Method for producing high-purity glabridin

A glabridin, high-purity technology, applied in organic chemistry and other directions, can solve problems such as difficulty in achieving purity, and achieve the effects of improved yield, good solubility, and high product safety.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

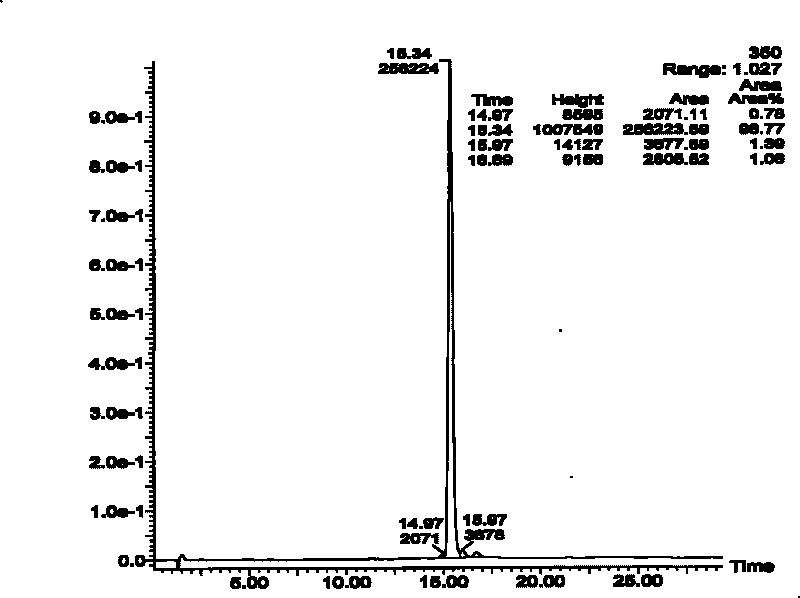

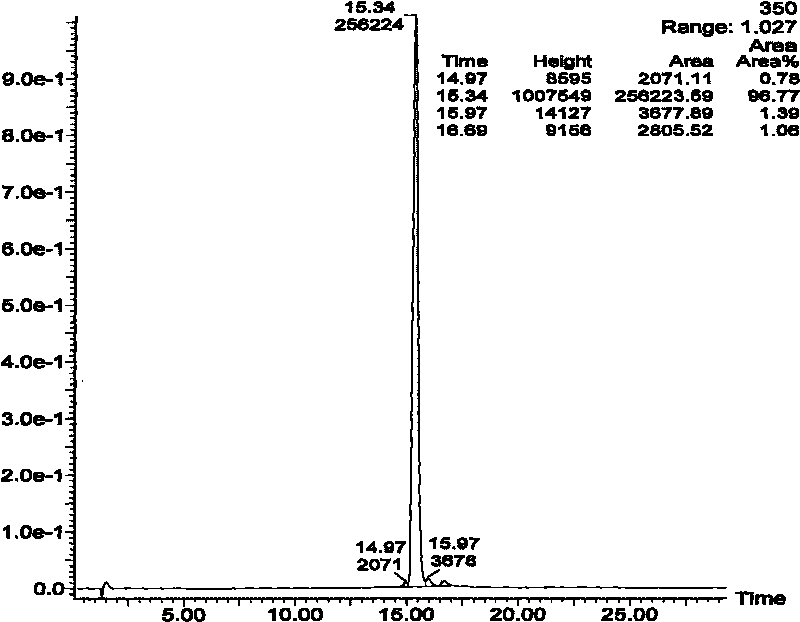

Image

Examples

Embodiment 1

[0029] (1) Glycyrrhiza glabra (collected from Xinjiang) was dried and crushed, and 1kg of powder passed through a 20-mesh sieve was taken, placed in a 10L stainless steel pot, decocted and extracted with 4L ammonia water of pH 8, boiled and stirred for 1 hour, and extracted twice in total, Centrifuge to remove the residue; combine the extracts and concentrate to 1L to obtain the concentrated ammonia solution;

[0030] (2) Put the ammonia water concentrate obtained in step (1) on the macroporous adsorption resin (AB-8, produced by Nankai University Chemical Factory) chromatography column (Φ60×600mm), after elution with 1500ml water, continue to use 2000ml volume percentage concentration For 45% ethanol elution, collect eluent, concentrate to dryness, obtain purity and be 56.02% glycyrrhizic acid, deposit; Continue to use 2000ml volume percent concentration as 95% ethanol elution, collect eluent, concentrate to 250ml, obtain a concentrate;

[0031] (3) Go up polyamide (Zhejiang...

Embodiment 2

[0035] (1) Get 10kg of Glycyrrhiza glabra (collected from Xinjiang) powder with a 20-mesh sieve, put it in a 100L reaction kettle, boil and stir for 1 hour with 50L of pH8.5 sodium hydroxide alkaline aqueous solution, and extract 3 times in total. Centrifuge to remove the residue; combine the extracts and concentrate to 15L to obtain the sodium hydroxide concentrate;

[0036] (2) Put the sodium hydroxide concentrated solution on the macroporous adsorption resin (X-5, produced by Nankai University Chemical Factory) chromatography column (Φ100×1500mm), after elution with 12L water, continue to use 20L volume percentage concentration to be 55% ethanol elution, collect the eluent, concentrate to dryness, and obtain glycyrrhizic acid with a purity of 63.55%, store it; continue to elute with 20L volume percentage concentration of 85% ethanol, collect the eluate, concentrate to 3L, and obtain a concentrated solution ;

[0037] (3) Put the 3L concentrated solution obtained in step (2...

Embodiment 3

[0041] (1) Get 50kg of Glycyrrhizae glabra (gathered from Xinjiang) powder 20 mesh sieves, place in a 500L multifunctional extraction tank, boil and stir for 2 hours with 250L pH9 potassium hydroxide alkali aqueous solution, extract 3 times altogether, Centrifuge to remove the residue; combine the extracts and concentrate to 80L to obtain potassium hydroxide concentrate;

[0042] (2) Put the concentrated solution of potassium hydroxide on a macroporous adsorption resin (AB-8, produced by Nankai University Chemical Factory) chromatography column (Φ300×1800mm), after eluting with 100L water, continue to use 200L volume percentage concentration of 50 % ethanol for elution, collect the eluent, concentrate to dryness, and obtain glycyrrhizic acid with a purity of 61.43%, store it; continue to elute with 200L volume percentage concentration of 90% ethanol, collect the eluate, concentrate to 30L, and obtain concentrated liquid;

[0043] (3) Add polyamide (produced by Zhejiang Taizho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com