Polyethylene glycol electrolyte granular preparation and production method

A technology for polyethylene glycol and granule preparations, which is applied in pharmaceutical formulations, medical preparations with non-active ingredients, and medical preparations containing active ingredients, etc. , poor treatment effect and other problems, to achieve good taste, reduce the probability of disadvantages and side effects, and achieve good results

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example 1

[0069] Preparation of Polyethylene Glycol Electrolyte Granules:

[0070] Weigh 13125g of polyethylene glycol 4000 and pulverize it, pass through a 60-mesh sieve to obtain fine particles of polyethylene glycol 4000 with a particle size (D90) of 250 μm. Weigh 178.5g of sodium bicarbonate, 350.7g of sodium chloride, 46.6g of potassium chloride, and 10g of acesulfame potassium, mix them, pulverize them, and pass through an 80-mesh sieve to obtain electrolyte fine particles with a particle size (D90) of 180 μm. After mixing the polyethylene glycol 4000 fine particles obtained above and the electrolyte fine particles uniformly according to the method of equal volume addition, use about 1371 g of 95 volume % ethanol aqueous solution to make a soft material, and then use a 40 mesh sieve to granulate, and the fluidized bed temperature is 10 ° C ~ Boiling and drying at 60° C. for 20 minutes, sizing with a 40-mesh sieve to prepare polyethylene glycol electrolyte particles with a particle...

preparation example 2~ preparation example 6

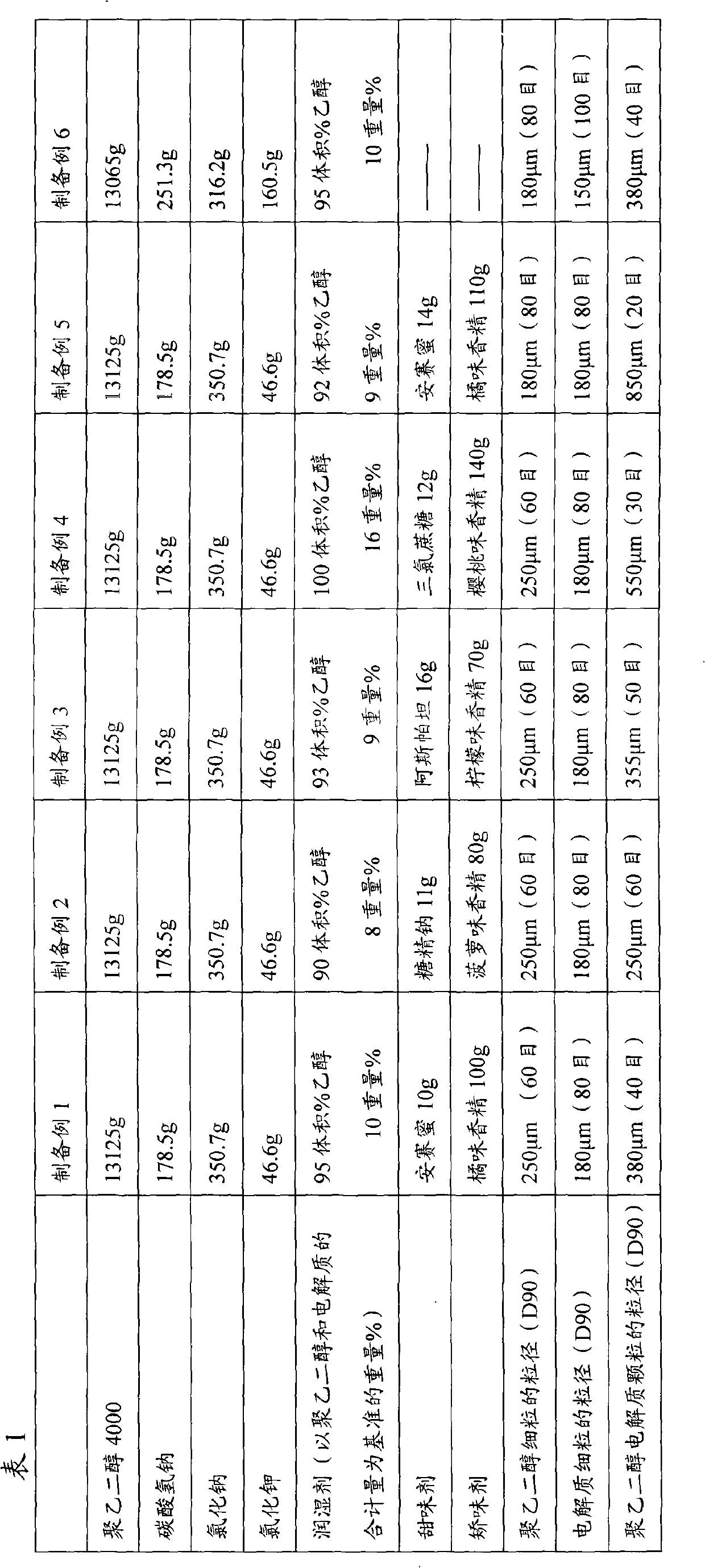

[0072] According to Table 1, change the composition and dosage of the preparation of polyethylene glycol electrolyte granule preparations, and the type of sieve used, and follow the same operation steps as in Preparation Example 1 to manufacture the polyethylene glycol electrolyte particles of Preparation Examples 2 to 6. Alcohol electrolyte granular preparation.

[0073]

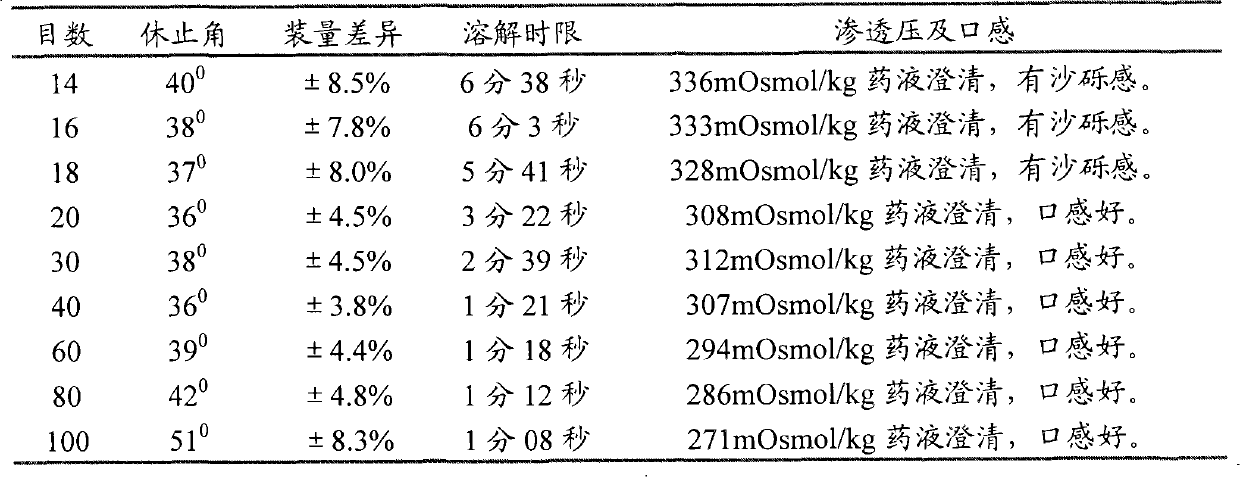

[0074] Hereinafter, the technical effect of the polyethylene glycol electrolyte particle preparation and the manufacturing method thereof of the present invention will be further described through test examples.

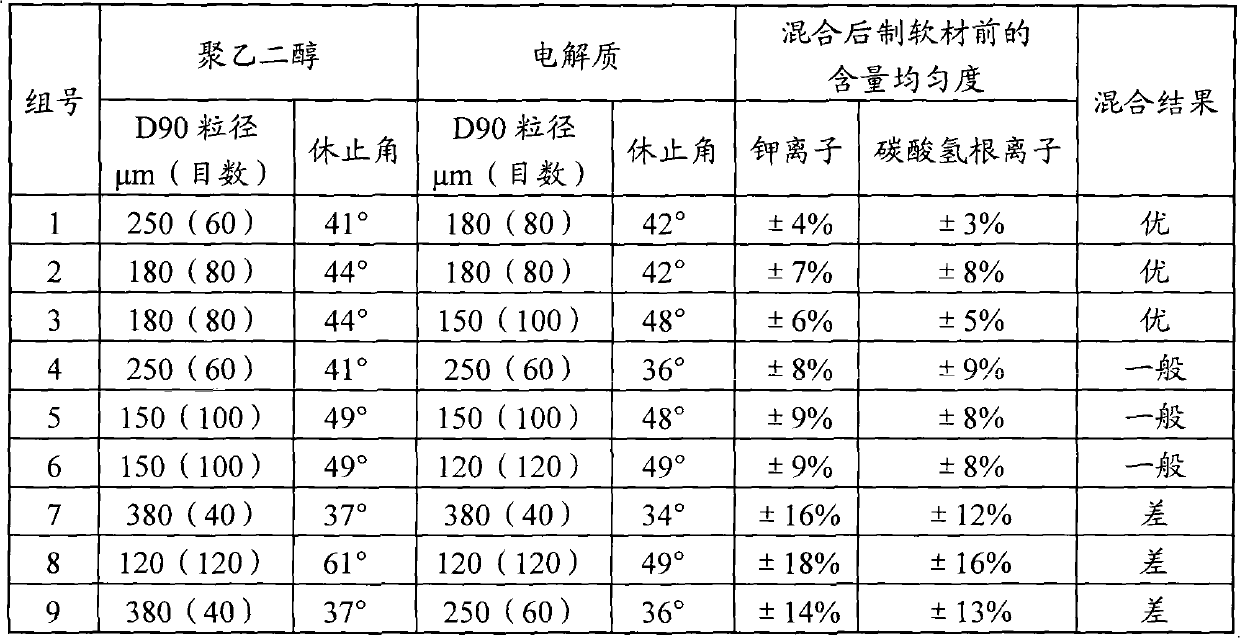

[0075] In the present invention, the evaluation method of fluidity (angle of repose) is as follows.

[0076]

[0077] Take the sample particles and flow them into a circular watch glass from a fixed small funnel until the highest cone is obtained. Measure the height H and radius R of the cone, and calculate the angle of repose α according to the following formula. The larger the angle of rep...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com