Lightweight and broadband wave absorbing material with foam sandwich structure and method for producing same

A wave-absorbing material and interlayer structure technology, which is applied in the field of lightweight broadband electromagnetic wave structure absorbing materials and its preparation, can solve the problems of inability to prepare foam structure wave-absorbing materials, low mechanical properties of polyurethane soft foam, and poor low-frequency band effects, etc. , to achieve superior environmental performance, light surface density, and good low-frequency performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

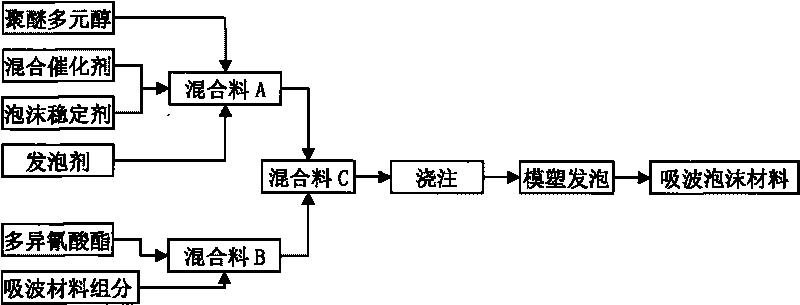

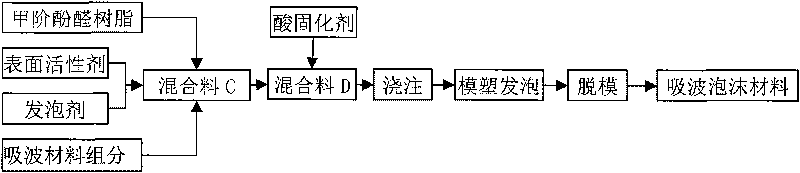

[0022] Preparation method of wave-absorbing foam material layer

[0023] 1. Polyurethane absorbing foam material

[0024] Step 1 Mix polyether polyol (mass parts: 100), mixed catalyst (0.15-0.5), foam stabilizer (1.5-3), foaming agent (8-18) to make a combined polyether (mixture A);

[0025] Step 2: Mix organic polyisocyanate (100-50) and wave-absorbing material components (1-20) evenly to make mixture B;

[0026] Step 3 mixes the mixture A and B of step 1 and step 2 evenly to make mixture C;

[0027] Step 4: Rapidly inject the compound C in step 3 into the preheated (temperature 40°C-60°C) mold, and lock the mold to make it foam. Open the mold after 30 to 60 minutes to get the desired finished product.

[0028] Process flow chart such as figure 2 shown.

[0029] Wherein, the polyether polyols in step 1 include sucrose polyethers, sorbitol polyethers, glycerol polyethers and aromatic polyethers; catalysts include tertiary amine compounds (such as triethylamine, triethyl...

Embodiment 1

[0078]The chopped magnetic carbon fiber (1.5 mm in length) with a mass part of 1 was added to the raw materials for preparing the polyurethane absorbing foam according to the aforementioned preparation process of the polyurethane absorbing foam, and a polyurethane absorbing foam with a single layer thickness of 10 mm was prepared. Material Single layer board (sandwich).

[0079] Press the sandwich core prepared above with a 2mm thick glass fiber board (panel) and a 3mm thick magnetic carbon fiber absorbing reflection layer (bottom plate) figure 1 Bonded together to form a sandwich structure absorber.

[0080] The reflectivity of the material is less than -1dB in the entire 4-14GHz frequency band, less than -5dB in the 14-17 frequency band, and has an absorption peak at 15.7, reaching -7.4dB.

Embodiment 2

[0082] The chopped magnetic carbon fiber (length is 2.5mm) of 1 mass part is added to the raw material for preparing the phenolic resin wave-absorbing foam material according to the preparation process of the aforementioned phenolic resin wave-absorbing foam material, and a single-layer thickness of 10mm is prepared. Single layer panel (sandwich) of absorbing foam material.

[0083] Press the sandwich core prepared above with a 2mm thick glass fiber board (panel) and a 3mm thick magnetic carbon fiber absorbing reflection layer (bottom plate) figure 1 Bonded together to form a sandwich structure absorber.

[0084] The reflectivity of this material is less than -1dB in the whole 3-15GHz frequency band, less than -5dB in the 15-17.5 frequency band, and has an absorption peak at 16.2, reaching -7.8dB.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com