Membrane electrode for water electrolysis and preparation method thereof

A membrane electrode and electrolyte technology, applied in the field of membrane electrode and its preparation, can solve the problems of high cost, high cost, and restrictions on the wide use of SPE electrolyzers, and achieve the effects of low cost, reduced requirements, and small volume

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

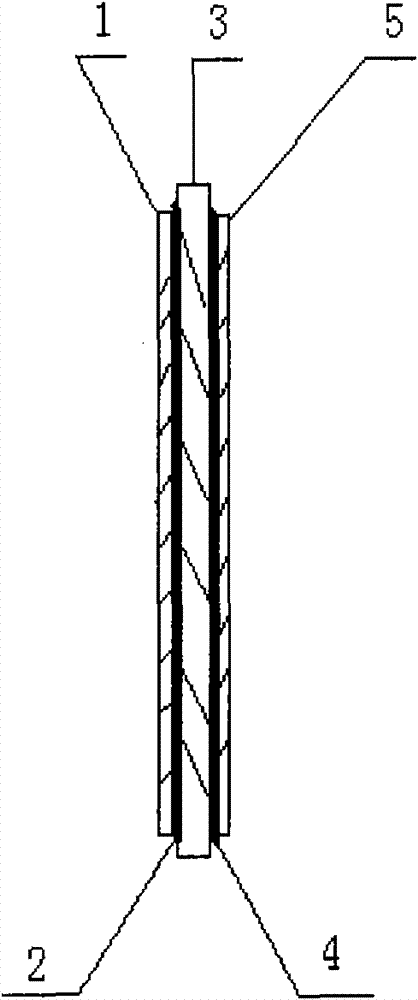

[0045]The preparation method of the membrane electrode provided by the present invention includes coating a catalyst slurry containing a catalyst, a membrane solution, a binder and a solvent on a porous support layer to form a cathode and an anode catalytic electrode, and stacking the cathode and anode catalytic electrodes respectively to both sides of the basic polymer anion exchange membrane, and then pressed together by a hot press to form a three-in-one membrane electrode.

[0046] In the present invention, the introduction of the support layer improves the mechanical strength of the membrane electrode, increases the pressure resistance range of the electrolytic cell during electrolysis of water, and can also be used as a carrier for catalyst attachment. The support layers for the cathode and anode can be the same or different. The support layer can be divided into carbon fiber-based and metal-based support layers. Carbon fiber includes carbon paper, carbon cloth, carbon ...

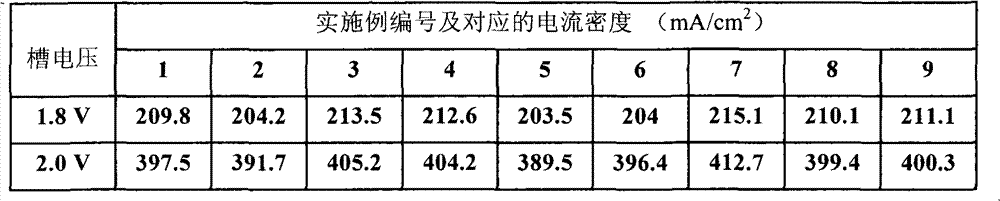

Embodiment 1

[0071] 1) Cut 5×5cm as needed 2 of carbon paper (Toray TGP-H-060, Japan).

[0072] 2) Preparation of catalyst layer slurry

[0073] Anode catalytic layer slurry: Ni and Fe hydroxide catalyst (the molar ratio of nickel hydroxide and iron hydroxide in the catalyst is 2:1), binder polyethylene glycol solution (polyethylene glycol in the binder) The content of the dry film is 2wt%), the film solution (trimethyl quaternized polyetheretherketone solution, the content of the dry film is 8wt%, the solvent is a mixture of ethanol and DMF, and the mass ratio is 2:1), ethanol according to mass The mixture was mixed in a ratio of 1:10:5:5, and was stirred in an ultrasonic cleaner for 40 min with ultrasonic waves to obtain a uniformly mixed anode oxygen evolution catalyst slurry.

[0074] Cathode catalytic layer slurry: Ni, Cr and Mo metal alloy catalyst (the molar ratio of Ni, Cr and Mo in the catalyst is 2:2:1), binder polyurethane solution (the content of polyurethane in the binder is 8...

Embodiment 2

[0079] 1) Cut 5×5cm as needed 2 of carbon paper (Toray TGP-H-090, Japan).

[0080] 2) Preparation of catalyst layer slurry

[0081] Anode catalytic layer slurry: Ni and Fe oxide catalyst (the molar ratio of nickel oxide and iron oxide in the catalyst is 2:1), binder polyurethane solution (the content of polyurethane in the binder is 4wt%), membrane solution (trimethyl quaternized polysulfone membrane solution, the content of the dry film is 6wt%, the solvent is a mixture of ethanol and DMF, and the mass ratio is 3:1), ethanol is mixed according to the mass ratio of 1:5:10:5, And stirring for 60min while ultrasonic in an ultrasonic cleaner to obtain a mixed anode catalyst slurry.

[0082] Cathode catalytic layer slurry: Ni, Co and Mo metal alloy catalyst (the molar ratio of Ni, Co and Mo in the catalyst is 5:3:1), binder polyurethane solution (the content of polyurethane in the binder is 6wt%) ), membrane solution (trimethyl quaternized polysulfone membrane solution, the con...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com