Method for preparing icing-resistant copper surface with super hydrophobicity and low adhesiveness

A technology of copper surface and adhesion, applied in the field of anti-coated matte surface preparation, can solve the problems of poor rolling performance of water droplets, difficulty in large-scale production, unbalanced ratio, etc., and achieve excellent superhydrophobicity, low adhesion, and contact area The effect of reducing and increasing energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

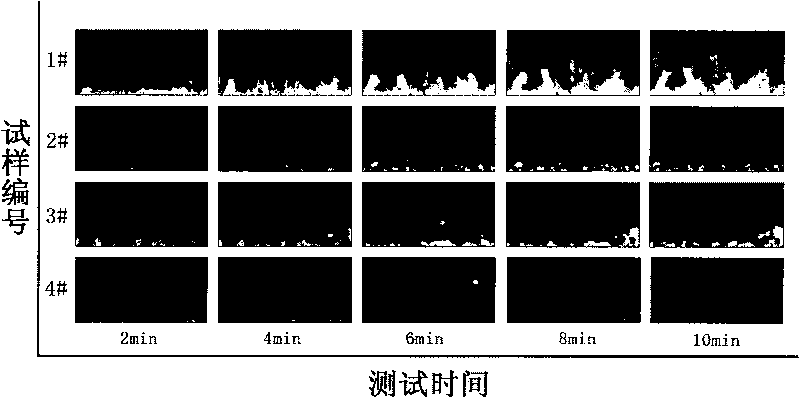

Examples

preparation example Construction

[0016] A preparation method of a super-hydrophobic low-adhesion anti-icing copper surface, the preparation method comprising the following steps:

[0017] (1) Sandblasting the copper surface with micron brown corundum sand pellets to form a micron rough structure on the copper surface; the number of sand pellets is 36-150, the air pressure is 0.2-0.8MPa, and the spraying time is 1 -5min; In this embodiment, the number of sand pellets is 36 mesh, 150 mesh or 60 mesh, the air pressure is 0.2MPa, 0.8MPa or 0.45MPa, and the injection time is 1min, 5min or 4min;

[0018] (2) Ultrasonic cleaning and drying of the copper surface after sandblasting, and then adopting the surface oxidation method to obtain a micro / nano composite structure on the copper surface; the surface oxidation method is: immersing the sandblasted copper into a water bath and heating it to 50 In the mixed aqueous solution at -90℃, take out and rinse with water after 20-60min in the water bath, and then dry in a constan...

example 1

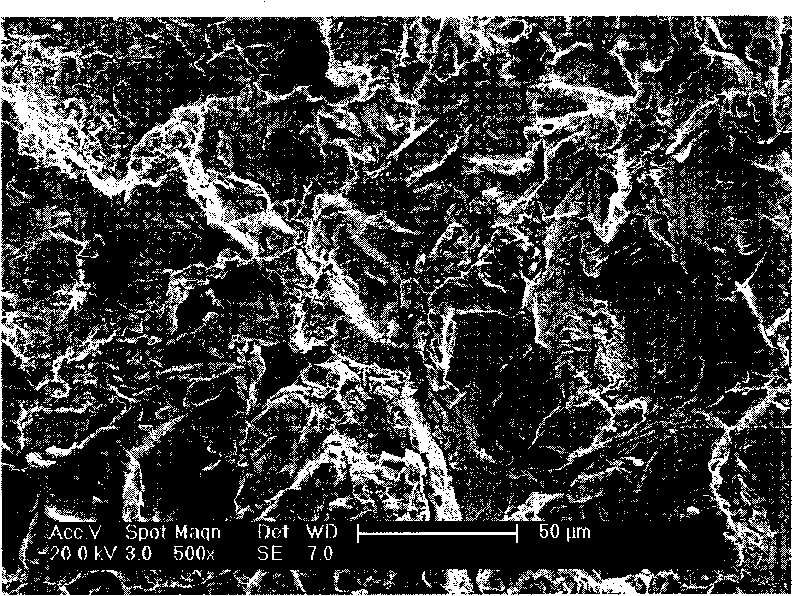

[0021] 1. Use pneumatic sand blasting equipment to spray 80 mesh brown corundum sand shots on the copper surface for 3 minutes at a blast pressure of 0.8 MPa to build a micron-level structure on the surface ( figure 1 ). Then put the blasted copper sheet into clean water for ultrasonic cleaning for 3 minutes.

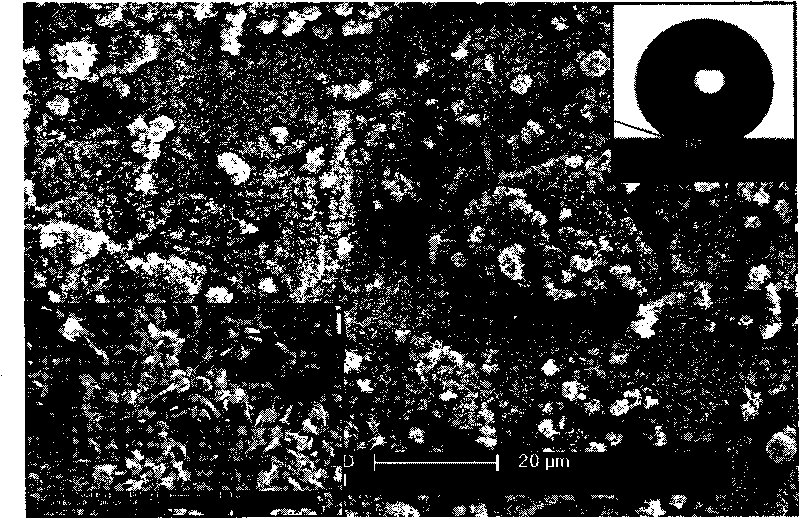

[0022] 2. The concentration of potassium persulfate in the aqueous solution for surface oxidation is 0.065 mol / L, and the concentration of potassium hydroxide is 2.5 mol / L. The sand-blasted and cleaned copper sheet is immersed in the above-prepared aqueous solution to construct a nano-scale structure on the basis of the micro-scale structure constructed by the sandblasting treatment. The temperature of the water bath is controlled at 60°C, the sample is placed for 30 minutes and then taken out, then placed in clean water for ultrasonic cleaning for 3 minutes, and dried in a constant temperature oven at 180°C for 2 hours.

[0023] 3. The solvent of the fluorosilane solution ...

example 2

[0031] 1. Use pneumatic sandblasting equipment to spray 36-mesh brown corundum sand pellets on the copper surface for 5 minutes at a sandblasting pressure of 0.6MPa to build a micron-level structure on the surface. Then put the blasted copper sheet into clean water for ultrasonic cleaning for 3 minutes.

[0032] 2. The concentration of potassium persulfate in the aqueous solution for surface oxidation is 0.05 mol / L, and the concentration of potassium hydroxide is 3 mol / L. The sand-blasted and cleaned copper sheet is immersed in the above-mentioned prepared aqueous solution to construct a nano-scale structure on the basis of the micro-scale structure constructed by the sand-blasting treatment. The temperature of the water bath is controlled at 80°C, the sample is placed for 45 minutes and then taken out, then put in clean water for ultrasonic cleaning for 3 minutes, and dried in a constant temperature oven at 200°C for 1 hour.

[0033] 3. The solvent of the fluorosilane solution fo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com