Method for pretreating fly ash of domestic refuse incineration through cooperative disposal of cement kilns

A domestic waste incineration and co-processing technology, applied in water/sludge/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Control and other issues, to achieve the effect of shortening the process cycle, low cost and reliable operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

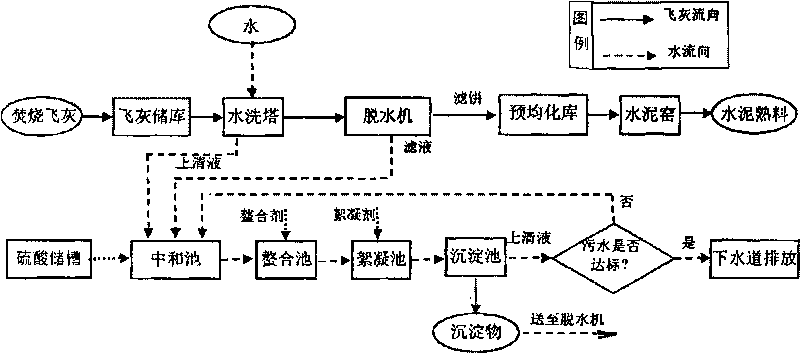

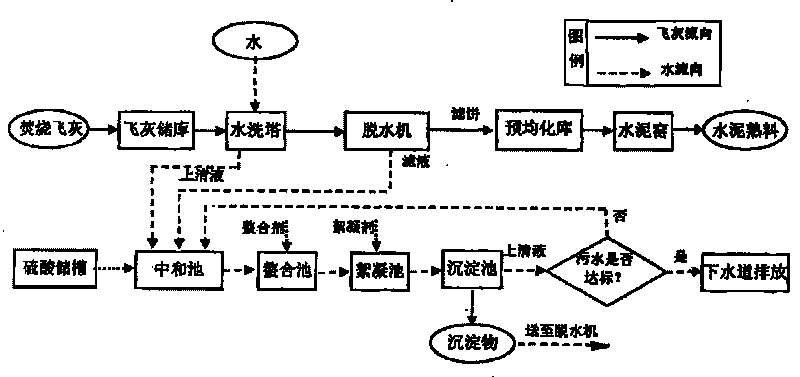

[0022] Embodiment 1 (concrete technique such as figure 1 shown)

[0023] Incineration fly ash of a municipal solid waste incineration plant, the content of Cl element is 17.96wt%, the content of Zn element is 0.54wt%, the content of Pb element is 0.23wt%, the content of Sn element is 0.12wt%, and the content of Cu element is 0.09wt%. , Cr element content is 0.09wt%.

[0024] Mix each batch of 1t incineration fly ash and water in the water washing equipment according to the weight ratio of water: ash = 4:1, stir for 10 minutes, let it stand for half an hour, then extract the supernatant into the neutralization tank, slowly add the concentration It is 20% industrial sulfuric acid, and it is stirred while adding, and the pH meter monitors and controls the sulfuric acid dripping amount in real time. After the pH reaches 6-9, transfer the solution to the chelation tank, add 1 wt% DTC chelating agent based on the fly ash mass according to the preliminary experiment, stir rapidly w...

Embodiment 2

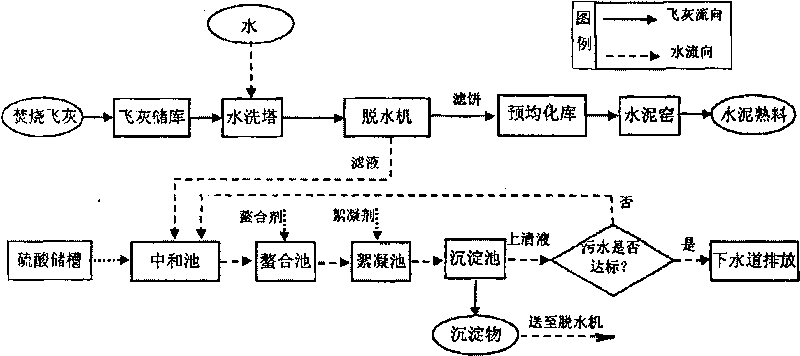

[0025] Embodiment 2 (concrete technique is as figure 2 shown)

[0026] Incineration fly ash of a municipal solid waste incineration plant, the content of Cl element is 17.96wt%, the content of Zn element is 0.54wt%, the content of Pb element is 0.23wt%, the content of Sn element is 0.12wt%, and the content of Cu element is 0.09wt%. , Cr element content is 0.09wt%.

[0027]Incineration fly ash and water are mixed in water washing equipment according to the weight ratio of water: ash = 15: 1, stirred for 10 minutes, and transferred to the vacuum belt filter press as a whole, and the water content of the press filter cake is reduced to 22.1wt%. The amount of chlorine is reduced to 0.86wt%, and it can be mixed with raw meal in an amount of 4wt%, and then directly put into kiln for calcination. Add DTC chelating agent with 1.5wt% fly ash mass according to the preliminary experiment, stir rapidly while adding, and transfer to the flocculation tank as a whole after stirring for 15...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com