Cooperatively preprocessing method of solid waste incineration flying ash cement kiln of returned effluent

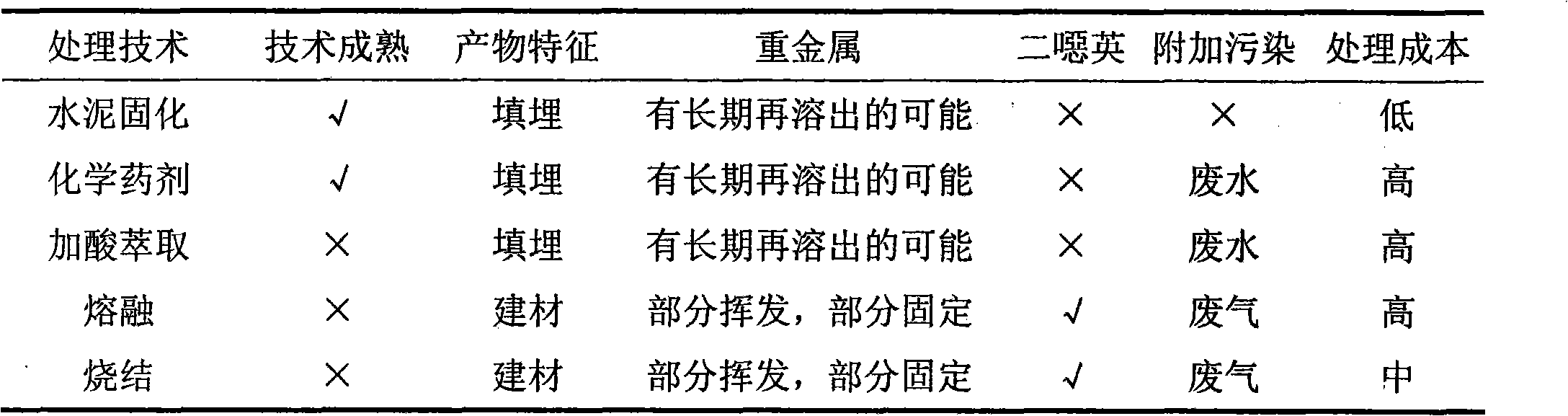

A technology of domestic waste incineration and cement kiln, which is applied in water/sludge/sewage treatment, water/sewage treatment, neutralized water/sewage treatment, etc. Control and other issues to achieve stable treatment effect, saving investment and saving water.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

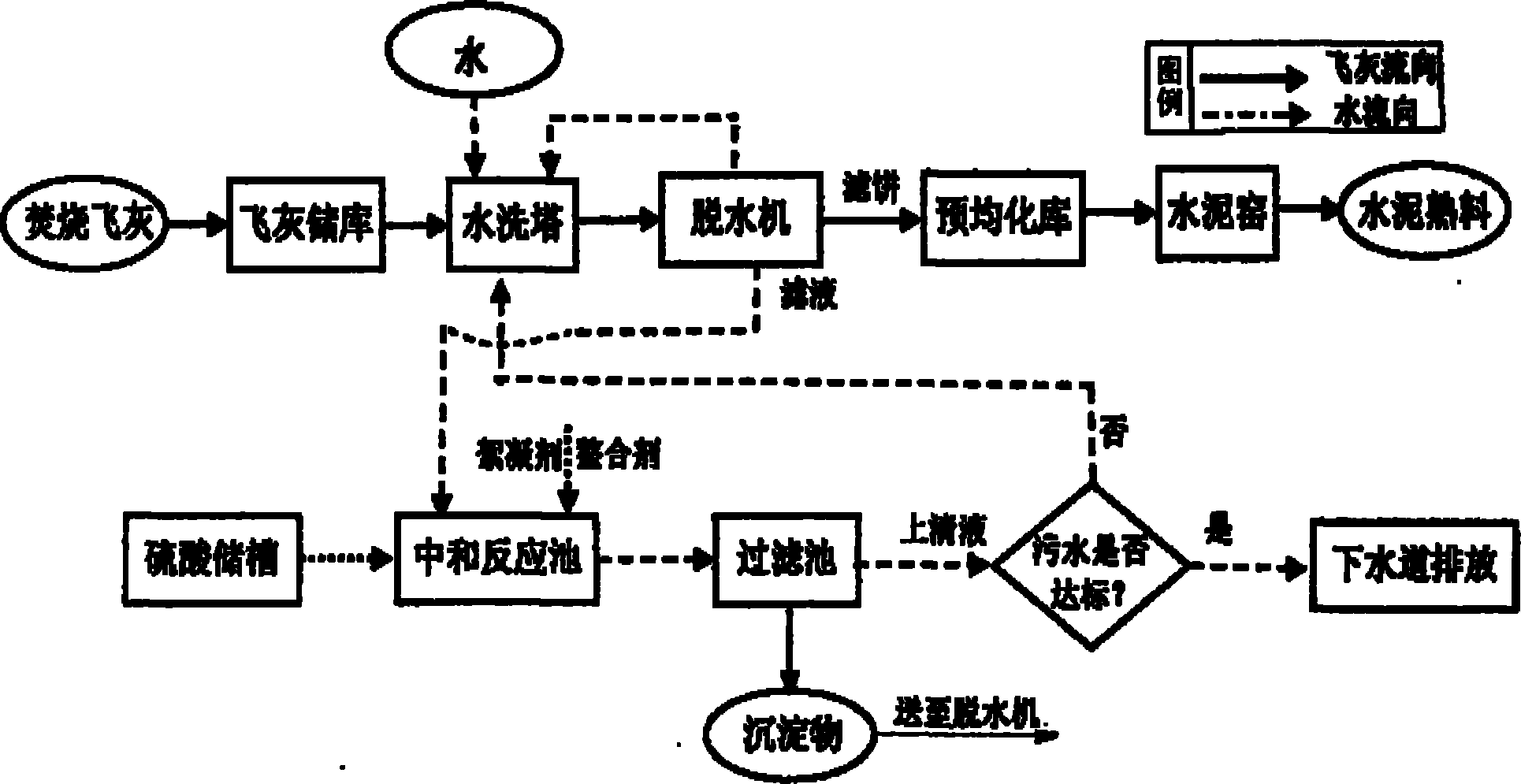

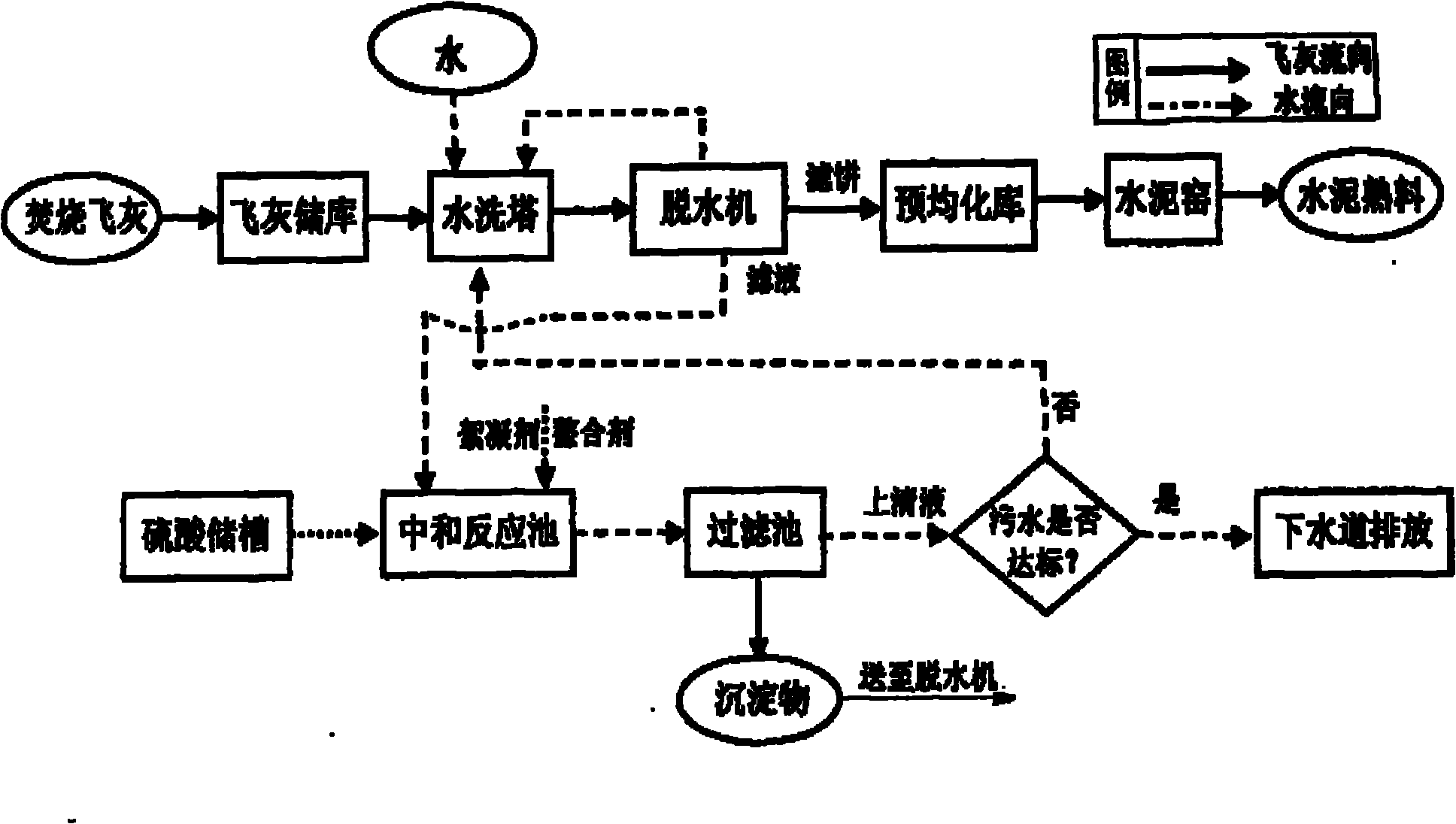

Method used

Image

Examples

Embodiment

[0033]The incineration fly ash of a municipal solid waste incineration plant has a water content of 1.67wt%, a Cl element content of 19.66wt%, a Zn element content of 0.48wt%, a Pb element content of 0.19wt%, and a Sn element content of 0.16wt%. , Cu element content is 0.10wt%, Cr element content is 0.10wt%.

[0034] Water and incineration fly ash were mixed in water washing equipment according to the weight ratio of water: ash=15:1, stirred for 10 minutes, and transferred to a vacuum belt filter press as a whole, and the water content of the press filter cake was reduced to 20.2wt%. The amount of chlorine is reduced to 1.03wt%, and it can be mixed with raw meal and directly put into kiln for calcination.

[0035] The filtrate was returned to the water washing tower for reuse, and after being reused 5 times, it was introduced into the neutralization reaction tank, and industrial sulfuric acid with a concentration of 20wt% was slowly added, stirred while adding, and the pH mete...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com