Process for producing isophthalic acid

A technology of isophthalic acid and m-xylene, which is applied in the direction of carboxylate preparation, organic compound preparation, organic compound/hydride/coordination complex catalyst, etc., can solve the problem of long residence time, increased device construction cost, Reduce the combustion reaction rate, minimize environmental pollution, and reduce equipment corrosion due to problems such as rising production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

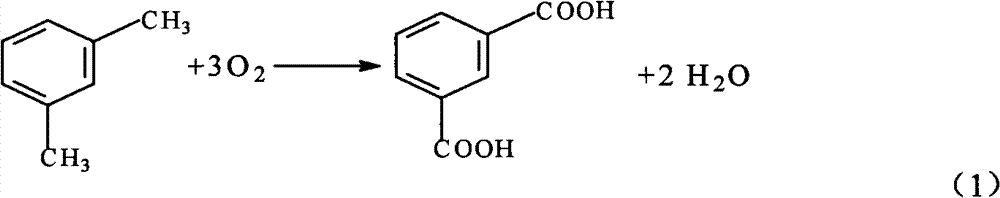

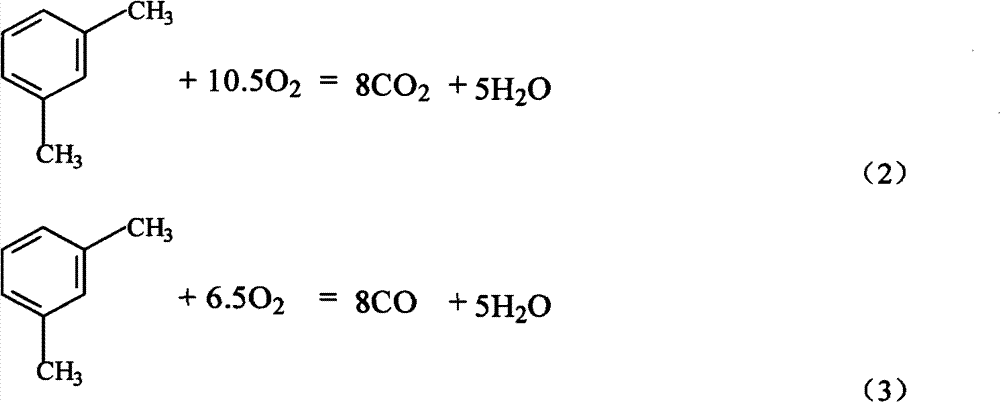

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] The coconut shell gac of 15g is soaked in the phosphomolybdovanadic acid (H 6 PMo 9 V 3 O 40 ·5H 2 O) in an aqueous solution, heated to reflux for 6 hours, filtered, washed with hot water until neutral, drained, dried at 110°C for 4 hours, then activated at 350°C for 12 hours under the protection of nitrogen to obtain a loading capacity of 10% (weight) of H 6 PMo 9 V 3 O 40 / C Catalyst.

[0034] The experiment was carried out in a stirred reactor with a volume of 1000ml, adding 400ml of glacial acetic acid, 50g of water, 25g of m-xylene, 5g of the previously prepared 40-60 mesh activated carbon supported heteropolyacid catalyst, the reaction temperature was 210°C, and the pressure was 13MPa. The flow rate of air is 1 L / min, the reaction is 30 minutes, the conversion rate of m-xylene is 100%, and the yield of isophthalic acid reaches 95%.

Embodiment 2

[0036] The preparation method of activated carbon-supported heteropolyacid catalyst is as in Example 1.

[0037] The experiment was carried out in a fixed-bed reactor with a height of 80 cm and an inner diameter of 2 cm, which contained 10-20 meshes of activated carbon-loaded heteropolyacid catalysts. The gas-liquid two-phase flowed through the reactor from bottom to top, and the flow rate of the liquid was 10ml / min. The flow rate of air 500ml / min, in the liquid feed, m-xylene 15% (weight), water 20% (weight), all the other are acetic acid, 210 ℃ of reaction temperatures, pressure 13MPa, m-xylene conversion rate 50%, m-xylene Diformic acid yield reached 49%.

Embodiment 3

[0039] 15g of coal-based activated carbon was immersed in 20% phosphotungstic acid (H 3 PW 12 O 40 ) in an aqueous solution, heated to reflux for 4 hours, filtered, washed with hot water until neutral, drained, dried at 110°C for 5 hours, and activated at 300°C for 10 hours under the protection of nitrogen to obtain a loading capacity of 15 % (weight) of H 3 PW 12 O 40 / C catalyst.

[0040] Experimental research was carried out under the same conditions as in Example 1. After 35 minutes of reaction, the conversion rate of m-xylene was 100%, and the yield of isophthalic acid reached 94%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com