Copper-indium-selenium nanowire array and preparation method and application thereof

A nanowire array, copper indium selenide technology, applied in nanostructure manufacturing, nanotechnology, nanotechnology and other directions, can solve the problems of small share and high manufacturing cost, and achieve high conversion efficiency, low cost, and increased junction area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

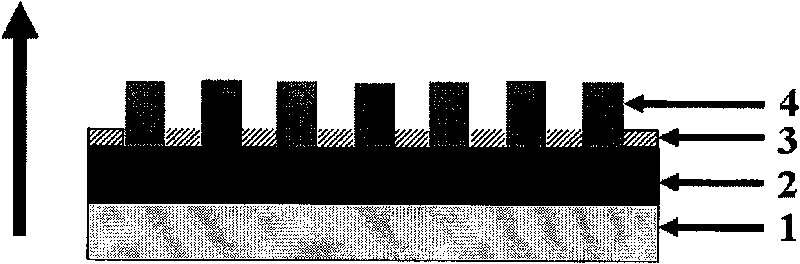

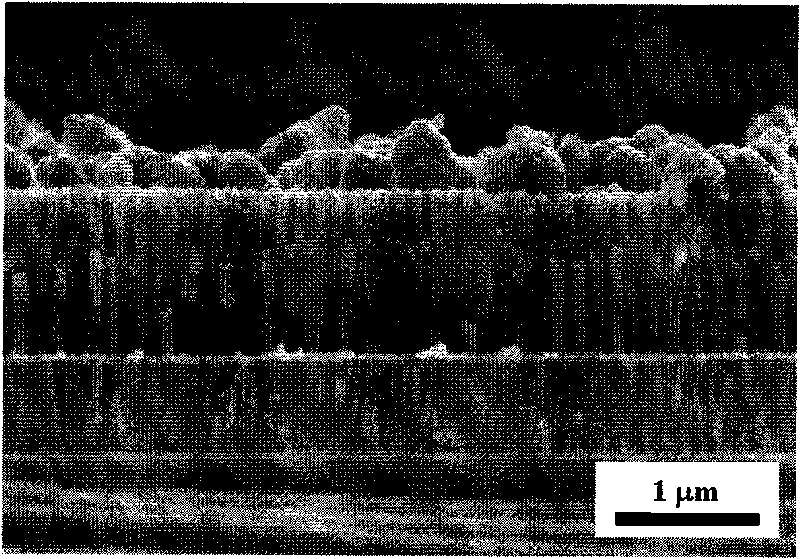

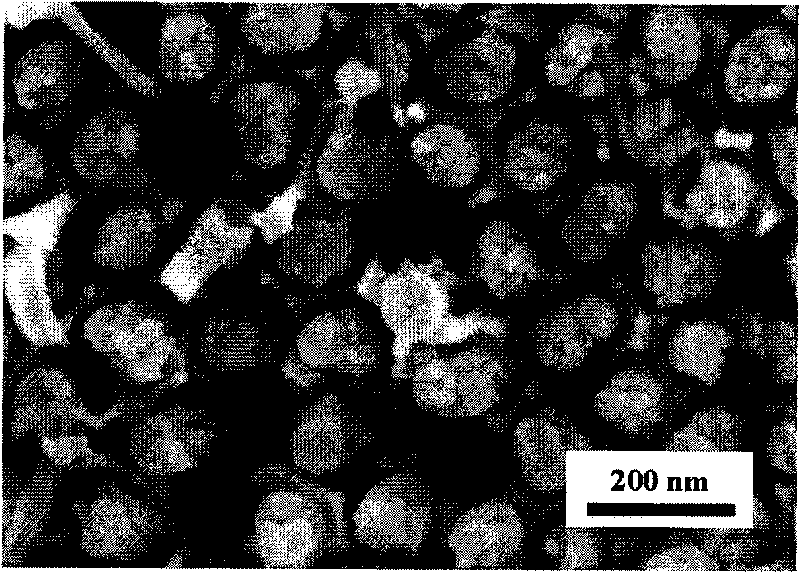

[0027] Embodiment 1, preparation copper indium selenium nanowire array

[0028] 1) With a silicon wafer with a thickness of 0.52 mm as the substrate, the Mo metal conductive layer was prepared by DC magnetron sputtering. The sputtering power was 120W, the sputtering pressure was 0.15Pa, and the sputtering time was 26 minutes. The thickness of the obtained Mo layer was 800nm.

[0029] 2) The Mo metal conductive layer covered with an ordered nano-template with a pore diameter of 50 nanometers, a distance between adjacent holes of 120 nanometers, and a thickness of 1200 nanometers is used as the cathode, and the material constituting the organic nano-template is an anodized aluminum template. The platinum sheet is the anode, and the saturated calomel electrode is the reference electrode, containing Cu 2+ 、In 3+ 、Se 4+ and Cl - , SO 4 2- Ionic aqueous solution as electrolyte solution, Cu 2+ 、In 3+ and Se 4+ The concentrations are 2 mmol / L, 2 mmol / L and 4 mmol / L respective...

Embodiment 2

[0032] Example 2, preparation of copper indium selenide nanowire array

[0033] 1) Using a silicon wafer with a thickness of 0.52 mm as the substrate, a W metal conductive layer was prepared by DC magnetron sputtering. The sputtering power was 120W, the sputtering pressure was 0.3Pa, and the sputtering time was 25 minutes. The thickness of the obtained W layer was 800nm.

[0034] 2) The W metal conductive layer covered with an ordered nano-template with a pore diameter of 90 nanometers, a distance between adjacent holes of 150 nanometers, and a thickness of 1600 nanometers is used as the cathode. The plate is the anode, and the saturated calomel electrode is the reference electrode, containing Cu 2+ 、In 3+ 、Se 4+ and Cl - , SO 4 2- An aqueous solution of ions is used as the electrolyte solution, Cu 2+ 、In 3+ and Se 4+ The concentrations are 5 mmol / L, 10 mmol / L and 10 mmol / L respectively, the control voltage is -0.6 volts, electrodeposited at room temperature for 20 mi...

Embodiment 3

[0037] Example 3, preparation of copper indium selenide nanowire array

[0038] 1) With a glass sheet with a thickness of 1.2 mm as the substrate, the Mo metal conductive layer was prepared by DC magnetron sputtering. The sputtering power was 80W, the sputtering pressure was 1.4Pa, and the sputtering time was 20 minutes. The thickness of the obtained Mo layer was 800nm.

[0039] 2) The Mo metal conductive layer covered with an ordered nano-template with a pore diameter of 90 nanometers, a distance between adjacent holes of 150 nanometers, and a thickness of 1600 nanometers is used as the cathode, and the material constituting the organic nano-template is an anodized aluminum template. The platinum sheet is the anode, and the saturated calomel electrode is the reference electrode, containing Cu 2+ 、In 3+ 、Se 4+ and Cl - , SO 4 2- Ionic aqueous solution as electrolyte solution, Cu 2+ 、In 3+ and Se 4+ The concentrations are 10 mmol / L, 10 mmol / L and 15 mmol / L respectively...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com