Mixed type creep feed and preparation method thereof

A technology of creep feed and mixed type, applied in animal feed, animal feed, application, etc., can solve problems affecting pig farm production and economic benefits, and achieve the effects of improving the quality of weaning feed, reducing environmental pollution, and ensuring food safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

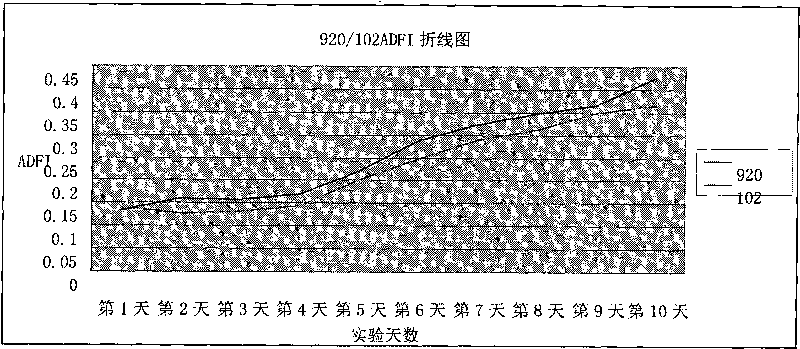

Image

Examples

Embodiment 1

[0027] The mixed creep material of this embodiment is formed by mixing granules and powder, wherein the weight ratio between the granules and powder is 70:30

[0028] Granules are prepared from the following raw materials in parts by weight:

[0029] Corn 40%, broken rice 5%, wheat 5%, barley 5%, puffed corn 5%, soybean meal (CP46) 5%, fermented soybean meal 3%, secondary flour 1%, spray-dried plasma protein powder 5%, steam fish meal 5% %, feed grade mixed oil 2%, whey powder 10%, lactose 10%, low-protein whey powder 5%, soybean protein isolate 6%, high-fat sweet whey 6%, astragalus polysaccharide 0.5%, methionine 0.05%, Lysine 0.1%, arginine 0.01%, feed small peptide 0.1%, soybean lecithin 0.2%, fat emulsifier 800ppm, fat powder 2-4%, ethoxyquinoline) 125ppm, dimethyl fumarate 500ppm, glutamine 0.2%, special compound enzyme for suckling pig 300ppm, vitamin A: 10000IU / kg, vitamin D 3 : 2000IU / kg, vitamin E: 40IU / kg, vitamin K 3 : 3mg / kg, vitamin B2: 5mg / kg, vitamin B6: 2mg...

Embodiment 2

[0040] The mixed creep material of this embodiment is formed by mixing granules and powder, wherein the weight ratio between the granules and powder is 70:30

[0041] Granules are prepared from the following raw materials in parts by weight:

[0042] Corn 10%, broken rice 30%, wheat 20%, barley 5%, puffed corn 10%, soybean meal 10%, fermented soybean meal 5%, secondary meal 2%, spray-dried plasma protein powder 3%, steam fish meal 3%, feed Grade mixed oil 2%, whey powder 5%, lactose 6%, high-fat sweet whey 6%, astragalus polysaccharide 1%, methionine 0.05%, lysine 0.3%, arginine 0.04%, feed small peptide 0.8% , soybean lecithin 0.6%, fat emulsifier 1000ppm, fat powder 3%, ethoxyquinoline 200ppm, dimethyl fumarate 1500ppm, glutamine 0.8%, suckling pig special compound enzyme 600ppm, vitamin A: 30000IU / kg, vitamin D 3 : 6000IU / kg, vitamin E: 90IU / kg, vitamin K 3 : 10mg / kg, vitamin B2: 15mg / kg, vitamin B6: 10mg / kg, vitamin B12: 60μg / kg, niacinamide: 90mg / kg, pantothenic acid:...

Embodiment 3

[0053] The mixed creep material of this embodiment is formed by mixing granules and powder, wherein the weight ratio between the granules and powder is 70:30

[0054] Granules are prepared from the following raw materials in parts by weight:

[0055] Corn 30%, broken rice 15%, wheat 10%, soybean meal 10%, fermented soybean meal 5%, secondary meal 3%, spray-dried plasma protein powder 3%, steam fish meal 3%, feed grade mixed oil 2%, whey powder 5%, lactose 6%, low-protein whey powder 10%, high-fat sweet whey 6%, astragalus polysaccharide 0.5%, methionine 0.1%, lysine 0.2%, arginine 0.02%, feed small peptide 0.4%, Soybean lecithin 0.4%, fat emulsifier 900ppm, ethoxyquinoline 150ppm, dimethyl fumarate 1000ppm, glutamine 0.5%, suckling pig special compound enzyme 450ppm, vitamin A: 20000IU / kg, vitamin D 3 : 4000IU / kg, vitamin E: 60IU / kg, vitamin K 3 : 5mg / kg, vitamin B2: 10mg / kg, vitamin B6: 6mg / kg, vitamin B12: 40μg / kg, niacinamide: 50mg / kg, pantothenic acid: 30mg / kg, folic aci...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com