Liquid crystal aligning agent, liquid crystal aligning film, method for forming the same, and liquid crystal display element

A technology of liquid crystal alignment agent and carbon number, which is applied in the direction of instruments, optics, nonlinear optics, etc., and can solve the problem of large radiation dose

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Synthetic example 1

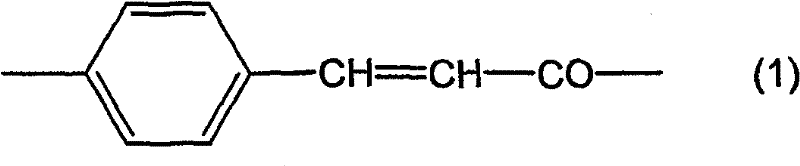

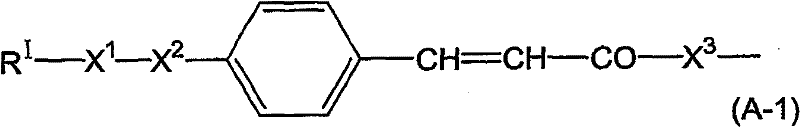

[0225] Synthesis Example 1 (Synthesis of Compound (A-1-2-1))

[0226] Compound (A-1-2-1) was synthesized according to the following Synthetic Scheme 1.

[0227]

[0228] Synthetic route 1

[0229] Add 82g of p-hydroxycinnamic acid, 304g of potassium carbonate and 400ml of N-methyl-2-pyrrolidone in a 1L eggplant-shaped flask. After stirring for 1 hour at room temperature, add 166g of 1-bromopentane and stir at 100°C for 5 Hour. Then, the solvent was distilled off under reduced pressure. Then add 48g of sodium hydroxide and 400ml of water therein, and reflux for 3 hours to carry out the hydrolysis reaction. After the reaction, the reaction system was neutralized with hydrochloric acid, and the resulting precipitate was recovered and recrystallized with ethanol to obtain 80 g of white crystals of a compound represented by the following formula (A-1-2-1).

Synthetic example 2

[0230] Synthesis Example 2 (Synthesis of Compound (A-1-2-2))

[0231] In the above synthesis example 1, except that 262 g of 1-iodo-4,4,4-trifluorobutane was used instead of 1-bromopentane, the same procedure was carried out as in synthesis example 2 to obtain 85 g of the following formula (A-1- 2-2) White powder of the compound (compound (A-1-2-2)).

[0232]

Synthetic example 3

[0233] Synthesis Example 3 (Synthesis of Compound (A-1-4-1))

[0234] Compound (A-1-4-1) was synthesized according to the following Synthetic Scheme 2.

[0235]

[0236] Synthetic route 2

[0237] (Synthesis of compound (A-1-4-1A))

[0238] Add 91.3g methyl 4-hydroxybenzoate, 182.4g potassium carbonate and 320ml N-methyl-2-pyrrolidone to a 1L eggplant-shaped flask, stir at room temperature for 1 hour, then add 99.7g 1-bromopentane , and stirred at 100° C. for 5 hours to react. After the reaction, reprecipitation was performed with water. Then, 48 g of sodium hydroxide and 400 ml of water were added to the precipitate, and the hydrolysis reaction was carried out by refluxing for 3 hours. After completion of the reaction, it was neutralized with hydrochloric acid, and the resulting precipitate was recrystallized with ethanol to obtain 102 g of white crystals of compound (A-1-4-1A).

[0239] (Synthesis of compound (A-1-4-1))

[0240] 52 g of this compound (A-1-4-1A) wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

| Solution viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com