Red phosphor and preparation method thereof

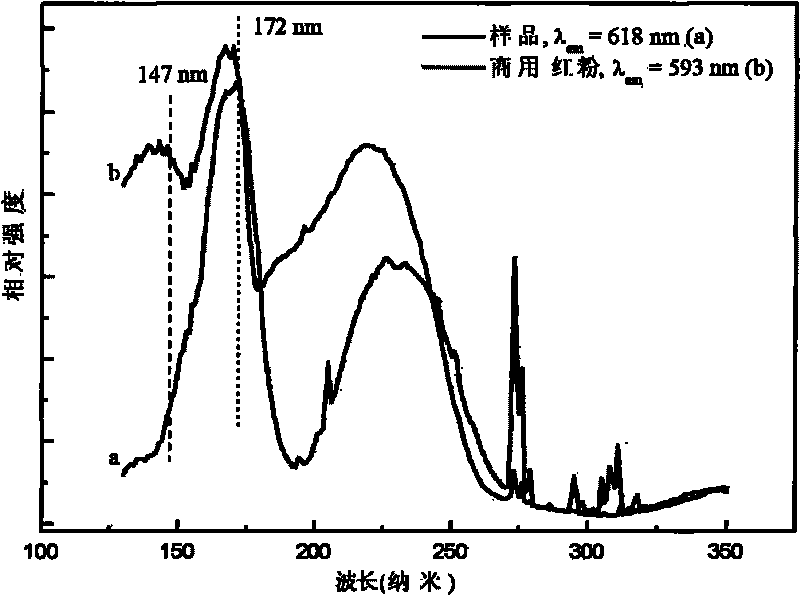

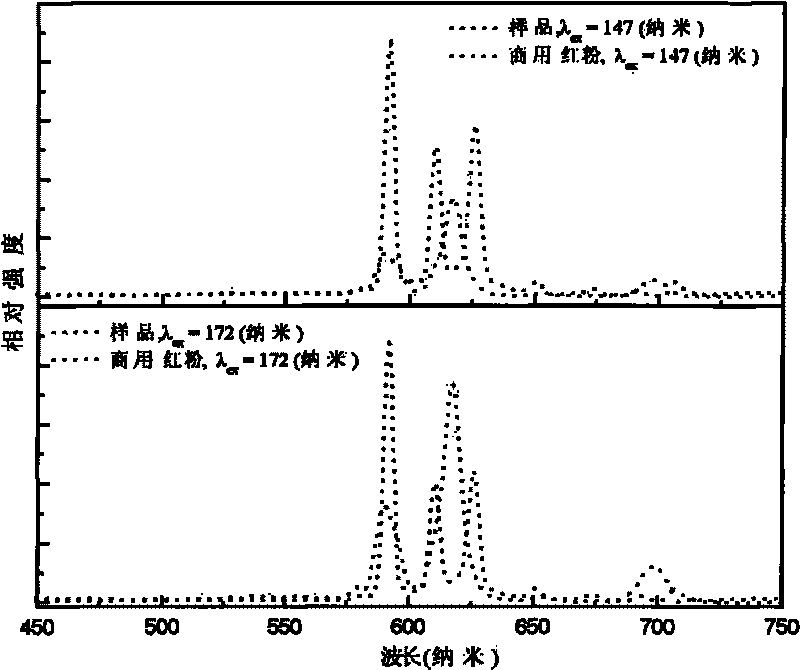

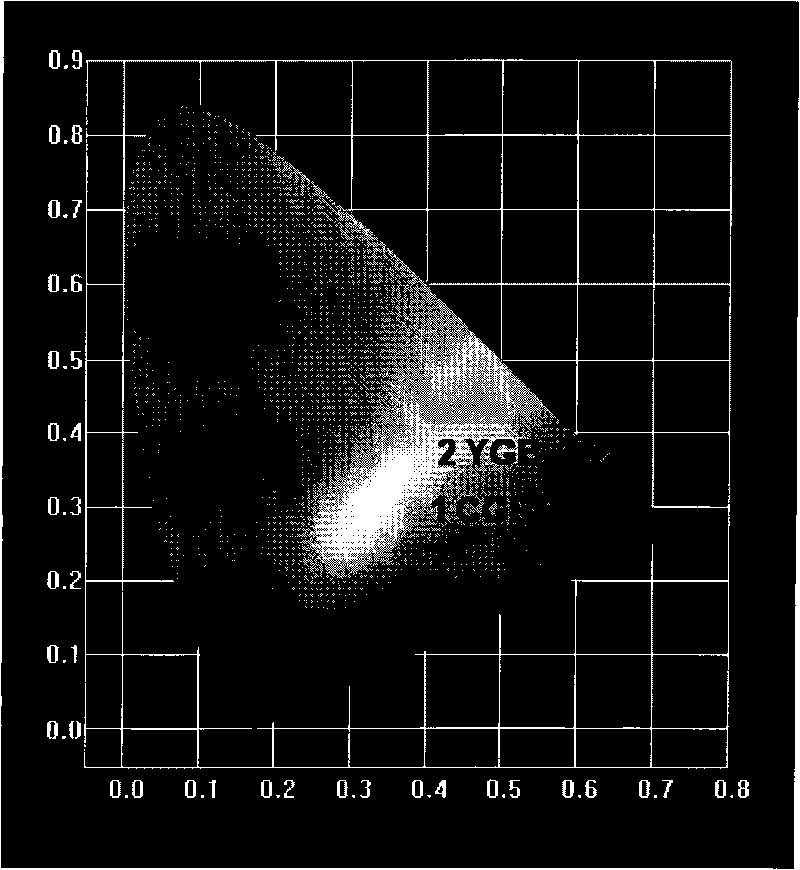

A technology of red phosphor powder and chemical composition, applied in chemical instruments and methods, luminescent materials, etc., can solve the problem of mismatching color coordinates, and achieve the effects of good color coordinates, easy operation and high emission intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0020] Weigh lanthanum trioxide (La 2 o 3 )0.5241g, europium oxide (Eu 2 o 3 ) 0.0205g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4 F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered at 1050°C for 4 hours in a carbon monoxide atmosphere, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

Embodiment 2

[0022] Weigh gadolinium trioxide (Gd 2 o 3 )0.5830g, europium oxide (Eu 2 o 3 ) 0.0205g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4 F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered at 1050°C for 4 hours in a carbon monoxide atmosphere, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

Embodiment 3

[0024] Weigh diyttrium trioxide (Y 2 o 3 )0.3632g, europium oxide (Eu 2 o 3 ) 0.0205g, calcium carbonate (CaCO 3 ) 1.0009g, sodium carbonate (Na 2 CO 3 ) 0.1943g, ammonium dihydrogen phosphate (NH 4 h 2 PO 4 ) 1.1504g, ammonium fluoride (NH 4 F) 0.1729g, fully ground in an agate mortar and mixed evenly, sintered at 1050°C for 4 hours in a carbon monoxide atmosphere, cooled to room temperature, and the sample was taken out and ground to finally obtain the product.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com