Method for synthesizing copper-indium-selenium nanocrystalline

A synthesis method and nanocrystal technology are applied in the field of solar cell materials to achieve the effects of strong operability, simple synthesis device and low reaction cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

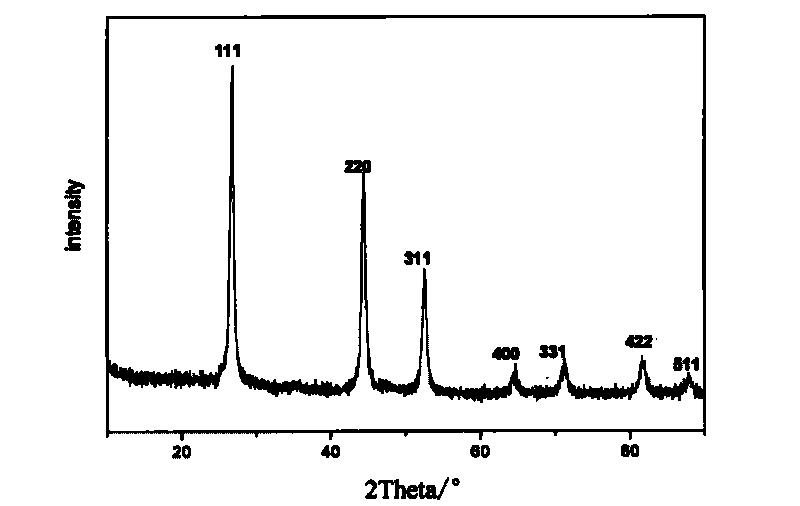

Image

Examples

Embodiment 1

[0020] (1) In a 25ml snap-top bottle, add 0.3ml of dodecyl mercaptan and 5ml of oleylamine and mix evenly, then add 0.08g of elemental selenium, ultrasonically disperse at room temperature for 10min to obtain a uniformly dispersed selenium solution, and finally transfer the solution into the constant pressure funnel.

[0021] (2) Operate and weigh 0.11gInCl in the glove box 3 and 0.05g CuCl in a 50ml three-neck round bottom flask, then add 6ml oleic acid and 9ml octadecene.

[0022] (3) Install the reaction device: one side port of the three-neck bottle is connected to the constant pressure funnel in step (1), and the other side side pipe is connected to the temperature probe of the built-in heating jacket of the glass sleeve to measure the temperature of the reaction solution. The middle port is connected to the reflux condenser, and the vacuum line is connected to the condenser for vacuuming and nitrogen. Finally, the three-necked bottle was placed in a magnetic heating st...

Embodiment 2

[0029] (1) In a 25ml snap-top bottle, add 0.5ml of dodecyl mercaptan and 5ml of oleylamine and mix evenly, then add 0.08g of elemental selenium, ultrasonically disperse at room temperature for 10min to obtain a uniformly dispersed selenium solution, and finally transfer the solution into the constant pressure funnel.

[0030] (2) Weigh 0.22gInCl in the glove box 3 and 0.05g CuCl in a 50ml three-neck round bottom flask, then add 6ml oleic acid and 9ml octadecene.

[0031] (3) Install the reaction device: one side port of the three-neck bottle is connected to the constant pressure funnel in step (1), and the other side side pipe is connected to the temperature probe of the built-in heating jacket of the glass sleeve to measure the temperature of the reaction solution. The middle port is connected to the reflux condenser, and the vacuum line is connected to the condenser for vacuuming and nitrogen. Finally, the three-necked bottle was placed in a magnetic heating stirrer.

[0...

Embodiment 3

[0037] (1) In a 25ml snap bottle, add 0.7ml of dodecyl mercaptan and 5ml of oleylamine and mix evenly, then add 0.08g of elemental selenium, ultrasonically disperse at room temperature for 10min to obtain a uniformly dispersed selenium solution, and finally transfer the solution into the constant pressure funnel.

[0038] (2) Weigh 0.22gInCl in the glove box 3 and 0.05g CuCl in a 50ml three-neck round bottom flask, then add 6ml oleic acid and 9ml octadecene.

[0039] (3) Install the reaction device: one side port of the three-neck bottle is connected to the constant pressure funnel in step (1), and the other side side pipe is connected to the temperature probe of the built-in heating jacket of the glass sleeve to measure the temperature of the reaction solution. The middle port is connected to the reflux condenser, and the vacuum line is connected to the condenser for vacuuming and nitrogen. Finally, the three-necked bottle was placed in a magnetic heating stirrer.

[0040]...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com