Dawsonite-based polyvinyl chloride composite heat stabilizer and application thereof

A compound heat stabilizer and polyvinyl chloride technology, which is applied in the field of compound heat stabilizers, can solve problems such as difficult promotion and application, and achieve the effects of easy application and promotion, simple production process and good compatibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0032] Synthesis of dawsonite:

[0033] In a 500mL flask, add 200mL water and 15.9g anhydrous sodium carbonate (0.15mol), stir and heat up to 70~80℃ to control constant, add 17.1g nearly saturated aluminum sulfate solution (0.05mol) with solid content of 17.1g, stir to react After 1h, add a nearly saturated sodium bicarbonate solution (0.1mol) with a solid content of 8.4g, stir and react for 3h, then add stearic acid with a mass of 3% of the precipitate, continue to stir and react for 0.5h, the reaction product is filtered, After washing, dehydrating and drying at 75°C, it is crushed to pass a 200-mesh sieve to obtain dawsonite products.

Embodiment 2~7 and comparative example 1~6

[0035] Preparation of composite heat stabilizer:

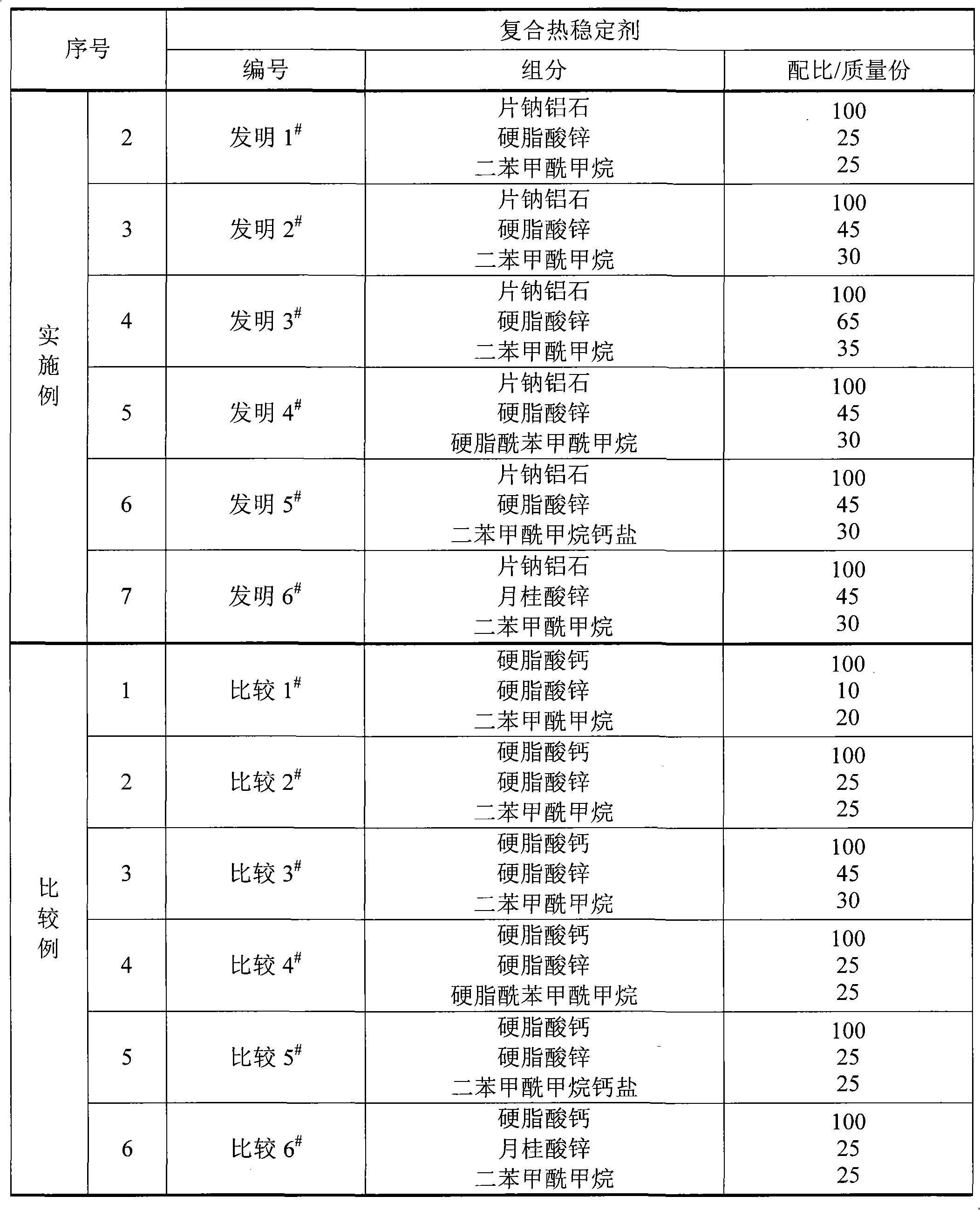

[0036] According to the formula shown in Table 1, each component material was added to a portable high-speed Chinese medicine pulverizer and mixed evenly to obtain the dawsonite-based composite heat stabilizer of the present invention and the calcium-zinc soap heat stabilizer for comparison.

[0037] Table 1 Compound heat stabilizer formula

[0038]

Embodiment 8~14 and comparative example 7~12

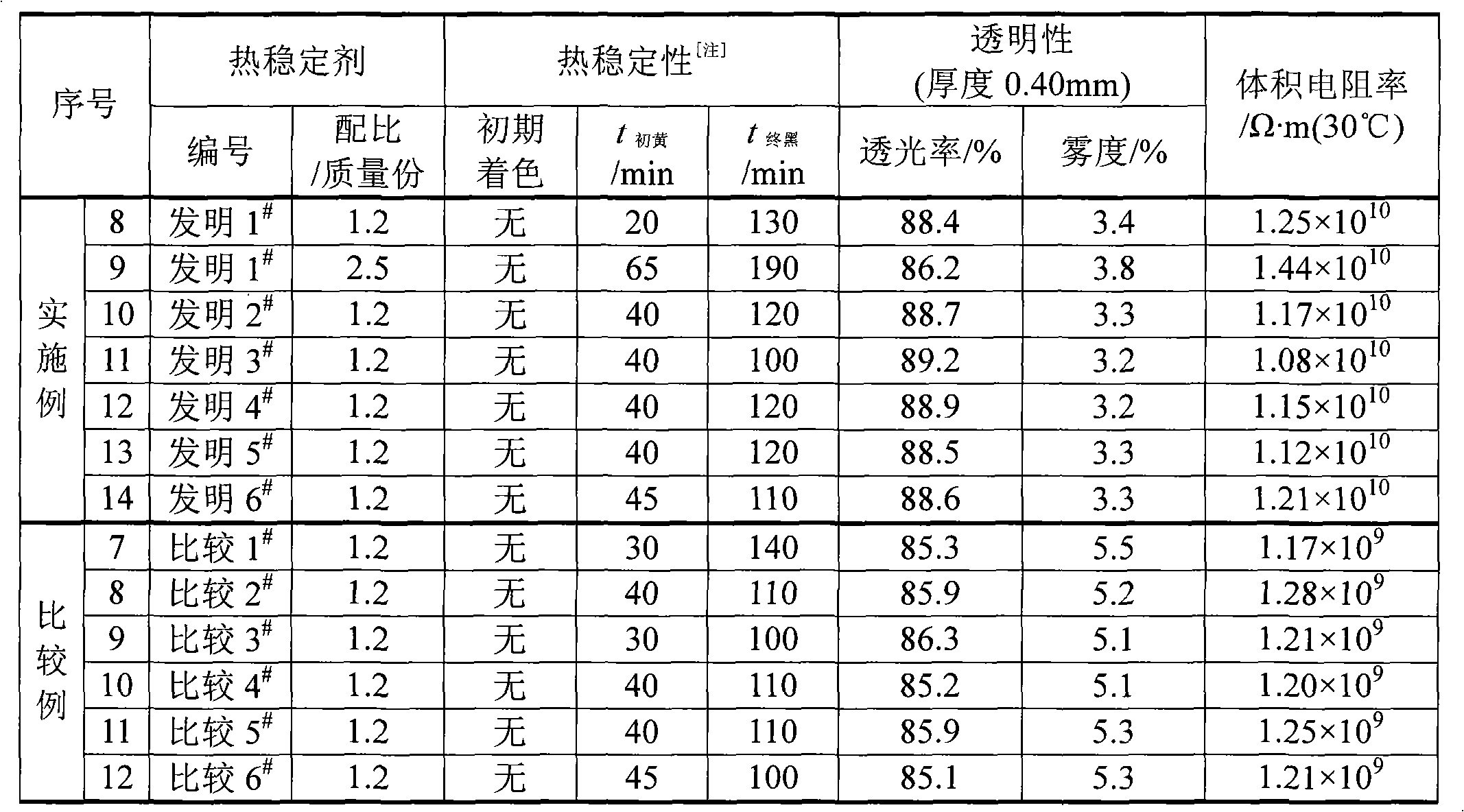

[0040] Thermal stabilizer performance test:

[0041] The application performance of the dawsonite-based composite heat stabilizer of the present invention and the calcium-zinc soap composite heat stabilizer for comparison is tested according to the following methods:

[0042] 1. Sample formulation and preparation

[0043] Sample formula:

[0044] Component ratio / parts by mass

[0045] Polyvinyl chloride resin (SG-5 type) 100

[0046] Dioctyl phthalate (DOP) 50

[0047] Epoxidized soybean oil (ESBO) 3

[0048] Heat stabilizer see table 2

[0049] Sample preparation: Add the materials to the high-speed mixer according to the formula, knead evenly, and then masticate the mixture on a plastic mill at 160°C for 5 minutes, and then pull it into a test piece with a thickness of about 1 mm for use.

[0050] 2 Thermal stability test

[0051] Refer to ASTM2115-67, place the test piece on the aluminum sheet, heat it at a constant temperature of 180℃ in a heat aging test box, and take samples at regular ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com