Method, device and system for removing aflatoxin

A kind of aflatoxin and ultraviolet technology, applied in the fields of application, food preparation, food science, etc., can solve the problems of affecting the flavor and quality of oil, high local temperature of the lamp tube, low energy utilization rate, etc., and achieve high energy utilization efficiency and light source The effect of low power and the need to cool the device

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 example

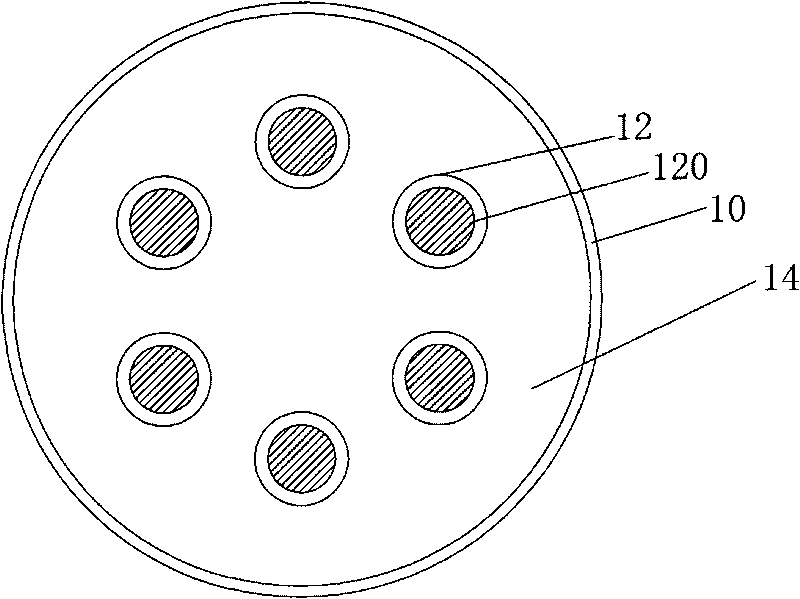

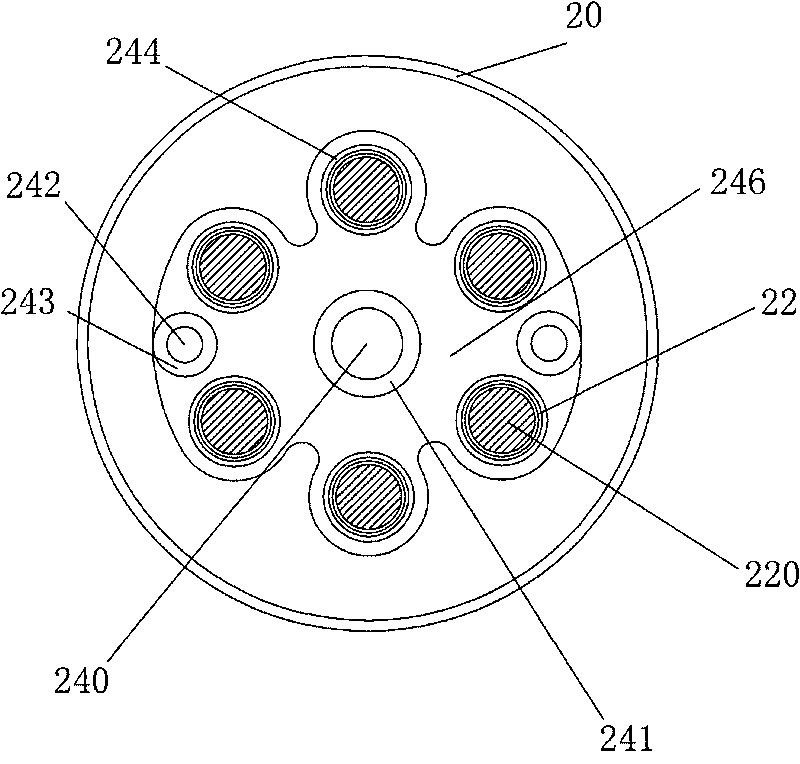

[0058] figure 1 A first embodiment of the device for removing aflatoxin of the present invention is shown. See figure 1 , the device includes a food-grade stainless steel cylindrical shell 10 and six quartz glass lamp tubes 12 installed inside the shell. One end of the cylindrical casing 10 is used as an inlet for food oil, and the other end is used as an outlet for food oil. Each quartz glass lamp tube 12 is equipped with a single-wavelength ultraviolet light source 120. The wavelength of the single-wavelength ultraviolet light source 120 can be any value between 355nm and 375nm, preferably 365nm. Between the cylindrical shell 10 and the quartz glass lamp tube 12 is an airtight interlayer 14, the food oil flows in the airtight interlayer 14, and the single-wavelength ultraviolet light source 120 irradiates the food oil in the interlayer 14 by ultraviolet irradiation, so that the food oil The aflatoxin in is decomposed.

[0059] In addition to meeting the above wavelength ...

no. 2 example

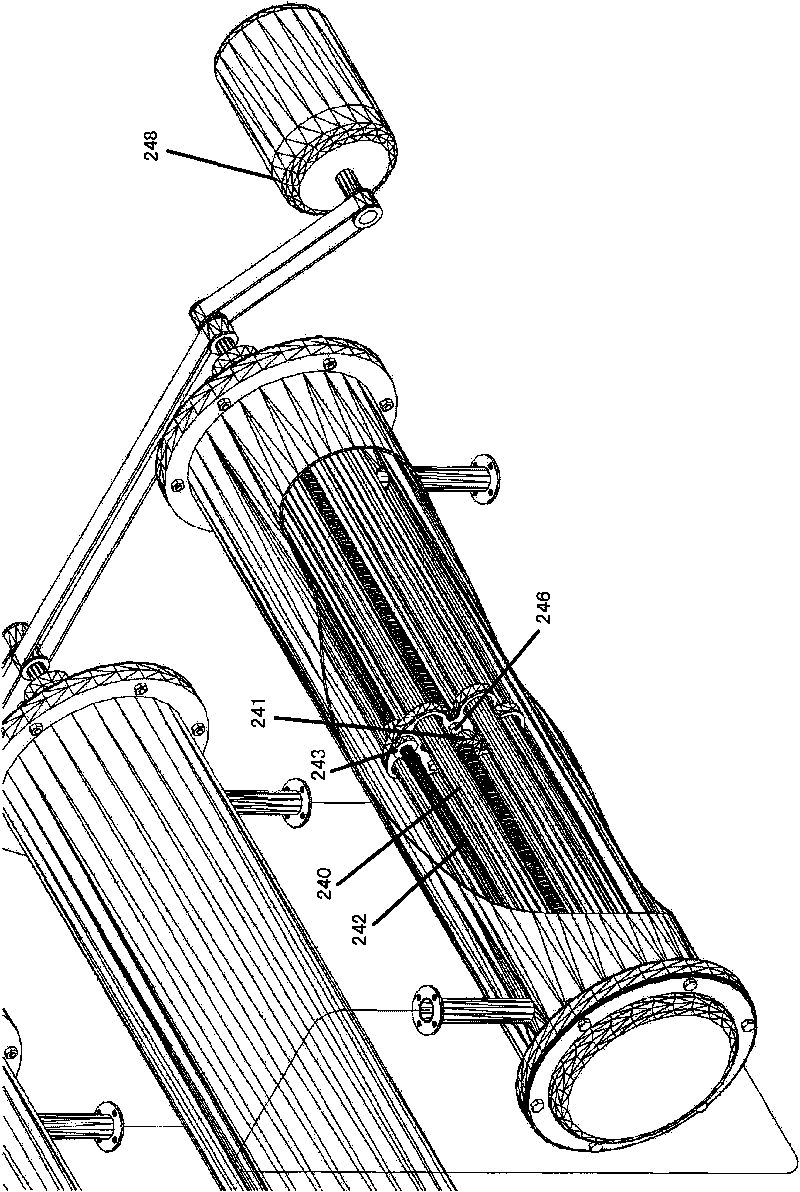

[0071] Figure 5 A second embodiment of the aflatoxin removal system of the present invention is shown. See Figure 5 , the system is composed of multiple irradiation units 40 connected in parallel, and also includes a transmission system 41 connecting each irradiation unit 40 , a power system 42 and a control cabinet 43 , and the control cabinet 43 is used to control the output of the power system 42 . The irradiation unit 40 may be as figure 2 The shown device for removing aflatoxin can also be as image 3Shown is an aflatoxin removal device incorporating an automatic wipe assembly.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com