Coarse grained oil removing method for Lurgi gasifier coal gasification wastewater

A coarse-grained, coal-to-gas technology, which is applied in gaseous effluent wastewater treatment, separation methods, grease/oily substances/float removal devices, etc., can solve the problems of high cost, secondary pollution, poor treatment effect, etc. Achieve high utilization rate, small packing loss and good compression resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

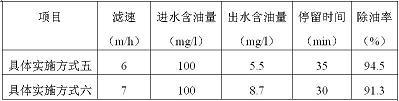

[0017] Specific embodiment one: the method for coarse-grained degreasing of coal-to-gas waste water in the Luqi furnace in this embodiment is carried out according to the following steps: 1. Fill coarse-grained fillers in the coarse-grained device, wherein the coarse-grained fillers are fruit shells , the thickness of the coarse-grained filler is 0.4~0.8 times the height of the coarse-grained device (that is, 2 / 5~4 / 5 of the height of the coarse-grained device); It is transported to the coarse granulation device equipped with coarse granulation filler. The coarse granulation device adopts lower water inlet and upward flow filtration, the filtration rate is 6~7m / h, and the water treatment time of the coarse granulation device is 20~40min , which realizes the deoiling of Lurgi furnace coal gasification wastewater.

[0018] The coarse-grained filler in the coarse-grained device of this embodiment uses pebbles as the supporting layer, and the pebbles can be purchased from the marke...

specific Embodiment approach 2

[0023] Specific embodiment two: the difference between this embodiment and specific embodiment one is: the shell in step one is a walnut shell. Other steps and parameters are the same as those in Embodiment 1.

specific Embodiment approach 3

[0024] Embodiment 3: This embodiment differs from Embodiments 1 to 2 in that the thickness of the coarse-grained filler in step 1 is 0.5 times the height of the coarse-grained device. Other steps and parameters are the same as those in Embodiments 1 to 2.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com