Method for preparing core-shell structure composite material by Gamma-ray irradiation

A technology of composite materials and γ-rays, which is applied in the field of preparation of core-shell structure composite materials, can solve the problems of many steps, inability to remove, and easy introduction of by-products by reducing agents, so as to avoid agglomeration, easy to remove, and improve magnetic properties. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

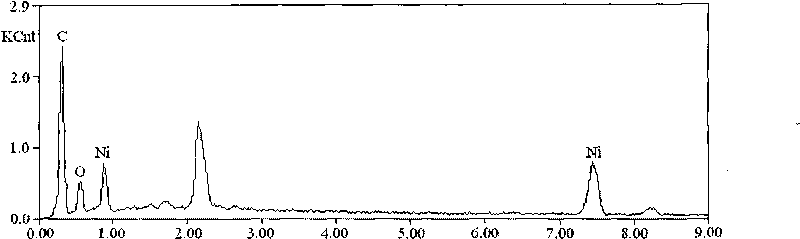

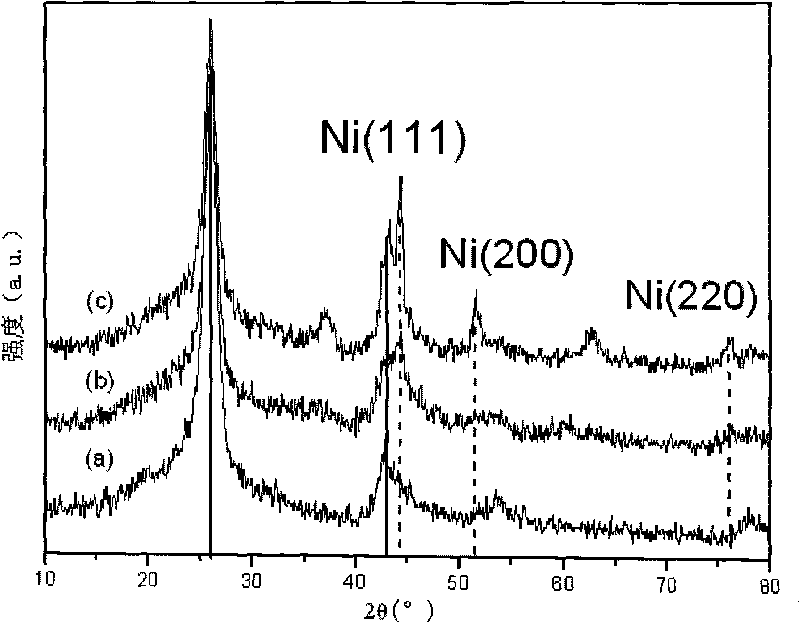

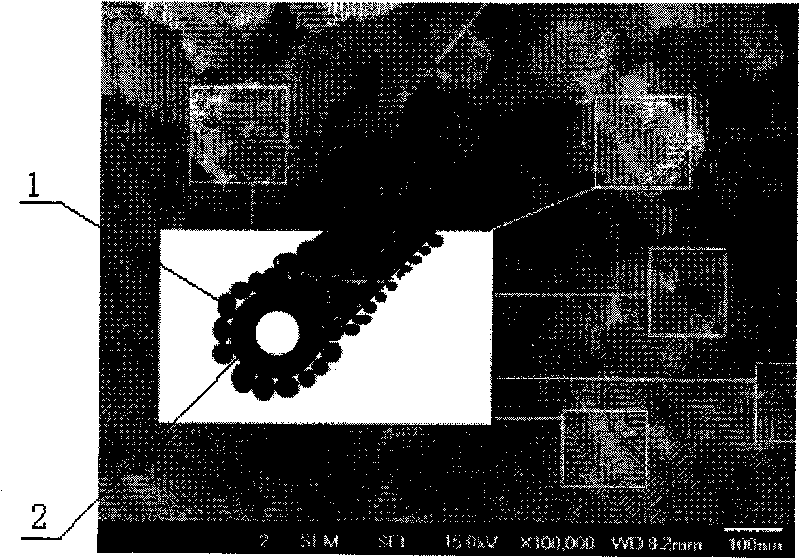

[0018] Specific embodiment one: the method for preparing the core-shell structure composite material by gamma ray irradiation in this embodiment is characterized in that the method for preparing the core-shell structure composite material by gamma ray irradiation is completed by the following steps: 1. Purify nanomaterials or micron materials, then add them to the metal salt solution, then add free radical scavengers, adjust the pH value to 10, and ultrasonically disperse for 30-60 minutes; 60 Co is the γ-ray irradiation of the irradiation source, and the irradiation dose is 1×10 3 ~1×10 5 Gy, radiation dose rate 1~1×10 3 Gy / min, then washed with ammonia water, distilled water and ethanol in turn, then centrifuged, and vacuum dried at 50-80°C for 2 hours to obtain a core-shell structure nano / micro composite material; the nanomaterial or micron material in step 1 The mass ratio to metal ions is 10-1:1.

[0019] In step 1 of this embodiment, 1-10 moles of free radical scaveng...

specific Embodiment approach 2

[0021] Specific embodiment 2: The difference between this embodiment and specific embodiment 1 is: after vacuum drying in step 2, recrystallization is carried out for 3-8 hours under the condition of 600-800° C. with an inert gas as a protective gas; Core-shell structured nano / microcomposites. Other reaction steps and parameters are the same as in Embodiment 1.

[0022] The inert gas described in this embodiment is nitrogen or argon.

specific Embodiment approach 3

[0023] Embodiment 3: This embodiment is different from Embodiment 2 in that: the recrystallization is carried out for 5-7 hours under the condition of 650-750° C. with an inert gas as the protective gas.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com