Electrochemically deposited manganese dioxide reference electrode of and preparation method thereof

A manganese dioxide electrode, manganese dioxide ginseng technology, applied in scientific instruments, measuring devices, instruments, etc., can solve the problems of high price, high raw material requirements, poor potential reproducibility, etc., to ensure service life and long-term durability , The effect of simple preparation operation and low electrode cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

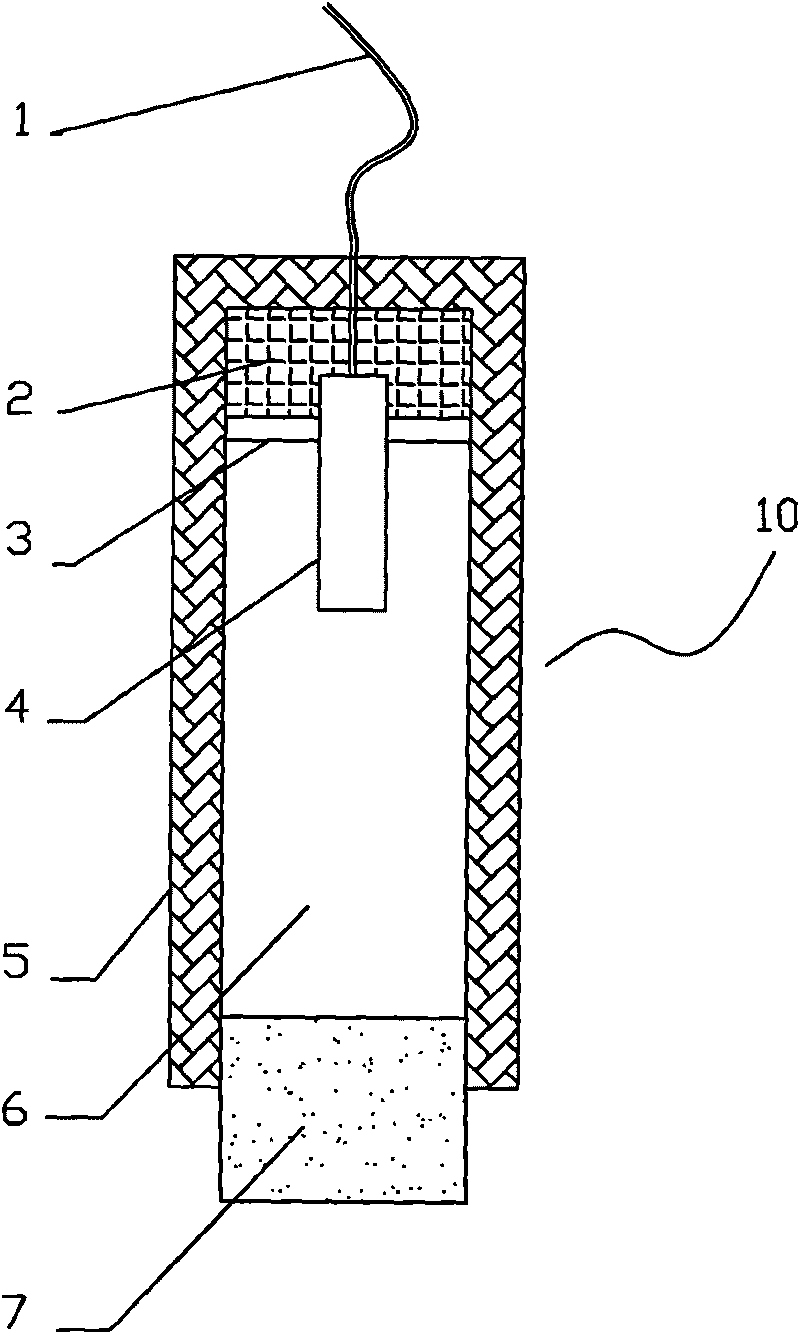

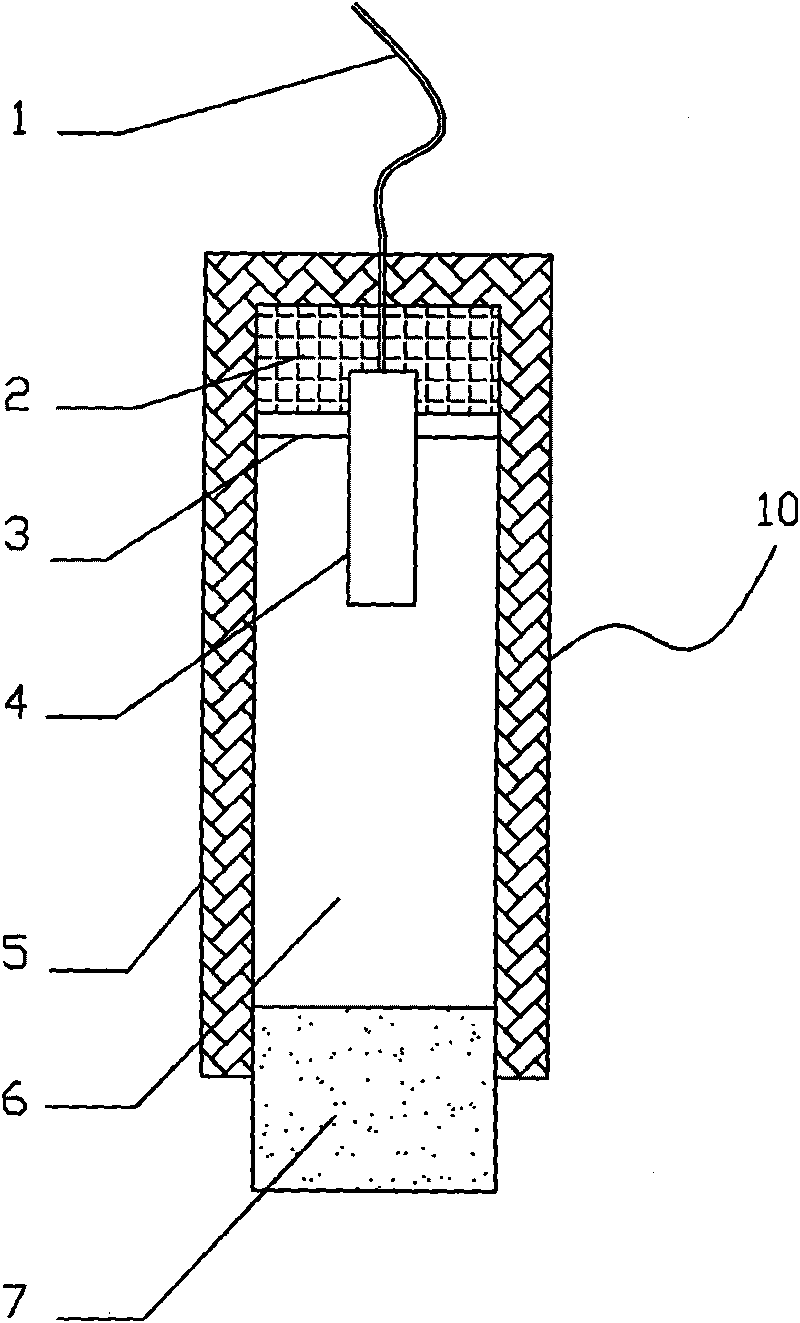

Image

Examples

Embodiment 1

[0023] A TA1-grade titanium metal cylinder is selected as the valve metal substrate, firstly polished step by step with 300-mesh and 600-mesh SiC sandpaper, and then sandblasted and soaked in oxalic acid solution with a concentration of 10% at 90°C for 2 hours to form a relatively Low resistivity and more microporous interlayer.

[0024] The manganese dioxide deposition layer is deposited on the above-mentioned treated titanium substrate by electrodeposition, the deposition solution is 0.5mol / L manganese acetate solution, and the constant potential polarization is adopted, and the reference electrode is a saturated calomel electrode. After electroplating at room temperature for 3 hours, a manganese dioxide deposition layer is formed on the titanium metal substrate. The above-mentioned electrode core was installed according to the preparation process of the reference electrode to obtain an electrochemically deposited manganese dioxide reference electrode, and its potential was ...

Embodiment 2

[0026] A titanium-nickel alloy cylinder is selected as the substrate, firstly polished step by step with 300-mesh and 600-mesh SiC sandpaper, then sandblasted and soaked in oxalic acid solution with a concentration of 20% at 90°C for 1 hour to form a low resistance Rate and more microporous middle layer.

[0027] Electrodeposition is used to deposit manganese dioxide deposition layer on the above-mentioned treated titanium metal substrate, and the deposition solution is selected as 0.8mol / LMnSO 4 with 0.3mol / LH 2 SO 4 The mixed liquid of the solution adopts the method of constant current polarization, and the polarization current density is 10mA / cm 2 , a saturated calomel electrode was used as the reference electrode, electroplating at room temperature for 1 h, and a manganese dioxide deposition layer was formed on the titanium metal substrate. The above-mentioned electrode core body is installed according to the reference electrode preparation process to obtain an electroc...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com