Method for preparing polyvinylidene fluoride/aluminum oxide hybridization film

A polyvinylidene fluoride, alumina technology, applied in chemical instruments and methods, membrane technology, semi-permeable membrane separation, etc., can solve the problems of high particle size requirements of inorganic particles, decreased separation performance, uneven membrane structure, etc. Achieve the effect of improving phase separation, avoiding flocculation, and improving hydrophilicity and strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

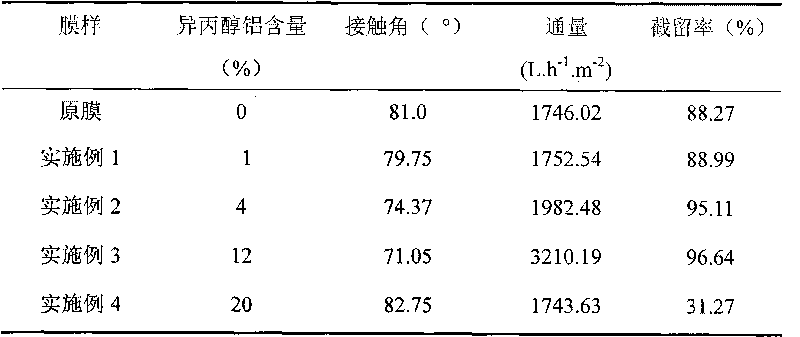

Embodiment 1

[0025] Add 20 grams of polyvinylidene fluoride into 92.43 grams of N,N-dimethylacetamide solvent, stir and dissolve at 70°C, add 0.2 grams of aluminum isopropoxide and 0.2 grams of vinyltrimethoxysilane, and stir for 1 hour Add 0.09g of deionized water, hydrolyze at 90°C for 1h, then cool down to 55°C, add 0.01g of HNO 3 Catalytic peptization and 4.7 g of polyvinylpyrrolidone were used as a pore-forming agent, and stirring was continued for 20 hours at 90° C. to obtain 117.63 g of a uniform casting solution. The above solution was allowed to stand at room temperature for 24 hours to defoam.

[0026] Scrape the flat film from the casting solution after defoaming at room temperature, place it in the air for 30 seconds, and then completely immerse it in the coagulation bath, which is deionized water. The formed ultrafiltration membrane is soaked in deionized water for 7 days. Allow to air dry.

Embodiment 2

[0028] Add 20 grams of polyvinylidene fluoride into 91.5 grams of N,N-dimethylacetamide solvent, stir and dissolve at 70°C, add 0.8 grams of aluminum isopropoxide and 0.2 grams of vinyltrimethoxysilane, and stir for 1 hour Add 0.36 g of water, hydrolyze at 90°C for 1 hour, then cool down to 55°C, add 0.04 g of HNO 3 Catalyzed peptization and 4.7 g of polyvinylpyrrolidone were used as a pore-forming agent, and 117.60 g of uniform casting solution was obtained by continuing to stir at 90° C. for 24 hours. The above solution was allowed to stand at room temperature for 24 hours to defoam.

[0029] Scrape the flat film from the defoamed casting solution at room temperature, place it in the air for 30 seconds, then immerse it in the coagulation bath, the coagulation bath is water, and soak the formed ultrafiltration membrane in deionized water for 7 days, take out Allow to air dry.

Embodiment 3

[0031] Add 20 grams of polyvinylidene fluoride into 89.02 grams of N,N-dimethylacetamide solvent, stir and dissolve at 70°C, add 2.4 grams of aluminum isopropoxide and 0.2 grams of vinyltrimethoxysilane, and stir for 1 hour Add 1.08g of water, hydrolyze at 90°C for 1h, then cool down to 55°C, add 0.12g of HNO 3 Catalyzed peptization and 4.7 g of polyvinylpyrrolidone were used as a pore-forming agent, and stirring was continued at 90° C. for 24 hours to obtain 117.52 g of a uniform casting solution. The above solution was allowed to stand at room temperature for 24 hours to defoam.

[0032] Scrape the flat film from the degassed casting solution at room temperature, place it in the air for 30 seconds, then completely immerse it in deionized water, soak the formed ultrafiltration membrane in deionized water for 7 days, take it out and dry it in the air.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com