Method for preparing immobilized glucose isomerase with composite magnetic chitosan microballoon spheres

A technology of glucose isomerase and composite microspheres, which is applied in the field of preparation of immobilized glucose isomerase by magnetic chitosan composite microspheres, can solve the problems of non-reusable use, waste, and low efficiency of glucose isomerase use, and achieve The effect of easy operation, lower production cost and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

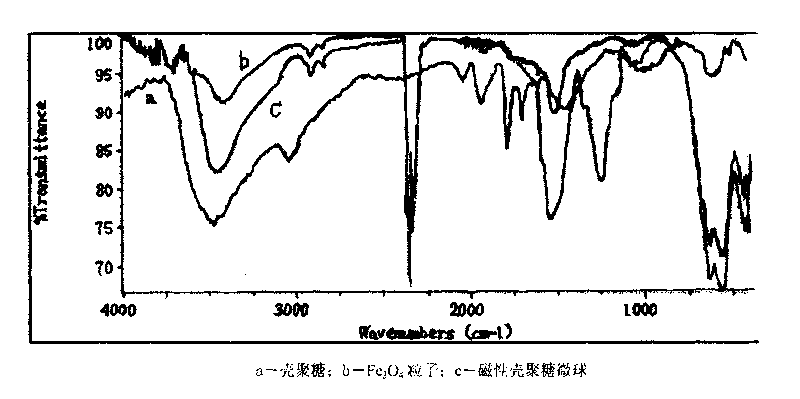

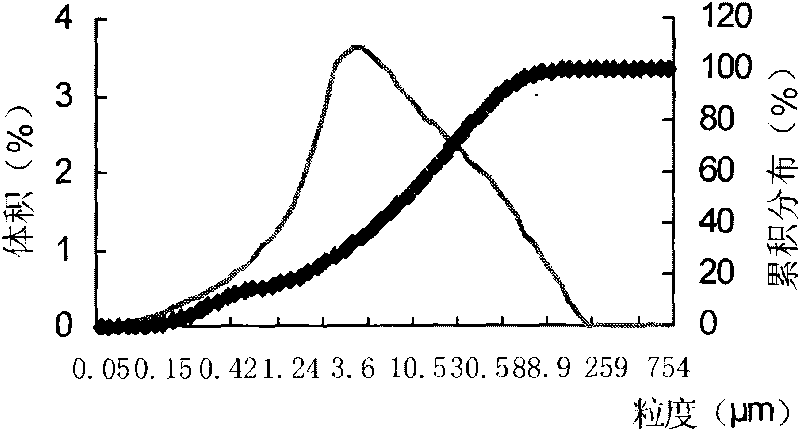

[0018] 1. To 0.4mol / L FeCl 2 100ml and FeCl 3 In 100ml, add 10.0g of polyglycol with a molecular weight of 4000, fully dissolve it under a magnetic stirrer, adjust the pH of the solution to 10 with ammonia water, continue to stir for 30min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0019] 2. Dissolve chitosan powder in 3% acetic acid and disperse ultrasonically for 10 minutes to prepare a 0.02g / ml chitosan solution. 3 o 4 Mix with magnetic nuclear ultrasound and electric stirring for 10 minutes to form a microemulsion system, and cross-link with 5% glutaraldehyde, continue stirring for 4 hours at 2000r / min, then wash with petroleum ether, acetone and double-distilled water, and vacuum After freeze-drying, the magnetic chitosan composite microspheres are obtained. The emulsifier consists of 60ml liquid paraffin, 1ml span-80, 1ml Tween-60, and 1ml n-butanol.

[0020] 3. Soak the prepared magnetic chitosan composite microsphe...

Embodiment 2

[0022] 1. To 0.5mol / L FeCl 2 30ml and FeCl 3 Add 6.0g of polyethylene glycol with a molecular weight of 4000 to 50ml, fully dissolve it under a magnetic stirrer, adjust the pH of the solution to 8 with ammonia water, continue to stir for 50min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0023] 2. Dissolve the chitosan powder in 6% acetic acid for 10 minutes of ultrasonic dispersion to make a 0.08g / ml chitosan solution, and pass the emulsifier and Fe 3 o 4 Ultrasonic disperse the magnetic nucleus and mix with electric stirring for 10 minutes to form a microemulsion system, and cross-link with 1% glutaraldehyde, continue stirring for 2 hours at 2000r / min, then wash with petroleum ether, acetone and double distilled water, and filter with suction The magnetic chitosan composite microspheres are obtained after vacuum freeze-drying.

[0024] 3. Soak the prepared magnetic chitosan composite microspheres with phosphate buffer pH 7....

Embodiment 3

[0026] 1. Using 0.6mol / L FeCl 2 30ml and FeCl 3 50ml, add 8.0g of polyethylene glycol with a molecular weight of 4000, fully dissolve under a magnetic stirrer, adjust the pH of the solution to 9 with ammonia water, continue to stir for 30min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0027] 2. Dissolve the chitosan powder in 5% acetic acid for 10 minutes of ultrasonic dispersion to make a 0.05g / ml chitosan solution, and pass the emulsifier and Fe 3 o 4 Mix with magnetic nuclear ultrasound and electric stirring for 10 minutes to form a microemulsion system, and cross-link with 2% glutaraldehyde, continue stirring for 2 hours at 2000r / min, then wash with petroleum ether, acetone and double-distilled water, filter and vacuum After freeze-drying, the magnetic chitosan composite microspheres are obtained. Wherein the emulsifier consists of 80ml liquid paraffin, 2.5ml span-80, 1.5ml Tween-60, and 2ml n-butanol.

[0028] 3. Soak ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com