Method for deeply deashing cock

A coke and depth technology, which is applied in the field of coke deep deashing, can solve the problem that there is no good method for deashing finished coke, and achieve the effect of high added value, low energy consumption and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

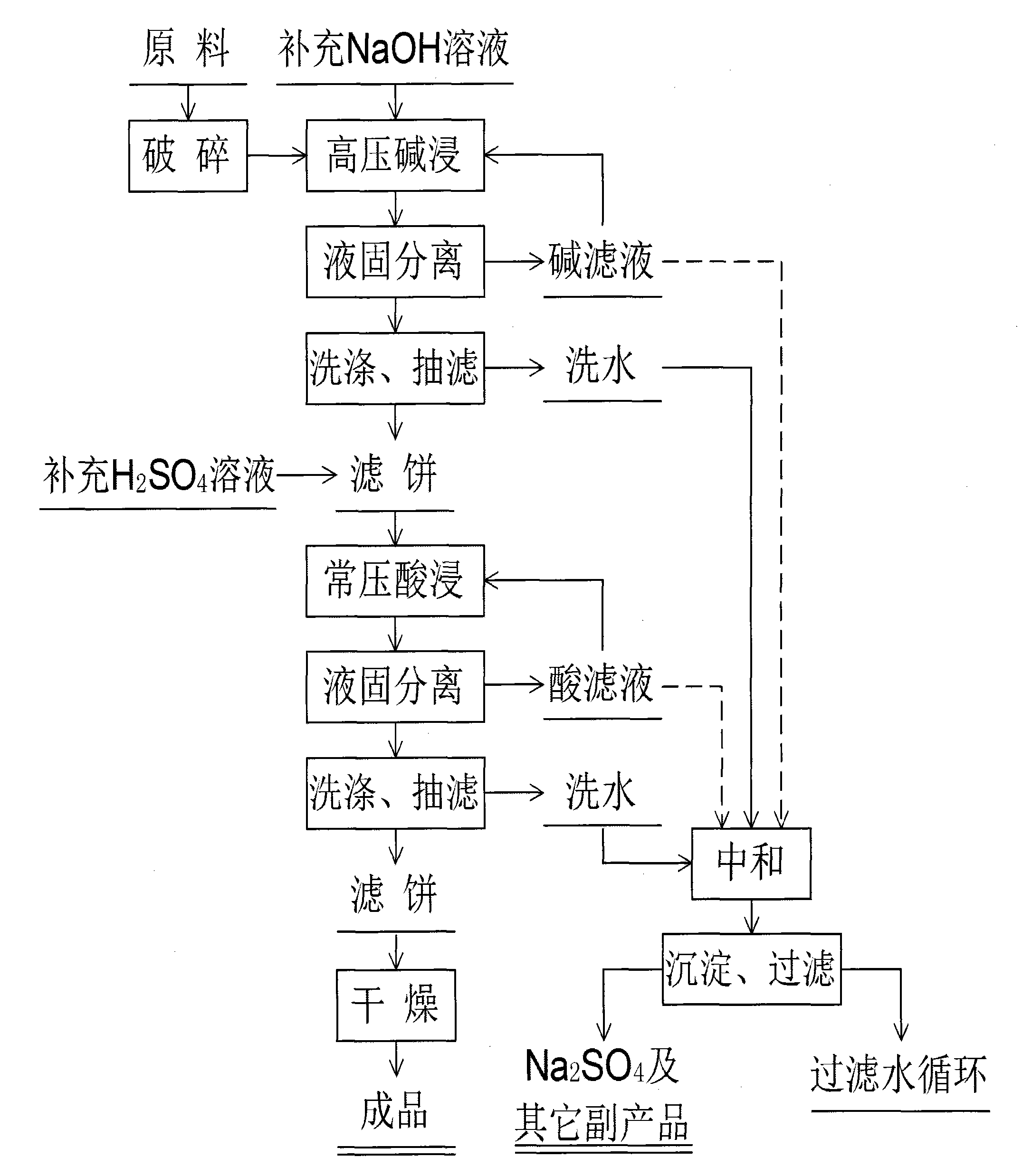

Method used

Image

Examples

Embodiment 1

[0045] (1) Raw materials:

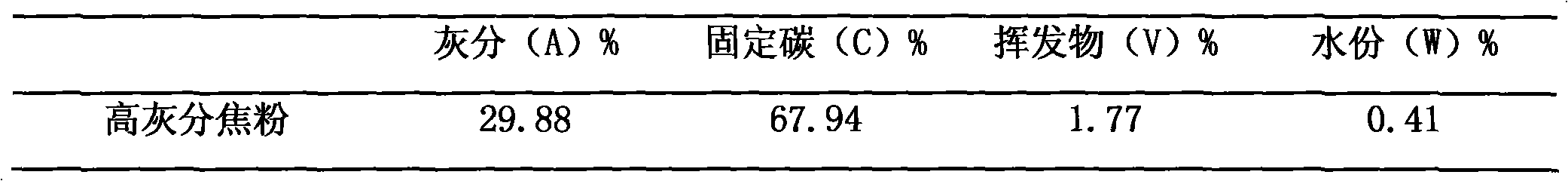

[0046] The raw material is high-ash coke powder produced during screening in a coking plant, which is crushed to a particle size of less than 2mm. Its composition is shown in Table 1

[0047] Table 1 raw material composition list

[0048]

[0049] (2) Experimental conditions

[0050] ① Alkaline leaching conditions: the mass concentration of sodium hydroxide aqueous solution is 15%, the liquid-solid ratio is 6:1, the temperature is 110°C, the pressure is 0.8MPa, and the leaching time is 40min.

[0051] ②Acid leaching conditions: the mass concentration of sulfuric acid aqueous solution is 12%, the liquid-solid ratio is 6:1, the temperature is 80°C, and the leaching time is 30 minutes.

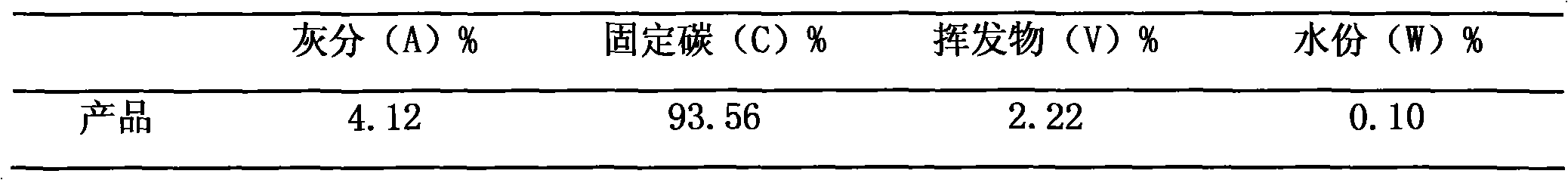

[0052] (3) Experimental results:

[0053] Under certain conditions, experiments are carried out to obtain alkali leaching slurry, and the slurry is filtered to obtain primary leaching intermediate product coke powder and alkali leaching solution. After the coke...

Embodiment 2

[0057] (1) Raw materials:

[0058] The raw material is diced coke with a particle size of about 5 cm produced during crushing in a coking plant, which is crushed to a particle size of less than 2 mm. Its composition is shown in Table 3.

[0059] Table 3 raw material composition table

[0060]

[0061] (2) Experimental conditions

[0062] ①Alkaline leaching conditions: The mass concentration of sodium hydroxide aqueous solution is 10%, the liquid-solid ratio is 3:1, the temperature is 150°C, the pressure is 1.0MPa, and the leaching time is 30min.

[0063] ②Acid leaching conditions: the mass concentration of sulfuric acid aqueous solution is 8%, the liquid-solid ratio is 3:1, the temperature is 70°C, and the leaching time is 20 minutes.

[0064] (3) Experimental results:

[0065] Under certain conditions, experiments are carried out to obtain alkali leaching slurry, and the slurry is filtered to obtain primary leaching intermediate product coke powder and alkali leaching ...

Embodiment 3

[0069] (1) Raw materials:

[0070] The raw material is high-ash bituminous coal from a coal mine in a certain place, which is crushed to a particle size of less than 2mm. Its composition is shown in Table 5.

[0071] Table 5 Raw material composition list

[0072]

[0073] (2) Experimental conditions

[0074] ①Alkaline leaching conditions: The mass concentration of sodium hydroxide aqueous solution is 10%, the liquid-solid ratio is 6:1, the temperature is 180°C, the pressure is 1.4MPa, and the leaching time is 1h.

[0075] ②Acid leaching conditions: the mass concentration of sulfuric acid aqueous solution is 10%, the liquid-solid ratio is 2:1, the temperature is 80°C, and the leaching time is 30 minutes.

[0076] (3) Experimental results:

[0077] Under certain conditions, experiments are carried out to obtain alkali leaching slurry, which is filtered to obtain primary leaching intermediate product coal powder and alkali leaching solution. After the coal powder is washe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com