A silicon-based field emission cathode material with low threshold electric field and its preparation method

The invention relates to a field emission cathode and a technology for emitting the cathode, which is applied to the cathode of a field emission flat panel display. , Silicon-based semiconductor thin film materials and their preparation, the field of semiconductor nano-film surface morphology and orientation and crystallinity control, can solve the problems of complex emission cathode preparation process, low emission current density, poor emission stability, etc., and achieve great commercial application potential, The preparation process is simple and easy, and the effect of high emission current density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

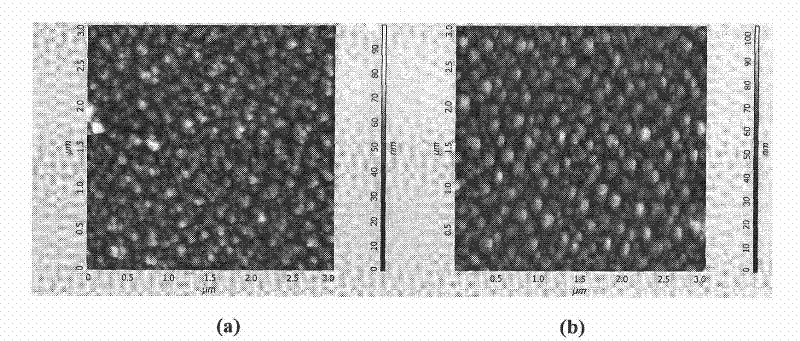

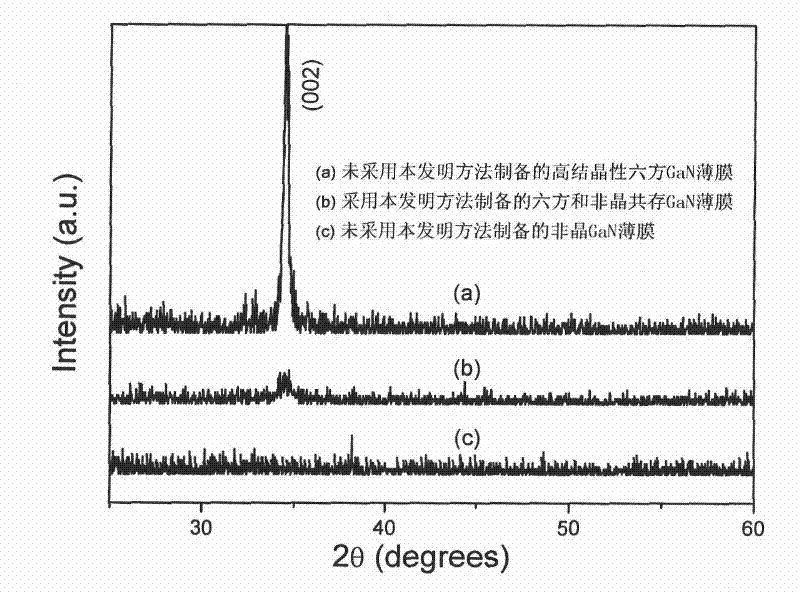

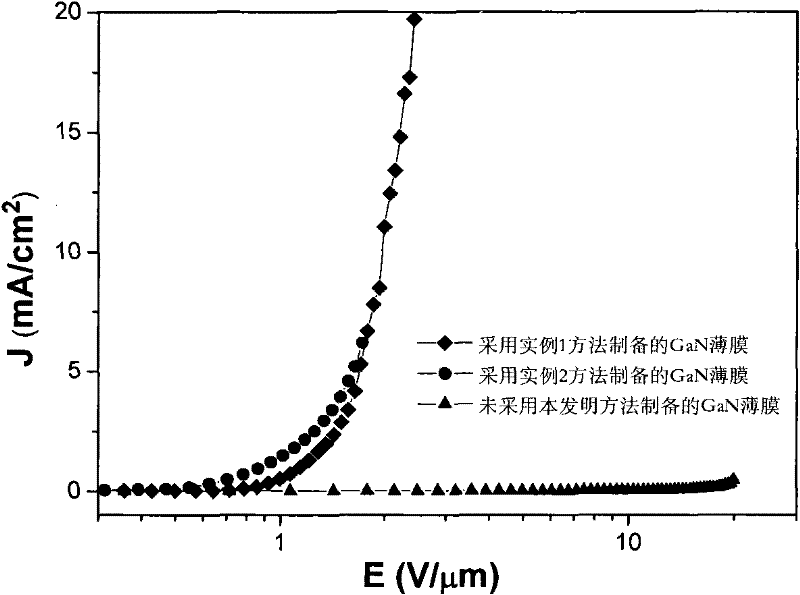

[0033] The polished n-type (100) silicon was soaked in HF acid with a volume concentration of 3% for 2 minutes as the substrate, and the gallium nitride powder with a purity of 99.99% was sintered at 560°C for 120 minutes to make a gallium nitride target, and the substrate and target were placed in In the cavity of the laser pulse deposition system, the deposition chamber is pumped to about 5×10 -4 Pa, and heat the silicon substrate to 850°C, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, set the frequency of the pulse laser to 13Hz, and start to deposit hexagonal ( 002) The gallium nitride thin film with preferred orientation and amorphous phase coexists, and the average thickness of the thin film reaches 40nm after maintaining for 2 minutes. The field emission current density is 1mA / cm 2 , the required applied electric field strength is 1.2V / μm.

Embodiment 2

[0035] The polished n-type (100) silicon was soaked in HF acid with a volume concentration of 3% for 2 minutes as the substrate, and the gallium nitride powder with a purity of 99.99% was sintered at 560°C for 120 minutes to make a gallium nitride target, and the substrate and target were placed in In the cavity of the laser pulse deposition system, the deposition chamber is pumped to about 5×10 -4 Pa, and heat the silicon substrate to 850°C, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 1Pa, set the frequency of the pulse laser to 13Hz, and start to deposit hexagonal ( 002) GaN thin film with preferred orientation and amorphous phase coexistence, maintain the time for 1.5min to make the average thickness of the thin film reach 30nm. The field emission current density is 1mA / cm 2 , the required applied electric field strength is 0.9V / μm.

Embodiment 3

[0037]The polished n-type (100) silicon was soaked in HF acid with a volume concentration of 3% for 2 minutes as the substrate, and the aluminum nitride powder with a purity of 98% was sintered at 560°C for 120 minutes to make an aluminum nitride target, and the substrate and target were placed in In the cavity of the laser pulse deposition system, the deposition chamber is pumped to about 1×10 -4 Pa, and heat the silicon substrate to 900°C, supply nitrogen with a purity of 99.99% as a protective gas and adjust the working pressure of the deposition chamber to 0.5Pa, set the frequency of the pulse laser to 12Hz, and the pulse energy to 350mJ / pulse and start to deposit hexagonal (002) AlN thin film with preferred orientation and amorphous phase coexistence, maintain the time for 1.5min to make the average thickness of the film reach 25nm. The field emission current density is 1mA / cm 2 , the required applied electric field strength is 2.1V / μm.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com