Xylanase/cellobiase composite enzyme and preparation method thereof

A technology of cellobiase and xylanase, applied in the biological field, can solve the problems of lack of cellobiase, affecting the degradation rate of cellulose, etc., and achieve the effect of solving environmental pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

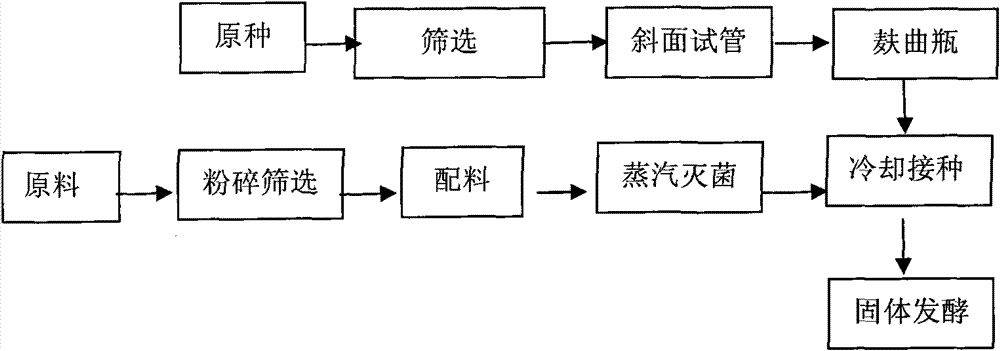

Method used

Image

Examples

Embodiment 1

[0029] Select the slant of the Aspergillus niger CGMCC3.3147 strain that grows well, gently pick the slant spores and insert them into the bran bottle of the medium containing 20% bran and 70% corn stalks, put a cotton plug on it and wrap it with kraft paper. Shake the glutinous gluten bottle to disperse the spores evenly in the culture medium, move the gluten gluten bottle to the culture room, and cultivate it at 27°C. After culturing to the 10th day, the spores were completely covered with the whole culture medium and then moved into the refrigerator for later use.

[0030] The composition of the solid fermentation medium is 20% bran, 70% corn stalks, 1% urea, 0.2% ammonium sulfate, 0.03% potassium dihydrogen phosphate, 0.002% magnesium sulfate, 0.0001% cobalt chloride, the balance of water, the initial pH5 .6.

[0031] After adding water, stir evenly, and the water content is 65%. Fill the solid medium into a shallow dish and autoclave at 121°C for 60 minutes. Pour ste...

Embodiment 2

[0034] Select the slant of the Aspergillus niger CGMCC3.3147 strain that grows well, gently pick the spores of the slant and insert it into a bran bottle containing 20% bran and 70% wheat straw medium, plug it with a cotton plug and wrap it with kraft paper, shake vigorously Homogenize the bran koji bottle to disperse the spores evenly in the culture medium, move the bran koji bottle to the culture room, and cultivate it at 28°C. After cultivating to the 7th day, the spores were completely covered with the whole culture medium and then moved into the cold room for later use.

[0035] The composition of the solid medium is 20% bran, 70% wheat straw, 1.5% urea, 0.2% ammonium sulfate, 0.04% potassium dihydrogen phosphate, 0.003% magnesium sulfate, 0.0002% cobalt chloride, the balance is water, and the initial pH is 5. 6. After adding water, stir evenly, and the water content is 70%.

[0036] Fill the solid medium into a shallow dish and autoclave at 121°C for 60 minutes. Pou...

Embodiment 3

[0038] Select the slant of the Aspergillus niger CGMCC3.3147 strain that grows well, gently pick the slant spores and insert them into a bran bottle containing 30% bran and 60% straw medium, put a cotton plug on it and wrap it with kraft paper, shake vigorously The bran koji bottle can disperse the spores evenly in the culture medium, and the bran koji bottle is moved to the culture room, and cultured at 27°C. After culturing to the 10th day, the spores were completely covered with the whole culture medium and then moved into the refrigerator for later use.

[0039]The composition of the solid medium is 30% bran, 60% straw, 2.0% urea, 0.1% ammonium sulfate, 0.04% potassium dihydrogen phosphate, 0.003% magnesium sulfate, 0.0005% cobalt chloride, the balance is water, and the initial pH is 6.0 .

[0040] After adding water, stir evenly, and the water content is 75%. Fill the solid medium into a shallow dish and autoclave at 121°C for 60 minutes. Pour sterilized water into the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com