Cleaning production process of iminodiacetic acid

A technology of iminodiacetic acid and sodium iminodiacetate is applied in the field of preparation of chemical product intermediate iminodiacetic acid, which can solve the problems of corrosion of stirring equipment, high consumption of raw materials and high cost, and achieves production cost saving and no three wastes Pollution, good quality effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

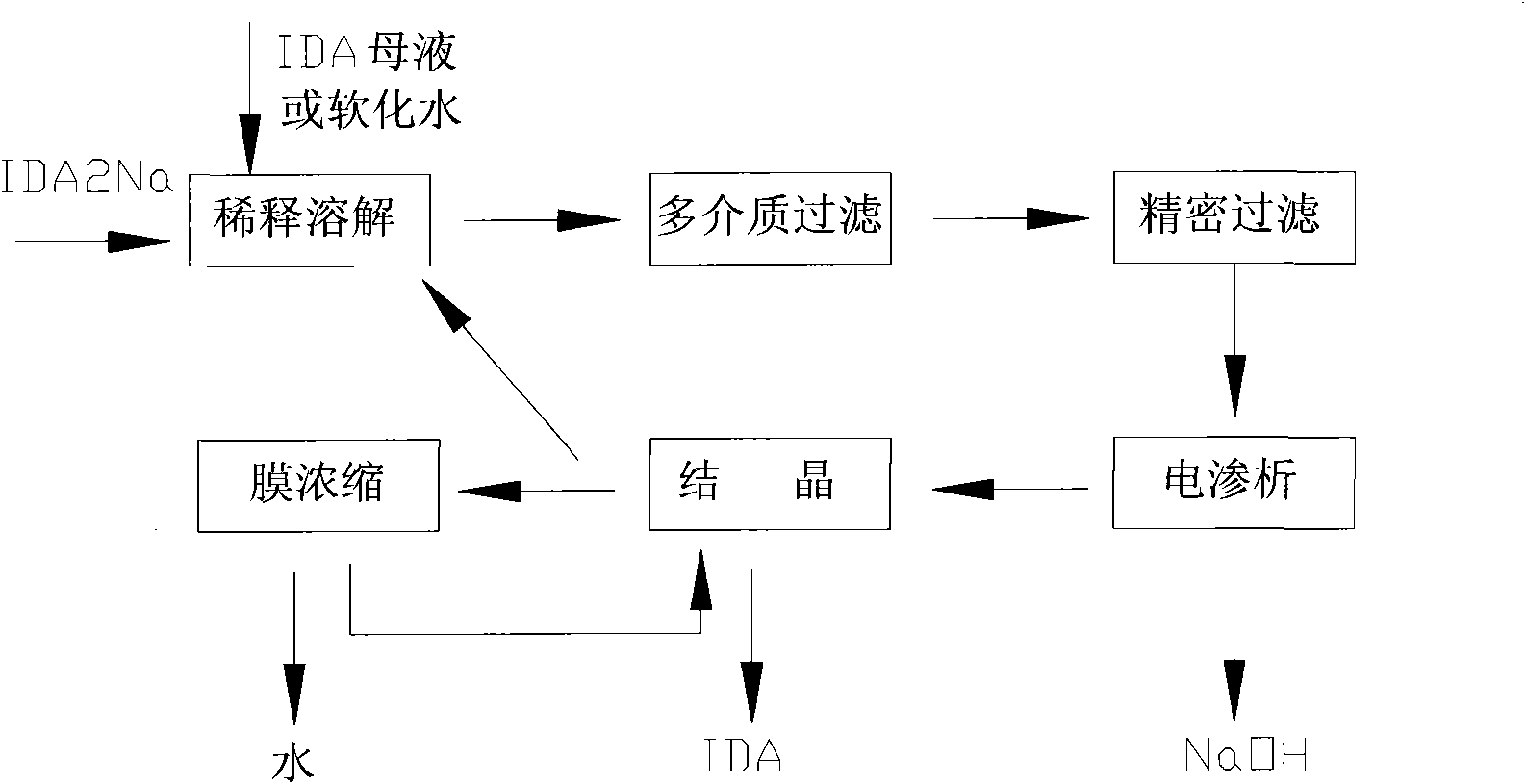

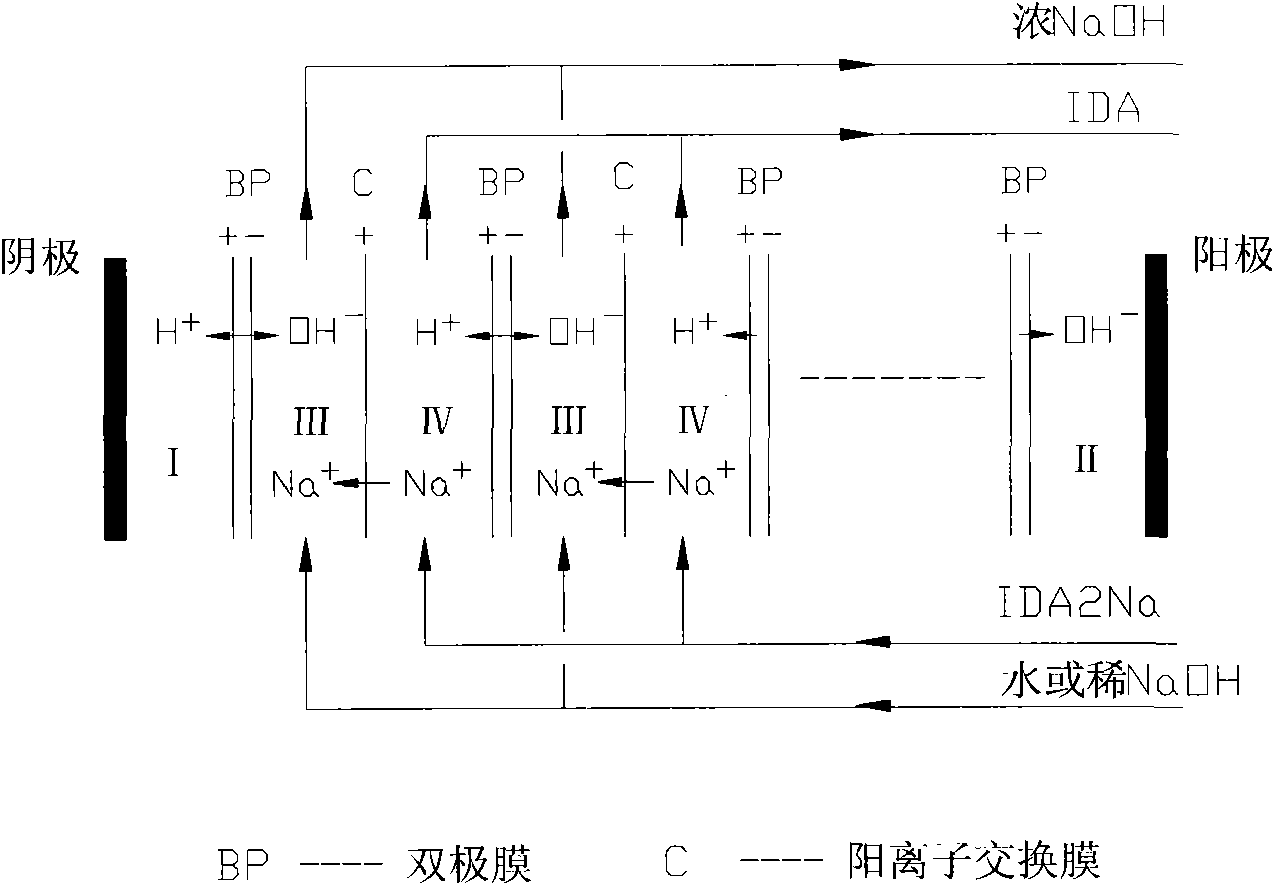

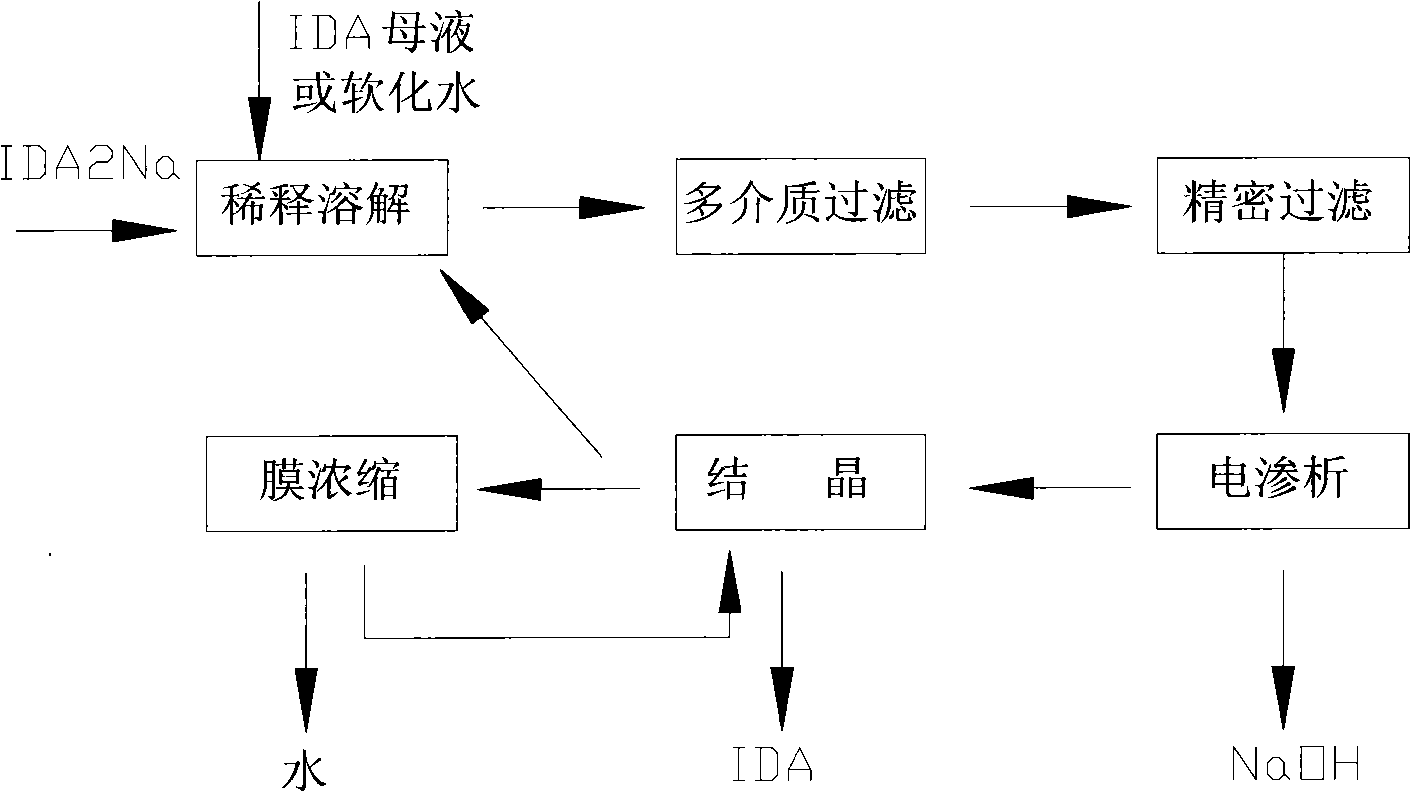

[0013] Example 1: refer to the attached figure 1 and 2 . A clean production process of iminodiacetic acid, using iminodiacetic acid sodium salt as raw material, adopting membrane integration technology to prepare iminodiacetic acid, the specific process steps are as follows:

[0014] 1) Using iminodiacetic acid sodium salt as raw material, add demineralized water or crystallized diacetic acid mother liquor, dilute the mass percentage of iminodiacetic acid sodium salt to 5% to 30% and include the end value, such as 5%, 6% %, 7%, 8%, 9%, 10%, 11%, ..., 26%, 27%, 28%, 29%, 30%, and include the decimal point value that constitutes 1;

[0015] 2) The solution of step 1) passes through a multimedia filter containing activated carbon at a flow rate of 2 to 20m / h to remove mechanical impurities and viscous substances, and then passes through one or more of a precision filter, a microporous filter, and an ultrafiltration membrane. Several combinations of filtration to remove micron,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com