Method for preparing immobilized glucose isomerase with composite magnetic chitosan microballoon spheres

A technology of glucose isomerase and composite microspheres is applied in the field of preparation of immobilized glucose isomerase by magnetic chitosan composite microspheres, which can solve the problems of inability to reuse, waste, and low utilization efficiency of glucose isomerase, etc. The effect of easy operation, lower production cost and increased yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

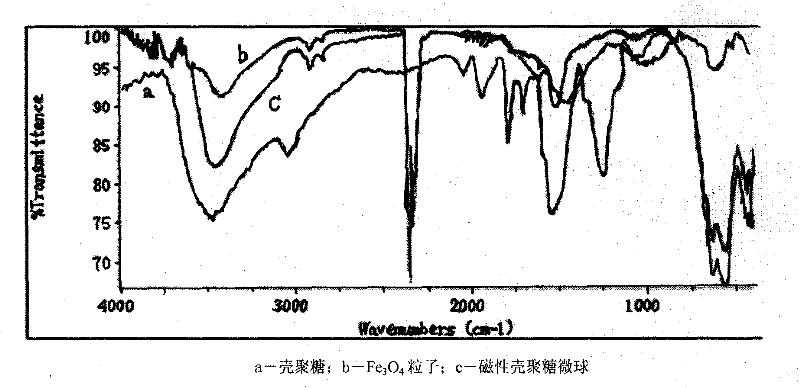

[0018] 1. To 0.4mol / L FeCl 2 100ml and FeCl 3 In 100ml, add 10.0g of polyglycol with a molecular weight of 4000, fully dissolve it under a magnetic stirrer, adjust the pH of the solution to 10 with ammonia water, continue to stir for 30min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0019] 2. Dissolve chitosan powder in 3% acetic acid and disperse ultrasonically for 10 minutes to prepare a 0.02g / ml chitosan solution. 3 o 4 Mix with magnetic nuclear ultrasound and electric stirring for 10 minutes to form a microemulsion system, and cross-link with 5% glutaraldehyde, continue stirring for 4 hours at 2000r / min, then wash with petroleum ether, acetone and double-distilled water, and vacuum After freeze-drying, the magnetic chitosan composite microspheres are obtained. The emulsifier consists of 60ml liquid paraffin, 1ml span-80, 1ml Tween-60, and 1ml n-butanol.

[0020] 3. Soak the prepared magnetic chitosan composite microsphe...

Embodiment 2

[0022] 1. To 0.5mol / L FeCl 2 30ml and FeCl 3 Add 6.0g of polyethylene glycol with a molecular weight of 4000 to 50ml, fully dissolve it under a magnetic stirrer, adjust the pH of the solution to 8 with ammonia water, continue to stir for 50min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0023] 2. Dissolve the chitosan powder in 6% acetic acid for 10 minutes of ultrasonic dispersion to make a 0.08g / ml chitosan solution, and pass the emulsifier and Fe 3 o 4 Ultrasonic disperse the magnetic nucleus and mix with electric stirring for 10 minutes to form a microemulsion system, and cross-link with 1% glutaraldehyde, continue stirring for 2 hours at 2000r / min, then wash with petroleum ether, acetone and double distilled water, and filter with suction The magnetic chitosan composite microspheres are obtained after vacuum freeze-drying.

[0024] 3. Soak the prepared magnetic chitosan composite microspheres with phosphate buffer pH 7....

Embodiment 3

[0026] 1. Using 0.6mol / L FeCl 2 30ml and FeCl 3 50ml, add 8.0g of polyethylene glycol with a molecular weight of 4000, fully dissolve under a magnetic stirrer, adjust the pH of the solution to 9 with ammonia water, continue to stir for 30min, wash with double distilled water and vacuum freeze-dry to obtain Fe 3 o 4 magnetic core.

[0027] 2. Dissolve the chitosan powder in 5% acetic acid for 10 minutes of ultrasonic dispersion to make a 0.05g / ml chitosan solution, and pass the emulsifier and Fe 3 o 4 Mix with magnetic nuclear ultrasound and electric stirring for 10 minutes to form a microemulsion system, and cross-link with 2% glutaraldehyde, continue stirring for 2 hours at 2000r / min, then wash with petroleum ether, acetone and double-distilled water, filter and vacuum After freeze-drying, the magnetic chitosan composite microspheres are obtained. Wherein the emulsifier consists of 80ml liquid paraffin, 2.5ml span-80, 1.5ml Tween-60, and 2ml n-butanol.

[0028] 3. Soak ...

PUM

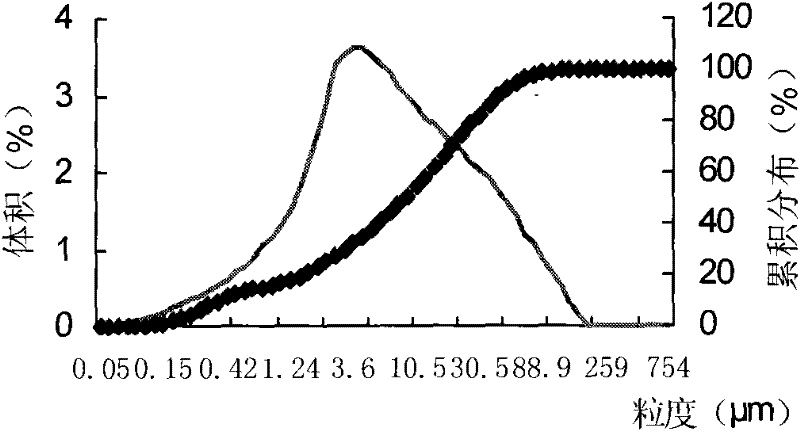

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com