Silicon dioxide nano rod enhanced and toughed polyester compound material and preparation method thereof

A polyester composite material, strengthening and toughening technology, which is applied in the field of polymer materials, can solve the problem of not finding silica nanorods reinforced and toughened polyester composite materials, etc., achieves improved mechanical properties, improved impact performance, and avoids agglomeration. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

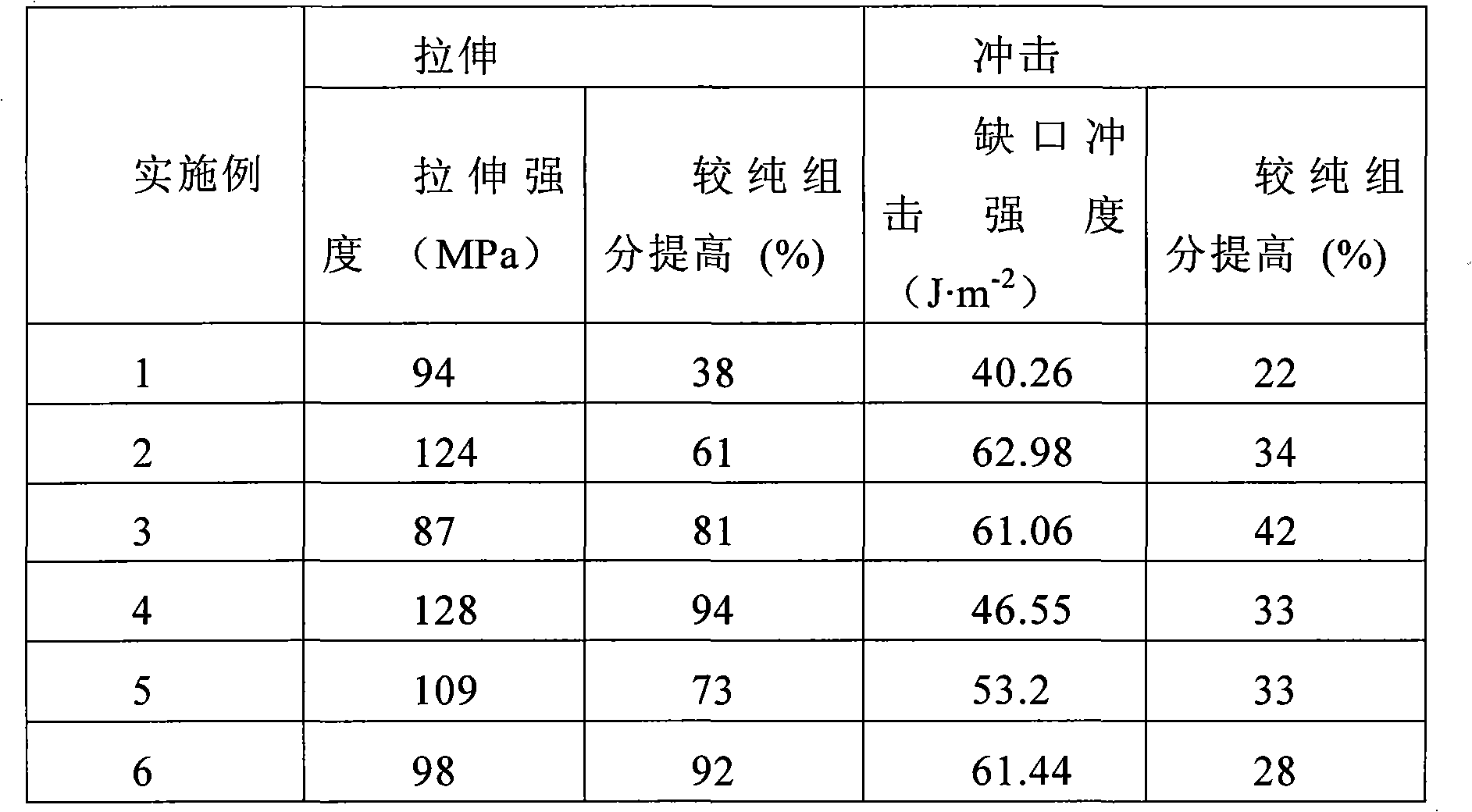

Examples

Embodiment 1

[0031] Add 41.1g methyl orthosilicate and 10mL deionized water into the beaker, and stir vigorously for 5 minutes, 88mL ethanol and 1mL 0.2mol·L -1 Dilute hydrochloric acid was added into the beaker together, ultrasonicated for 30 minutes, and placed in an environment of 50° C. for 10 minutes to obtain an inorganic filler precursor (sol). Stand still and set aside.

[0032] 776.8g of dimethyl 1,2-phthalate, 541.2mL of ethylene glycol, catalyst zinc acetate, and tetrabutyl titanate (each 300ppm) were added to the polymerization kettle. (Note: this polymerization kettle is equipped with stirring device, nitrogen input device and fractionation device). The temperature was raised to 190°C, and the reaction was carried out for 4 hours until methanol no longer distilled off. Add 8 g of the above-mentioned sol and antioxidant (168) to the system, slowly raise the temperature to 230° C., lower the pressure to 0.01 MPa, and react for 1 hour. Subsequently, the temperature of the syst...

Embodiment 2

[0034] Add 56.3g tetraethyl orthosilicate and 12mL deionized water into the beaker, and stir vigorously for 5 minutes, 100mL acetone and 2mL 0.2mol·L -1 Dilute hydrochloric acid was then added to the beaker, ultrasonicated for 40 minutes, and placed in an environment of 78° C. for 10 minutes to obtain an inorganic filler precursor (sol). Stand still and set aside.

[0035] 1425.6g of dimethyl 2,6-naphthalene dicarboxylate, 994.8mL of propylene glycol, catalyst calcium acetate, and tetrabutyl titanate (500ppm each) were added to the polymerization kettle. (Note: this polymerization kettle is equipped with stirring device, nitrogen input device and fractionation device). The temperature was raised to 160° C., and the reaction was carried out for 6 hours until methanol no longer distilled off. Add the above-mentioned sol and 9 g of anti-aging agent into the system, slowly raise the temperature to 220° C., lower the pressure to 0.02 MPa, and react for 1 hour. Subsequently, the ...

Embodiment 3

[0037] Add 71.4g propyl orthosilicate and 10mL deionized water into the beaker, and stir vigorously for 5 minutes, then add 180mL acetone and 2mL formic acid into the beaker together, ultrasonicate for 52 minutes, and place in an environment of 98°C for 10 minutes to obtain Inorganic filler precursor (sol). Stand still and set aside.

[0038]776.8g of dimethyl 1,3-phthalate, 785.4mL of butanediol and catalyst cobalt acetate, tetrabutyl titanate (each 300ppm) were added into the polymerization kettle. (Note: this polymerization kettle is equipped with stirring device, nitrogen input device and fractionation device). The temperature was raised to 200°C, and the reaction was carried out for 5.5 hours until no methanol distilled out. Add the above-mentioned sol and 9 g of light stabilizer to the system, slowly raise the temperature to 210° C., lower the pressure to 0.03 MPa, and react for 1 hour. Subsequently, the temperature of the system was raised to 240° C., the pressure wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com