Functionalized nano-fiber heavy metal ion adsorbing material and preparation method thereof

A technology of heavy metal ions and nanofibers, which is applied in chemical instruments and methods, and other chemical processes, can solve problems such as difficult to efficiently adsorb and enrich samples with small volumes and large particle sizes, and achieve simple and safe preparation methods with low usage volume. The effect of small, large specific surface area

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0034] Preparation and adsorption performance experiment of the functionalized polystyrene nanofiber adsorbent of embodiment 1

[0035] Add polystyrene into an appropriate amount of N,N-dimethylformamide-tetrahydrofuran (4:6) mixed solvent to make the mass volume fraction 10%, stir until dissolved, then add an appropriate amount of dithizone to make bis The mass fraction of thizone in the spinning solution reaches 0.25%-0.5%. After the dithizone is dissolved, the stirring is continued for a period of time.

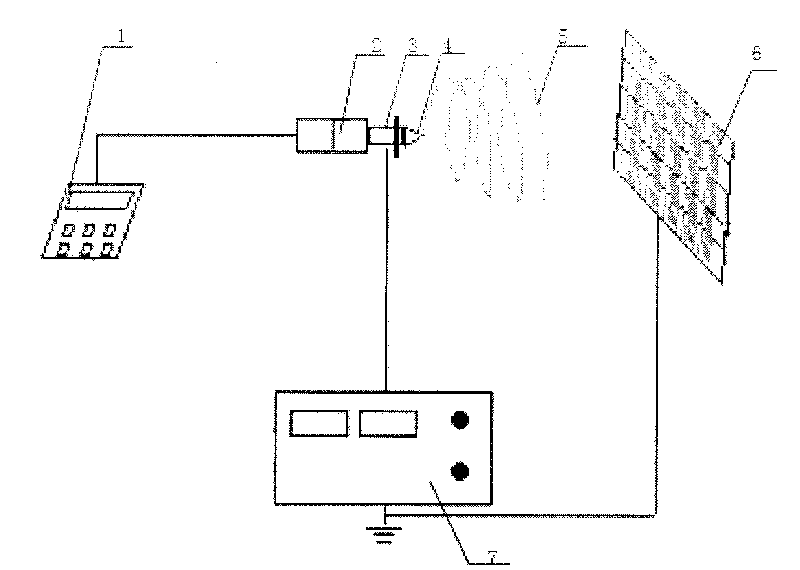

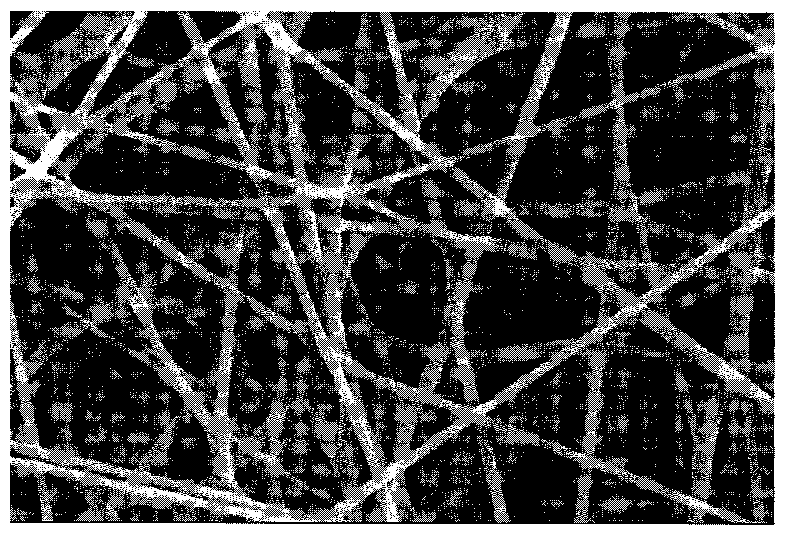

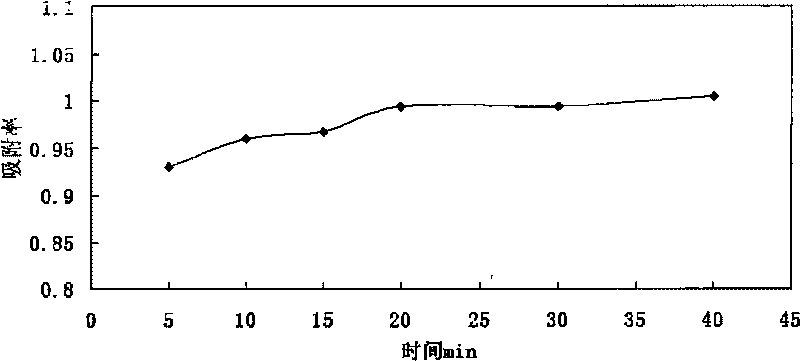

[0036] The functionalized polystyrene solution was spun into nanofibers using an electrospinning device. Electrospinning device such as figure 1As shown, the polymer solution 2 is sucked into the glass syringe equipped with the injection needle 3 by the propeller 1 (which can have a metering device), the injection voltage is 14-18kV, the propeller speed is 0.5-1mL / h, and the injection needle 3 The distance from the receiving device 6 is 20-30 cm, apply enough voltage bet...

Embodiment 2

[0038] Example 2 Preparation and adsorption performance experiment of functionalized styrene-methacrylic acid copolymer nanofiber adsorbent

[0039] Add styrene-methacrylic acid copolymer into an appropriate amount of N,N-dimethylformamide-tetrahydrofuran (4:6) mixed solvent to make the mass volume fraction 10%, stir until dissolved, then add an appropriate amount of Catechol violet, so that the mass volume fraction of catechol violet in the spinning solution reaches 0.4%, and after the catechol violet is dissolved, continue stirring for a period of time.

[0040] The functionalized styrene-methacrylic acid copolymer solution was spun into nanofibers using an electrospinning device. The electrospinning device is the same as in Example 1 to obtain nanofibers with diameters ranging from nanometers to submicrometers.

[0041] Weigh about 2.5 mg of nanofibers, activate with 2 mL of 70% methanol for 3 minutes, rinse with 3 mL of 10% methanol, put them into a centrifuge tube filled...

Embodiment 3

[0042] Example 3 Preparation and adsorption performance experiment of functionalized polystyrene-acrylic resin mixed nanofiber adsorbent

[0043] Add polystyrene and acrylic resin to an appropriate amount of N, N-dimethylformamide-tetrahydrofuran (4:6) mixed solvent, so that the mass volume fraction is 5%, stir until dissolved, and then add an appropriate amount of disulfide Hydrazone, so that the mass volume fraction of dithizone in the spinning solution reaches 0.3%, and after the dithizone is dissolved, continue stirring for a period of time.

[0044] The functionalized polystyrene-acrylic resin mixed solution was spun into nanofibers using an electrospinning device. The electrospinning device is the same as in Example 1 to obtain nanofibers with diameters ranging from nanometers to submicrometers.

[0045] Weigh about 2.5 mg of nanofibers, activate with 2 mL of 70% methanol for 3 minutes, rinse with 3 mL of 10% methanol, put them into a centrifuge tube filled with 1.5 mL ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com