methacrylic acid, and its composition The allocation party is as follows in Table 3:

[0066] table 3

[0067]

[0068] The preparation method of acrylate polymer emulsion, its step is as follows:

[0069] a. Mix the above mass parts of alkyl methacrylate, alkyl acrylate, hydroxyalkyl ester and methacrylic acid respectively to prepare mixed monomer I and mixed monomer II. According to the FOX formula, the Tg of the copolymer composed of the mixed monomer I is -32.0°C, and the Tg of the copolymer composed of the mixed monomer I is 43.7°C.

[0070] b. Preparation of seed emulsion: join the above-mentioned 80% water by mass, 60% emulsifier and 40% initiator into a reaction kettle equipped with a thermometer, agitator, feeding pipe, and condensing reflux pipe, stir and disperse for 20 minutes, ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| glass transition temperature | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com